Introduction:

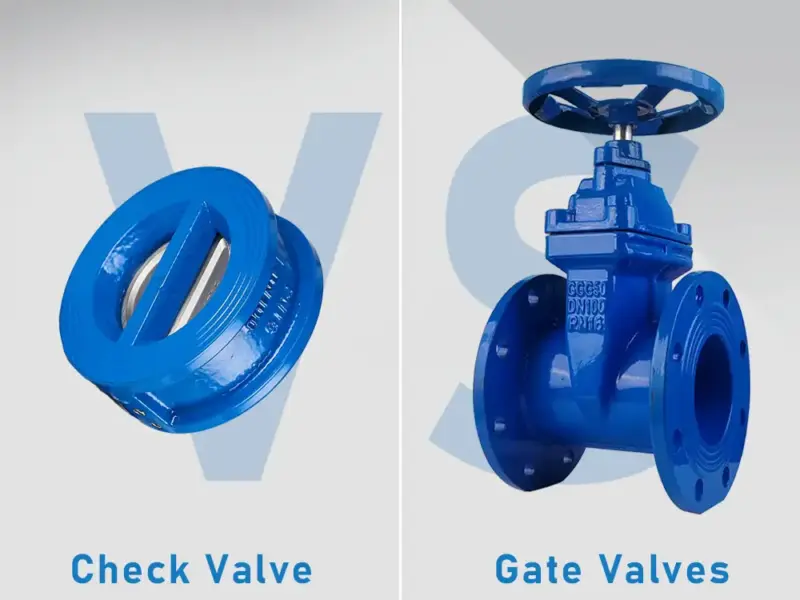

Valves play a crucial role in controlling the flow of fluids in various industries. They ensure the efficiency and safety of operations. Different types of valves are available in the market. However, the two commonly used options are check valves and gate valves. Check valve VS gate valve; which is better? In this article, we will understand their characteristics and applications. We will also look into their advantages and disadvantages. Further, we will introduce check and gate valves to determine which best suits your purpose.

Check Valve Overview

The check valve is also known as a non-return or one-way valve. Its design allows fluid to flow in one direction while preventing backflow. It means it doesn’t allow flow in the opposite direction. The mechanism typically involves a flap, disc, or piston. It opens when fluid flows in the desired direction and closes to prevent reverse flow. Check valves come in various designs. Some are swing check valves, lift check valves and ball check valves.

Characteristics of Check Valves

-

Simple Design

Check valves are often characterized by a straightforward design. They comprise fewer components compared to some other valve types.

-

Automatic Operation

The check valve operates automatically in response to fluid flow. This eliminates the need for external control mechanisms.

-

Quick response

Check valves respond rapidly to changes in fluid flow. This makes them suitable for applications where there is a requirement for immediate action.

Applications of Check Valves

-

Water and wastewater treatment

Check valves are vital in water plants. They are also pivotal wastewater treatment plants. This is because they prevent the backflow of contaminated water.

-

HVAC systems

Check valves play a crucial role in the heating and ventilation industries. They are also important in air conditioning systems to maintain proper fluid circulation.

-

Oil and gas industry

In the oil and gas sector, check valves help control the flow of fluids. They are important for pipelines to prevent reverse flow.

Advantages and Disadvantages of Check Valves

Advantages:

- Automatic operation reduces the need for external control systems.

- Quick response time ensures efficient flow control.

- Versatile applications across various industries.

Disadvantages:

- Limited control over fluid flow compared to some other valve types.

- There is potential for water hammer in some applications.

Gate Valve Overview

A gate valve is a linear motion valve that controls the flow of fluids by raising or lowering a gate-like disc. This wedge-like structure helps into or out of the flow path. Gate valves are known for providing a tight seal when closed. This allows unrestricted flow when fully open. These valves are used in applications where on/off control is necessary.

Characteristics of Gate Valves

-

Linear motion

Gate valves operate with a linear motion. This makes them suitable for applications requiring a clear and unobstructed flow.

-

Tight seal

When fully closed, gate valves provide a tight seal. They can prevent the passage of fluids in either direction.

-

On/off control

Gate valves are primarily designed for on/off control. Modulation of flow is only their secondary function.

Applications of Gate Valves

-

Water distribution systems

Gate valves are commonly used in water distribution systems. This is because they can provide a complete shut-off.

-

Oil and gas pipelines

In the oil and gas industry, gate valves control the flow of crude oil and natural gas.

-

Steam systems

Gate valves are suitable for applications involving high-pressure steam systems.

Advantages and Disadvantages of Gate Valves

Advantages:

- Full and unobstructed flow when fully open.

- A tight seal prevents leakage in closed positions.

- Suitable for high-pressure applications.

Disadvantages:

- Slower response time compared to check valves.

- Prone to wear and tear in frequent cycling applications.

Gate Valve VS Check Valve: A Comparative Analysis

It is essential to consider specific factors to determine which valve is superior. Some of them are application requirements, fluid characteristics, and operational considerations.

1. Check Valve VS Gate Valve- Fluid Flow Control

Check Valve

Check valves are efficient in preventing backflow. However, they offer limited control over the rate of fluid flow. They are better suited for applications where on/off control is sufficient.

Gate Valve

Gate valves provide precise control over fluid flow. This makes them suitable for applications where modulation of flow rates is essential. However, their design may not be ideal for applications requiring rapid response.

2. Gate Valve VS Check Valve- Applications

Check Valve

Check valves are commonly employed where backflow prevention is critical. In water and wastewater treatment plants, they prevent contamination. This ensures the integrity of the system.

Gate Valve

Gate valves are good for applications where a complete shut-off is essential. Examples are water distribution systems and high-pressure steam systems.

3. Check Valve VS Gate Valve- Response Time

Check Valve

Check valves respond quickly to changes in fluid flow. This makes them ideal for applications where immediate action is necessary.

Gate Valve

Gate valves have a slower response time due to their linear motion operation. This characteristic may be a limitation in applications where rapid adjustments are crucial.

4. Gate Valve VS Check Valve- Maintenance Considerations

Check Valve

Check valves have a simple design and fewer moving parts. They often require less maintenance. However, they may be susceptible to issues like water hammer in some scenarios.

Gate Valve

Gate valves may require more frequent maintenance. This is due to wear and tear, especially in applications with frequent cycling. Regular inspections and lubrication are essential to ensure optimal performance.

Considerations for Specific Applications

1. Water Treatment Plants

Check Valve

In water treatment plants, preventing backflow is crucial. This is to maintain the purity of treated water. Check valves are useful in situations where immediate closure of flow is necessary. This is to prevent contamination. The automatic operation of check valves ensures a rapid response to changes in fluid flow. This contributes to the overall efficiency of water treatment processes.

Gate Valve

Gate valves may not be the primary choice for preventing backflow. However, their precise control over flow rates can be valuable in water treatment. Gate valves can help in on/off control in specific sections of the treatment process. , allowing operators to fine-tune the flow as needed.

2. Oil and Gas Pipelines

Check Valve

In oil and gas pipelines, preventing the backward movement of fluids is critical. This is why check valves are crucial here. These valves ensure that the transported substances, such as crude oil and natural gas, flow in a unidirectional manner. It helps in maintaining the integrity of the pipeline and preventing potential hazards.

Gate Valve

Gate valves have applications in oil and gas pipelines. Here, there is a need for isolation or complete shut-off at certain points in the system. Their ability to provide a tight seal when fully closed is valuable. They can help in situations where fluid flow must be halted entirely.

3. HVAC Systems

Check Valve

HVAC systems often require immediate response to changes in fluid flow. This is to maintain optimal temperature control. Check valves play a vital role in these systems by allowing the fluid to move in one direction. This prevents unwanted backflow and ensures efficient operation.

Gate Valve

Gate valves are not the first choice in HVAC systems. Their use can be considered in scenarios where a complete shut-off is necessary. It helps while conducting maintenance and for repair purposes.

4. Environmental Impact and Efficiency

Gate Valve

Gate valves are efficient in providing precise control. This may involve more complex control systems. The linear motion design and slower response time reduce energy consumption. It can be of great help in applications requiring frequent adjustments.

Check Valve

The simplicity and automatic operation of check valves make them energy efficient. They require minimal external control mechanisms. This reduces the overall power consumption of the system. Also, the quick response time of check valves minimizes the risk of fluid leaks. It helps prevent potential environmental hazards.

Conclusion:

The choice between a check valve and a gate valve depends on the application’s requirements. Check valves excel to prevent backflow and ensure system integrity. They help in industries such as water treatment plants. On the other hand, gate valves offer precise control over fluid flow. They are well-suited for applications where on/off control is paramount.

Ultimately, the determination of which valve is better depends on various factors. Some of them include the fluid’s nature and the required control level. It would help if you also considered the operational conditions of the system. Each valve type has its strengths and weaknesses. Appropriate selection will enhance the overall efficiency and reliability of the fluid control.