1. What To Consider When Choosing A Chinese Butterfly Valve Supplier?

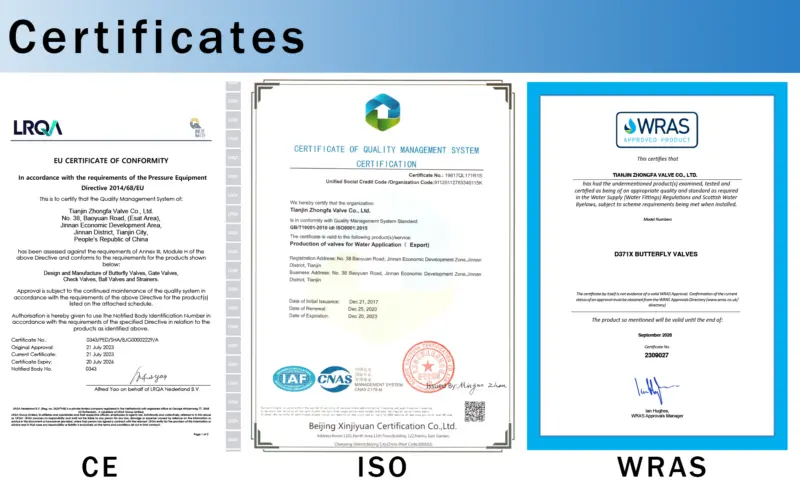

1.1. Quality and Certification

Obviously, quality is essential. Quality influences both price and usability. How to tell if a product meets international standards? The answer is that the valves manufacturer has certifications, such as ISO9001, Wras, and CE, and API, etc. These certifications validate the manufacturer’s quality and standards.

1.2. Product Range of China Butterfly Valve Supplier

Judge the types of butterfly valves the manufacturer offers. For example, some companies produce water treatment butterfly valves. Some make pure sanitary butterfly valves. Others make ventilation types.

Say from another espect, some valves manufacturer make resilient seated butterfly valve, including concentric butterfly valves and double offset butterfly valves. Others make metal seat butterfly valves like triple offset butterfly valve.

Professional products should be produced by professionals.

1.3. Industry Experience and Reputation

Choose a well-known valve manufacturer with many years of experience and good customer reviews. Such manufacturers provide more reliable products and better customer service.

1.4. After-Sales Support and Service

Butterfly valves are not disposable. So, it’s important to evaluate the after-sales support and service the manufacturer provides. Good support ensures the valve can be used effectively for a long time.

1.5. Delivery Time

A larger manufacturer doesn’t always mean shorter delivery times. Larger companies have more customers and orders. Choosing a manufacturer of the right size can ensure timely delivery. Manufacturers with global local supply chains are an exception.

1.6. Cost-Effectiveness

Cost is crucial, but it must be balanced with quality. You get what you pay for, so consider cost-effectiveness carefully.

By considering these factors, you can choose a high-quality butterfly valve manufacturer.

2. What You Need To Know About Butterfly Valves from China Butterfly Valve Supplier?

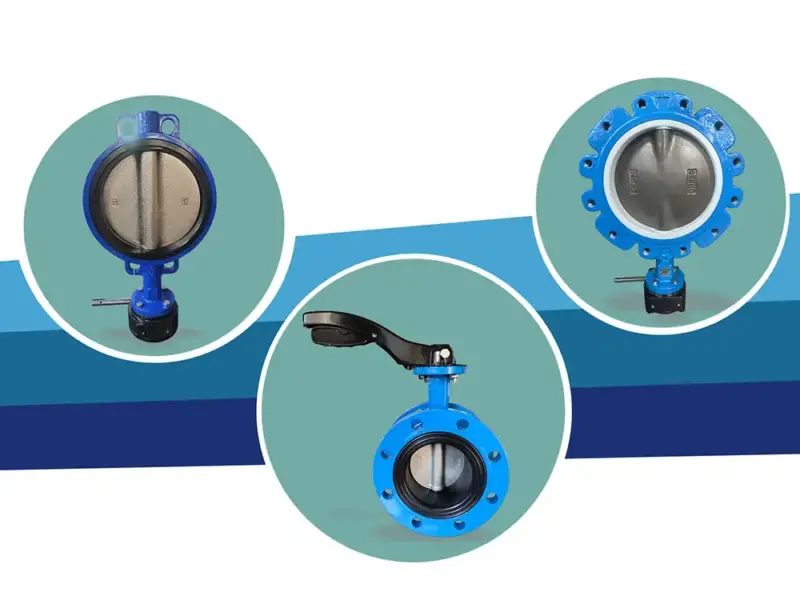

2.1. Types of Butterfly Valves

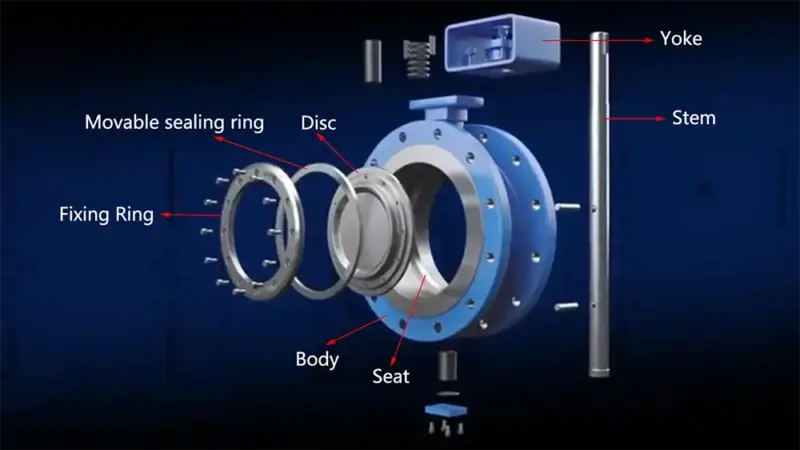

a) Resilient-Seated Butterfly Valves

These valves commonly are concentric butterfly valves, and use a rubber seat. They are providing bubble tightness sealing and suitability for low-pressure applications. Common seat materials include EPDM, Viton, and NBR. They are capable of handling different temperatures and chemical mediums.

Resilient-seated butterfly valves are ideal valves for water distribution, HVAC systems, and general industrial applications, due to their cost-effectiveness and reliability.

b) High-Performance Butterfly Valves

High performance butterfly valves also known as a type of double offset butterfly valves. This double eccentric butterfly valve design is different from the concentric butterfly valve. It is for handling higher pressures and temperatures, reduces friction between the disc and seat during operation. And it also extends the valve’s life and reliability. These valves are common in chemical processing. They are also used in oil and gas and power generation.

c) Triple-Offset Butterfly Valves

Triple-offset butterfly valves offer superior performance in demanding applications. The triple-offset design ensures zero leakage. And it can withstand very high temperatures and pressures. Triple eccentric butterfly valves are used in petrochemical, and power generation sectors.

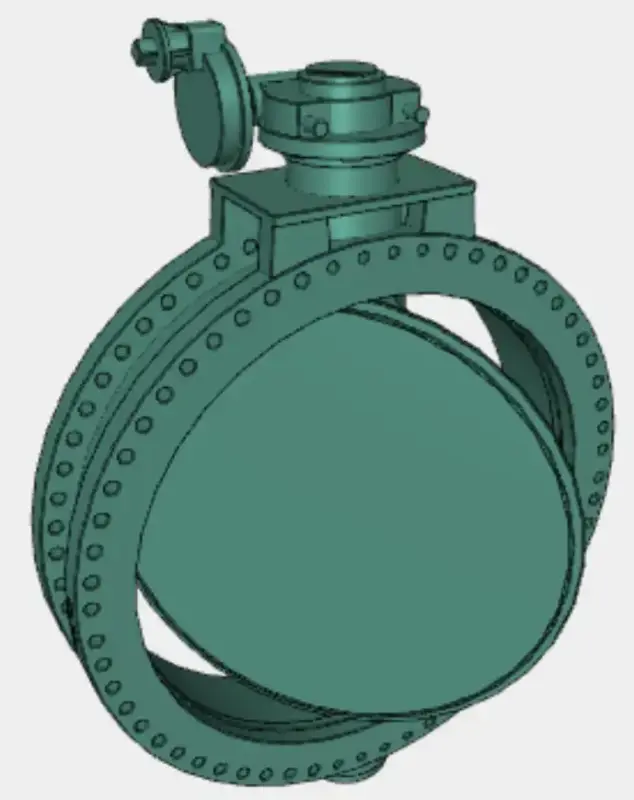

d) AWWA Butterfly Valves

AWWA Butterfly Valves are designed according to the standards set by the American Water Works Association (AWWA). AWWA valves are known for their durable construction. They can handle high flow rates and are available in sizes ranging from 3 inches to over 100 inches.

These valves are used in water systems, water treatment plants, and industrial applications.

e) API 609 Butterfly Valves

API 609 Butterfly Valves comply with the American Petroleum Institute’s (API) standard. They are resilient-seated and metal-seated butterfly valves for oil and gas industry use. These valves are designed to control in high-pressure and high-temperature environments. Designs of API 609 butterfly valve ensure bubble-tight sealing, low operating torque, and long service life. They are commonly used in petrochemical plants, refineries, and pipeline applications.

f) PTFE Fully Lined Butterfly Valves

PTFE Fully Lined Butterfly Valves are equipped with a full lining of PTFE. This king of plastic make valves highly resistant to corrosive chemicals and extreme temperatures. These valves are ideal for applications in chemical processing, pharmaceuticals, and food industries. The PTFE lining provides great non-stick properties, reducing the risk of media buildup. These valves are designed to handle a wide range of chemical mediums.

2.2. Application of Butterfly Valves

a) Water Treatment

In water treatment plants, butterfly valves can play as a shut-off valve. Because they has lighter weight and thinner FTF than gate valves, ball valves and globe valves. Besides, they provide a slight pressure drop and tight seal, ensuring no contamination. So they are suitable for potable water applications, especially the concentric butterfly valves.

b) HVAC Systems

In HVAC systems, butterfly valves control the flow of air and water, to maintain the desired temperature level. So they are used for heating, and air conditioning systems in residential and commercial buildings .

c) Oil and Gas Industry

In the oil and gas industry, three offset butterfly valves control the flow. They handle crude oil, natural gas, and refined products. Their stable design can handle high pressures and temperatures. They are suitable for upstream, midstream, and downstream applications.

d) Chemical Processing

Butterfly valves can control precise fluid flow. As the materials and design of valve can withstand aggressive chemicals and high temperatures. They ensure safe and reliable operation. ZFA high-performance butterfly valves are commonly used in these applications

e) Food Industry

Stainless steel butterfly valves or butterfly valve with wras-approved rubber seats ensure no contamination for food products.

3. China Butterfly Valve Supplier and Manufacturer

ZFA Butterfly Valve Manufacturer, a leading supplier of high-quality quarter turn butterfly valves worldwide, can provide valves that meet the stringent standards of the American/UAE/Russian/German market, etc.

Our butterfly valves are used in many industries. These include chemical processing, power generation, and water distribution.

ZFA is committed to quality. This has won praise from over 30 countries. It has established ZFA as a reliable butterfly valve supplier.

3.1 Customization in Butterfly Valves

ZFA Butterfly Valve Manufacturer has been providing customized services since 2006. The company provides customized valve solutions. These include materials, designs, etc. They cover the valve body, valve disc, and valve seat. The goal is to improve performance and durability.

3.2 Material Selection

ZFA offers butterfly valves made of stainless steel, ductile iron, WCB, and alloys. They ensure to work for corrosive chemicals, high temperatures, or abrasive media.

3.3 Global and Local Support

ZFA Butterfly Valve Manufacturer is global. It supplies valves and services to customers in over 30 countries. The company’s distribution network ensures customers receive butterfly valves quickly. It also ensures they get support on time.