Choosing between a soft-seated rising-stem gate valve and a non-rising stem gate valve involves considering several factors, including functionality, cost, maintenance, and application requirements. From an economic perspective, you’ll want to make a decision that provides the best balance between initial investment, ongoing maintenance costs, and operational efficiency. Here’s a breakdown of how to approach this decision:

1. **Application Requirements:**

Start by understanding the specific needs of your application. Consider factors such as the type of fluid or gas being controlled, the pressure and temperature conditions, flow rates, and the frequency of operation. Both types of valves have different features that make them more suitable for certain applications.

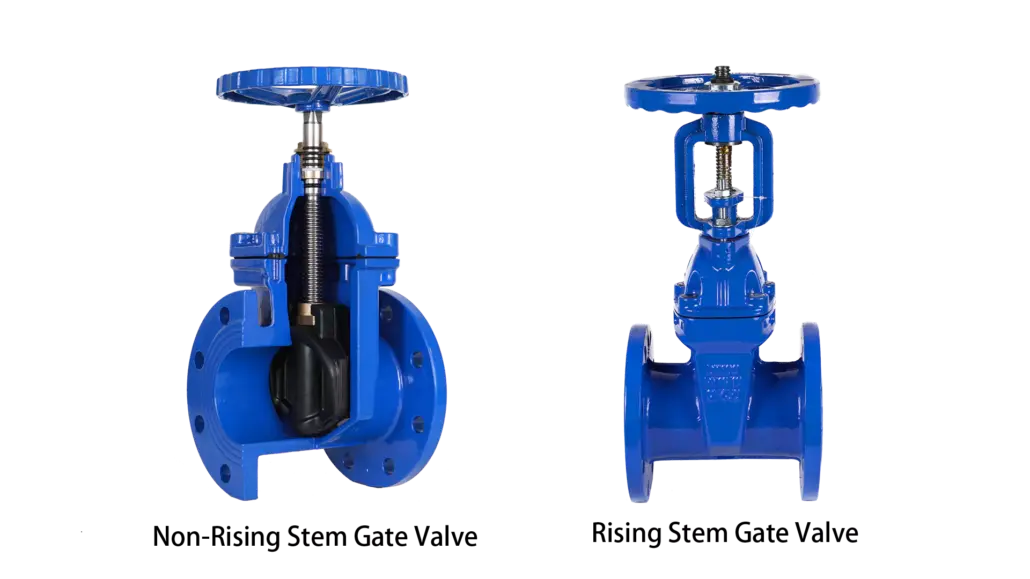

2. **Valve Types:**

– **Soft-Seated Open-Stem Gate Valve:**

– These valves are often used in applications where a tight seal is crucial, such as in water treatment plants, sewage systems, and industrial processes.

– Soft-seated valves have a resilient sealing material, such as rubber or elastomer, which provides a better seal against leakage.

– They are typically more suitable for low- to medium-pressure applications.

– Soft-seated valves might require more frequent maintenance due to the potential wear and tear of the sealing material.

– **Non-Rising Stem Gate Valve:**

– These valves are characterized by their stem design. The stem doesn’t extend above the valve body as it is turned.

– They are often used in applications where space is limited, such as underground installations or when the valve is located in a confined space.

– Non-rising stem valves are generally considered to be more robust and durable, which can lead to lower maintenance costs over time.

– They are suitable for various pressure ranges, from low to high.

3. **Cost Considerations:**

– **Initial Investment:**

– Non-rising stem gate valves might have a slightly higher initial cost due to their design and construction.

– Soft-seated gate valves might be more affordable initially, but their maintenance costs could be higher.

– **Maintenance Costs:**

– Soft-seated valves may require more frequent maintenance and replacement of the sealing material, which could increase maintenance costs over time.

– Non-rising stem valves tend to have longer lifespans and require less frequent maintenance.

4. **Operational Efficiency:**

– Consider how often the valve will need to be operated and the ease of operation for both valve types.

– Non-rising stem valves are often easier to operate, especially in confined spaces where the length of the stem matters.

5. **Long-Term Considerations:**

– Evaluate the expected lifecycle of the valve and factor in replacement costs.

– Consider the cost of downtime in case of valve failure or maintenance activities.

6. **Environmental and Safety Factors:**

– If your application involves hazardous materials or requires strict environmental regulations, one valve type might be more suitable.

In conclusion, the choice between a soft-seated open-stem gate valve and a non-rising stem gate valve from an economic perspective depends on the specific requirements of your application, considering factors like initial cost, maintenance cost, operational efficiency, and long-term durability. It’s advisable to consult with valve experts or engineers who can provide a tailored recommendation based on your specific needs and circumstances.