we will discuss the key factors of butterfly valve quality from the aspects of weight, material, rubber, spray coating, etc.

With the continuous development of the market, customers have different demands for the quality requirements of valves. Zhongfa Valve is committed to providing customers with high-quality valves. So, what kind of valves are high-quality valves? What conditions do valves meet to be considered good quality valves?

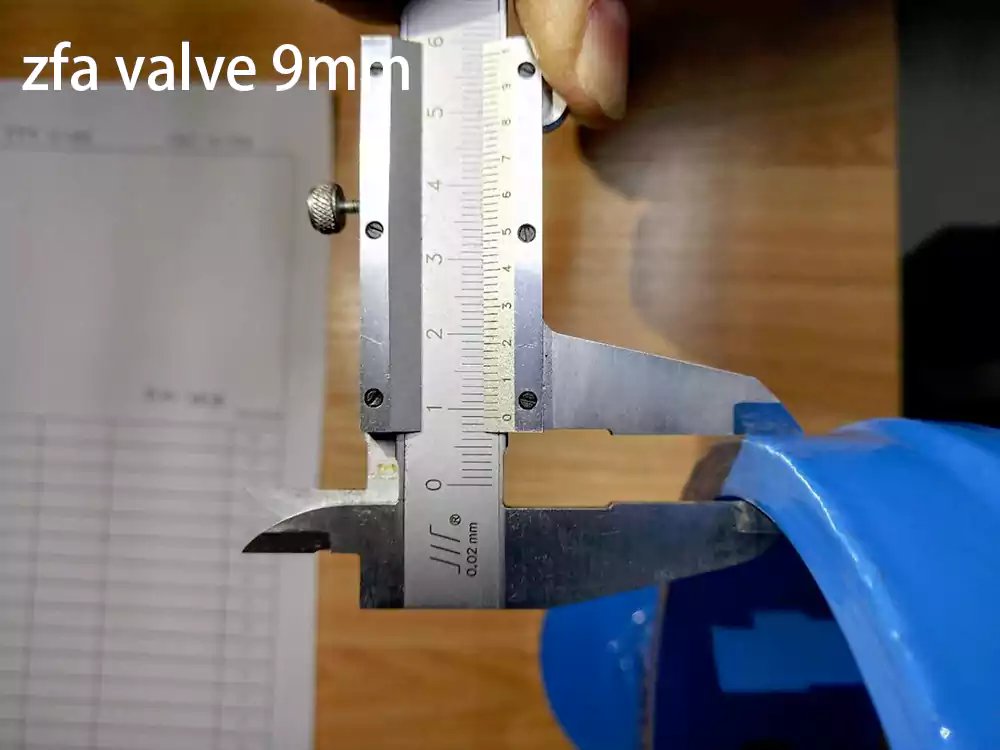

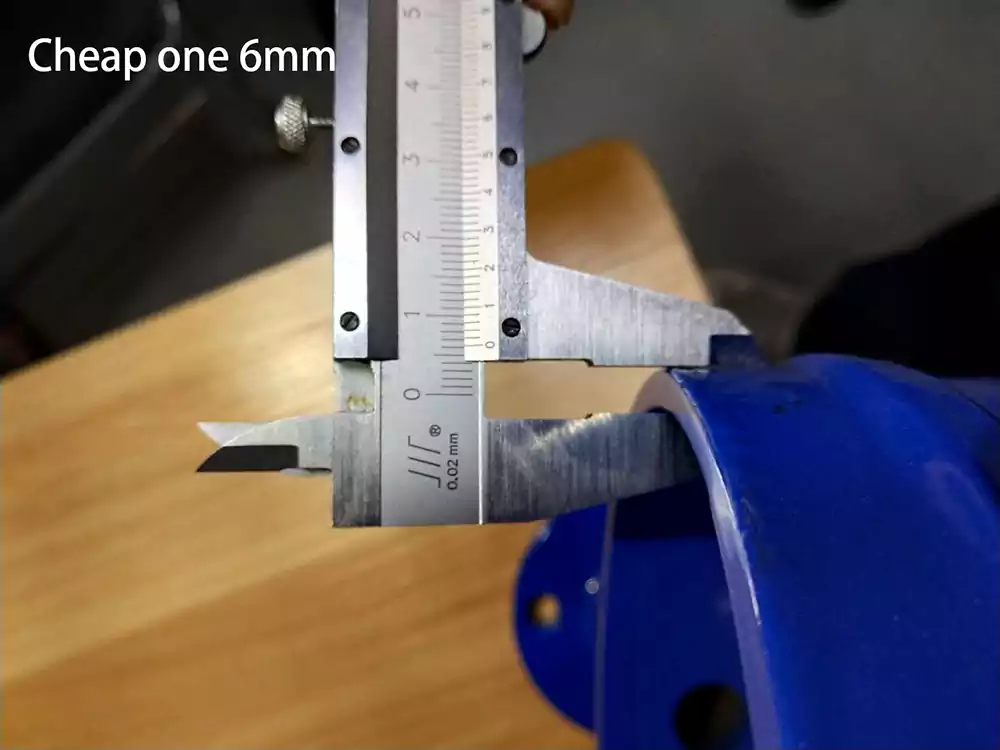

1. Valve Weigh and Body Thickness Is the Most Significant Factor of Butterfly Valve Quality

A high-quality valve must have sufficient weight, and the valve body thickness and flange thickness must reach a certain value. Only when the valve body thickness and flange thickness reach a certain value can it withstand the pressure. The material cost directly affects the price and cost. The simplest test method is to look at the weight. The weight of the valve largely reflects the quality of the valve;

2.The component elements of the material is also Key Factors of Butterfly Valve Quality

-

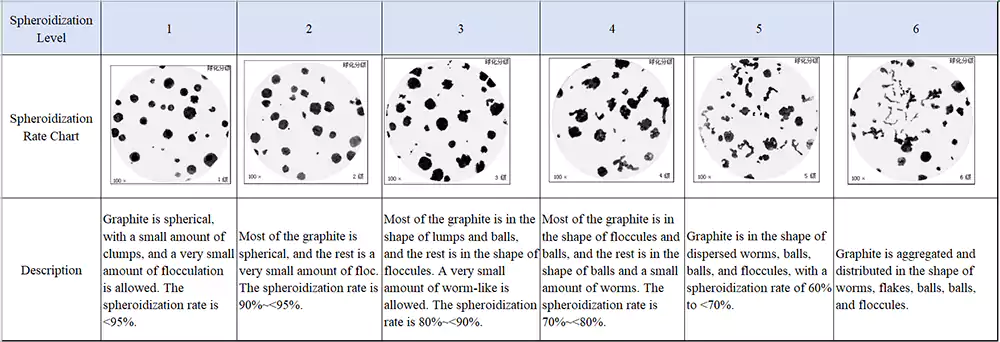

Ductile iron butterfly valve

For ductile iron butterfly valves, the spheroidization rate is a very critical factor. The so-called spheroidization rate refers to the comprehensive index of the spheroidization degree of all graphite within a specified field of view. It reflects the degree to which all graphite within the field of view is nearly spherical. The national standard classifies ductile iron graphite spheroidization into grades 1-6 based on graphite morphology, distribution and spheroidization rate. The mechanical properties of ductile iron are largely determined by the nodularity rate. Generally speaking, when other conditions are the same, the higher the spheroidization rate, the higher the mechanical properties.

-

carbon steel butterfly valves

carbon steel is an iron-carbon alloy with a carbon content of 0.0218%~2.11%. Generally also contains small amounts of silicon, manganese, sulfur, and phosphorus. In general, the higher the carbon content of carbon steel, the higher the hardness and strength, but the lower the plasticity. It is used on metal parts that require strength, hardness and wear resistance, such as cutting tools, steel cables, piano wires, springs and knives.

After processing, the parts usually need to be processed and tempered. The higher the carbon content of the steel, the higher its hardness, strength and wear resistance after heat treatment. Carbon steel is divided into high carbon steel, medium carbon steel and low carbon steel. These three types of carbon steel are divided into two types. According to their characteristics, high carbon steel is hard and brittle, while low carbon steel is soft and resistant to ductility.

Classification:

(1) According to the use, carbon steel can be divided into three categories: carbon structural steel, carbon tool steel and free-cutting structural steel. Carbon structural steel is further divided into two types: engineering construction steel and machine-made structural steel;

(2) According to the smelting method, it can be divided into open hearth steel and converter steel;

(3) According to the deoxidation method, it can be divided into boiling steel (F), killed steel (Z), semi-killed steel (b) and special killed steel (TZ);

(4) According to the carbon content, carbon steel can be divided into low carbon steel (WC ≤ 0.25%), medium carbon steel (WC 0.25%-0.6%) and high carbon steel (WC ≥ 0.6%);

(5) According to the quality of the steel, carbon steel can be divided into ordinary carbon steel (higher phosphorus and sulfur content), high-quality carbon steel (lower phosphorus and sulfur content) and high-grade high-quality steel (lower phosphorus and sulfur content). ) and special grade high quality steel

-

Stainless steel butterfly valve

The key reason why stainless steel is stainless is that it contains chromium. The required minimum chromium content is stipulated in American and European standards as no less than 10.5% (mass fraction, the same below). The Japanese industrial standard stipulates that it is generally no less than about 11%. In my country, it is generally considered to be no less than 12%. Stainless steel is divided into five major categories: austenitic stainless steel, ferritic stainless steel, martensitic stainless steel, austenitic-ferritic duplex stainless steel and precipitation hardening stainless steel.

How to check the quality of stainless steel butterfly valve?

You can use a spectrometer to directly measure the material composition of stainless steel to see if the material meets the standards;

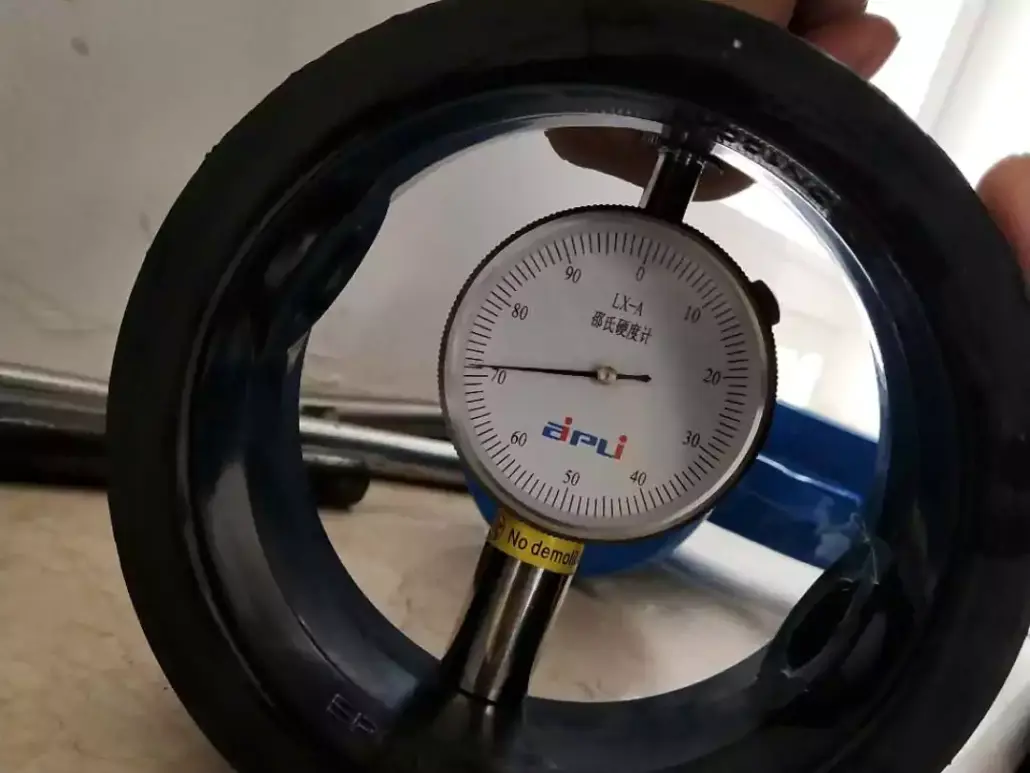

3. The Quality of Rubber Seat Determine The Quality Of Soft Seal Butterfly Valves

The quality of the butterfly valve seat rubber are affected by the following factors:

(1)The content of natural rubber directly determines the quality of rubber

(2)Ratio of rubber content and carbon black

(3)Vulcanization time and temperature and whether the factory’s vulcanization technology is mature also affect the quality of rubber.

(4)Some factories will use recycled rubber to make valve seats, which will greatly reduce the quality of the valve seats.

How to check the quality of rubber

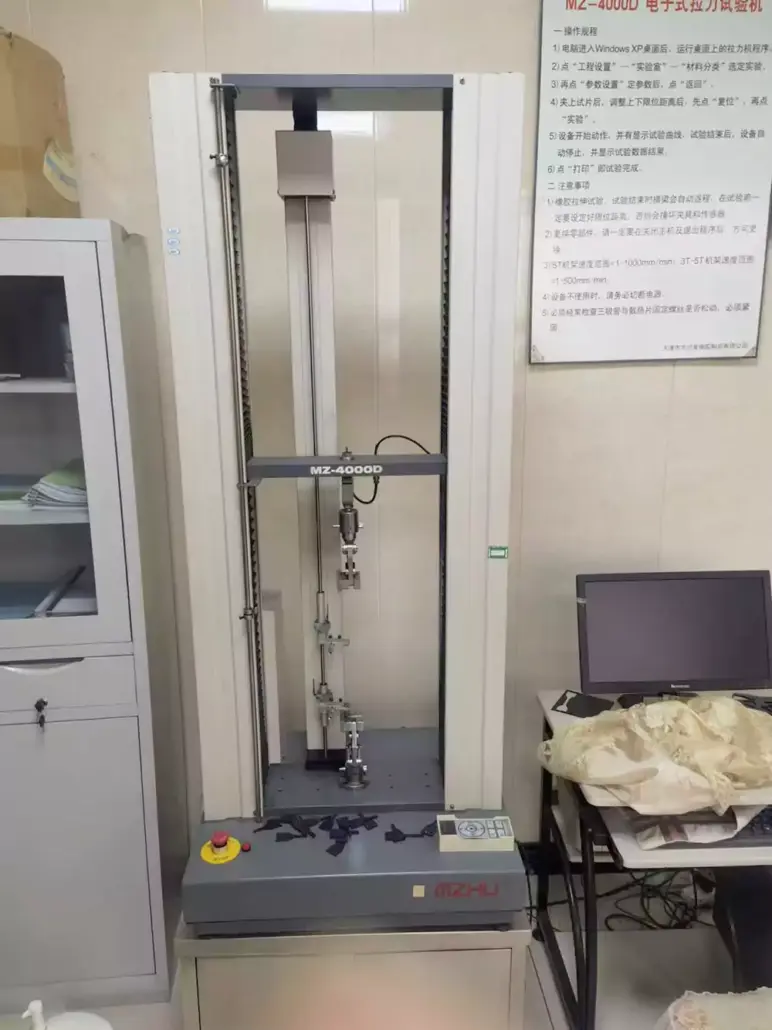

(1)Rubber strength test and pull-up test;

(2)Aging and compression test;

Rubber strength test

Rubber aging test

4. the spraying process of butterfly valves.

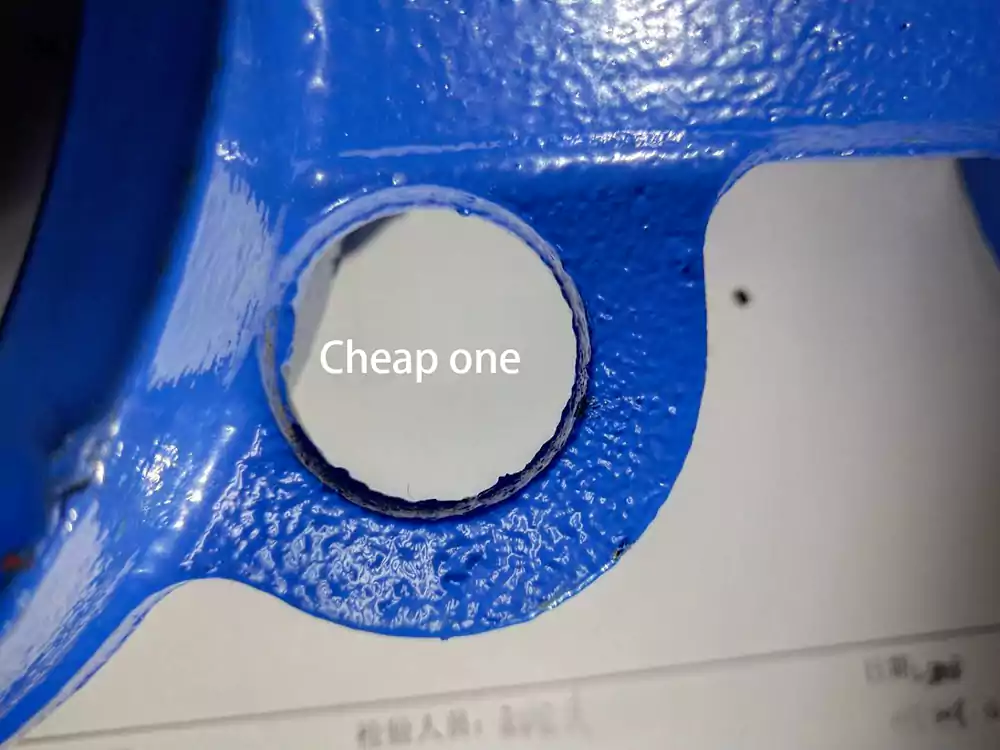

The quality of butterfly valve spraying is affected by the following factors:

How to check whether spraying is up to standard?

Therefore, every high-quality butterfly valve shipped from Zhongfa Valve needs to undergo complex processing and quality control at all levels. Zhongfa valve is your trustworthy choice.