What Is a Gate Valve?

The gate valve is a valve with a gate inside that opens and closes. The movement direction of the gate is perpendicular to the direction of the fluid. Gate valves can only be fully opened and closed, so they cannot be adjusted to the medium. Following, we will explain the rising stem VS non rising stem gate valve.

What Is a Rising Stem Gate Valve?

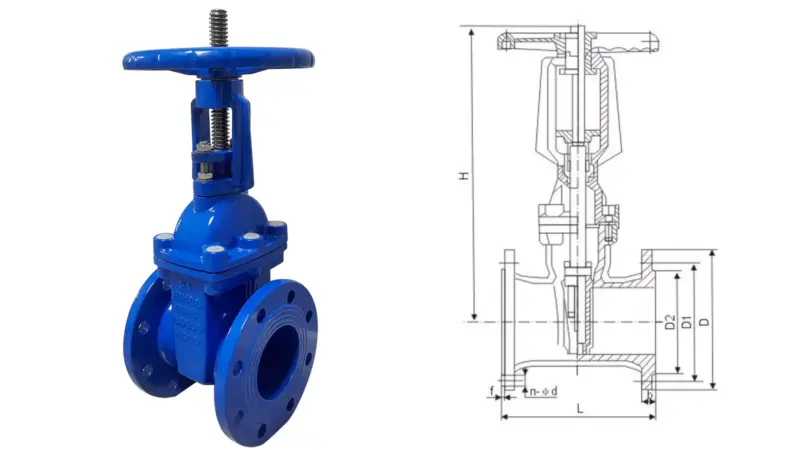

When the lift height of the gate plate is equal to 1:1 times the valve diameter if the valve is opened, the fluid channel is entirely unobstructed. However, during operation, this position cannot be monitored. The top of the valve stem is used as a mark, that is, the position that does not open, as it is a fully open position. To consider the locking phenomenon caused by temperature changes, the valve is usually opened to the top position and then retracted 1/2 to 1 turn as the fully open valve position. Therefore, the valve’s fully open position is determined by the position of the gate (i.e. stroke).

Advantages of os&y gate valve:

- The fluid resistance is small, and the sealing surface is less eroded and eroded by the medium.

- Opening and closing require less effort.

- The flow direction of the medium is not restricted, and there is no flow disturbance or pressure reduction.

- It has a simple shape, short structural length, good manufacturing process, and wide application range.

Disadvantages of os&y gate valve:

- Erosion and scratches can easily occur between the sealing surfaces, making maintenance difficult.

- The overall size is large, requires a certain amount of space, and takes a long time to open and close.

- The structure is complex.

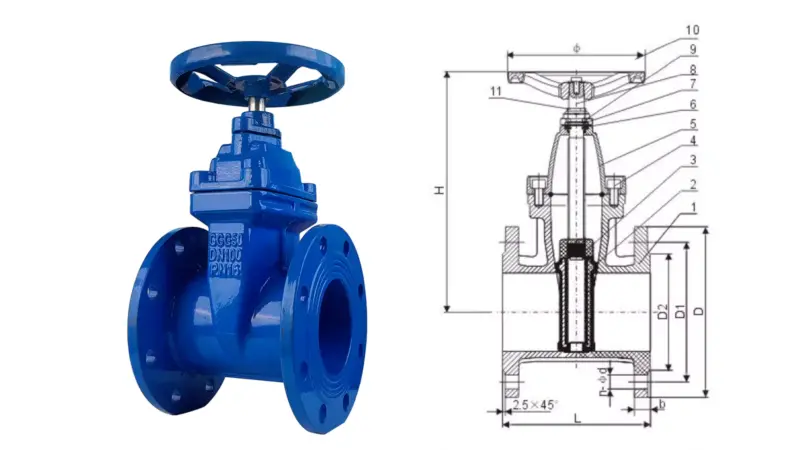

What Is a Non Rising Stem Gate Valve?

A non-rising stem gate valve is also called a rotating stem gate valve (also called a non-rising stem wedge gate valve). The valve stem nut is set on the gate plate. The rotation of the handwheel drives the valve stem to rotate, which lifts the gate plate. There is usually a trapezoidal thread at the bottom of the valve stem. The rotating movement is carried out through the thread at the bottom of the valve and the guide groove on the valve disc. It changes into linear motion; the operating torque is changed into operating thrust.

Advantage of non-rising stem gate valve:

The height of the gate valve always remains unchanged, so the installation space is small. This structure is suitable for gate valves with large diameters or limited installation space. It should be equipped with an opening and closing indicator to indicate the degree of opening and closing.

Disadvantage of non-rising stem gate valve:

The valve stem thread is not only unable to be lubricated but also directly eroded by the medium and easily damaged.

Rising Stem VS Non Rising Stem Gate Valve

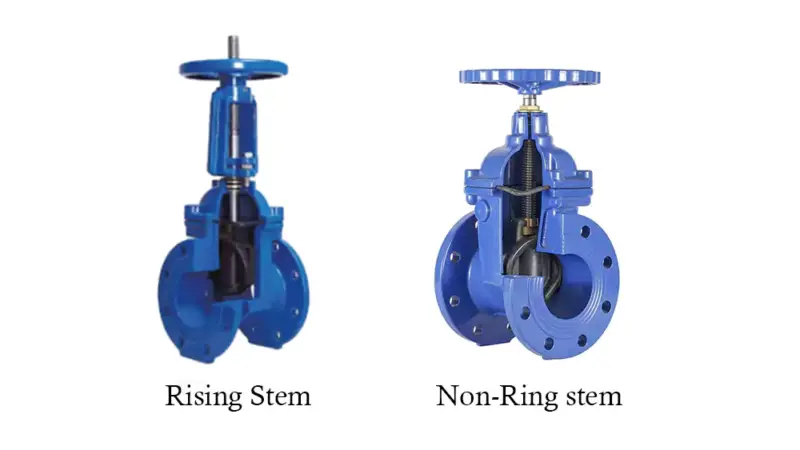

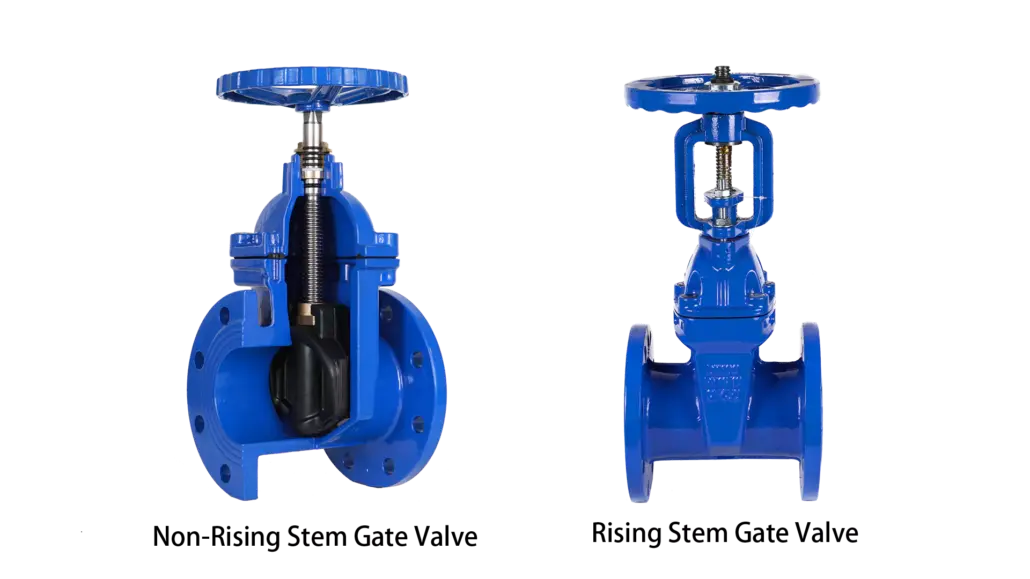

- The spindle cannot be seen in non-rising stem valves, while it can be seen in rising stem valves.

- The lifting stem of the non-rising stem valves only rotates without moving up and down; only a rod is exposed. Its nut is fixed on the gate plate. The spindle rotation lifts the gate plate, and there is no visible door-shaped frame. The lifting stem of the rising stem gate valve is exposed, and the nut is close to the handwheel and is fixed (does not rotate or move axially). The gate is lifted by rotating the stem. The stem and the gate only have relative rotational movement. There is no relative axial displacement, and the appearance is a door-shape frame.

- The handwheel and the valve stem of the non-rising stem valve are connected together and are relatively immobile when opening and closing. It opens and closes by rotating the valve stem at a fixed point to drive the valve disc upward and lower the gate. The rising stem valve uses threaded transmission between the valve stem and the handwheel to lift or lower the disc. Simply put, in a rising stem valve, the valve disc moves up and down together with the valve stem. The handwheel is always at a fixed position.

Choosing A Rising Stem Or Non Rising Stem Gate Valve (Soft-seated)

Choosing between a soft-seated rising stem gate valve and a non-rising stem gate valve involves considering several factors. These include functionality, cost, maintenance, and application requirements. From an economic perspective, you’ll want to decide to provide the best balance between initial investment, ongoing maintenance costs, and operational efficiency. Here’s a breakdown of how to approach this decision:

1. Application Requirements:

Start by understanding the specific needs of your application. Consider factors such as the type of fluid or gas being controlled, the pressure and temperature conditions, flow rates, and the frequency of operation. Both types of valves have different features that make them more suitable for certain applications.

2. Valve Types:

Soft-Seated Rising Stem Gate Valve:

– These valves are often used in applications where a tight seal is crucial, such as in water treatment plants, sewage systems, and industrial processes.

– Soft-seated valves have a resilient sealing material, such as rubber or elastomer, which provides a better seal against leakage.

– They are typically more suitable for low- to medium-pressure applications.

– Soft-seated valves might require more frequent maintenance due to the potential wear and tear of the sealing material.

Non-Rising Stem Gate Valve:

– These valves are characterized by their stem design. The stem doesn’t extend above the valve body as it is turned.

– They are often used in applications where space is limited, such as underground installations or when the valve is located in a confined space.

– Non-rising stem valves are generally considered to be more robust and durable, which can lead to lower maintenance costs over time.

– They are suitable for various pressure ranges, from low to high.

3. Cost Considerations:

Initial Investment:

– Non-rising stem gate valves might have a slightly higher initial cost due to their design and construction.

– Soft-seated gate valves might be more affordable initially, but their maintenance costs could be higher.

Maintenance Costs:

– Soft-seated valves may require more frequent maintenance and replacement of the sealing material, which could increase maintenance costs over time.

– Non-rising stem valves tend to have longer lifespans and require less frequent maintenance.

4. Operational Efficiency:

– Consider how often the valve will need to be operated and the ease of operation for both valve types.

– Non-rising stem valves are often easier to operate, especially in confined spaces where the length of the stem matters.

5. Long-Term Considerations:

– Evaluate the expected lifecycle of the valve and factor in replacement costs.

– Consider the cost of downtime in case of valve failure or maintenance activities.

6. Environmental and Safety Factors:

– If your application involves hazardous materials or requires strict environmental regulations, one valve type might be more suitable.

In conclusion, the choice between a soft-seated rising stem gate valve and a non-rising stem gate valve from an economic perspective depends on the specific requirements of your application, considering factors like initial cost, maintenance cost, operational efficiency, and long-term durability. It’s advisable to consult with valve experts or engineers who can provide a tailored recommendation based on your specific needs and circumstances.