Introduction

Butterfly valves are essential components in fluid control systems, used to regulate the flow of various liquids and gases. They come in different designs, each catering to specific application needs. Two common variants are steel welded butterfly valves and cast butterfly valves. While both serve the same fundamental purpose, they differ significantly in terms of construction, performance, and suitability for various applications. In this article, we will delve into the key differences between these two types of butterfly valves.

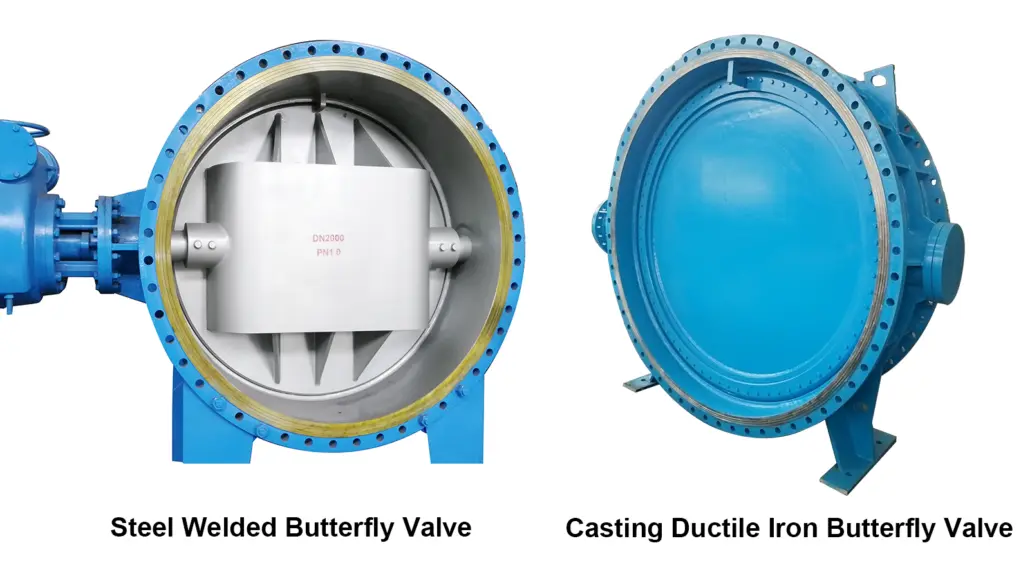

Differences Between Steel Welded Butterfly Valves and Cast Butterfly Valves

Construction Materials

Steel Welded Butterfly Valve: The steel welded butterfly valve is manufactured by a series of methods such as steel plate roll, laser cutting, and then parts welding. The commonly used materials are Q235, Q345,Q234, stainless steel.

Cast Butterfly Valve: Cast butterfly valves are made through the casting process, wherein molten metal is poured into a mold to create the valve’s shape. The commonly used materials cast iron, ductile iron, or stainless steel.

Manufacturing Process

Cast Butterfly Valve: Casting allows for greater flexibility in design but might result in slight imperfections due to the molding process. While cast valves are generally robust, they might not be as suitable for extremely high-pressure applications as welded steel valves. Casting butterfly valves have good rigidity and are not easily deformed after bearing pressure, but the cost is high, the construction period is long, and casting defects are inevitable, such as blisters.

Steel Welded Butterfly Valve: Welded steel butterfly valves are renowned for their exceptional strength and durability. The welding process eliminates potential weak points in the valve’s structure, making them suitable for industrial applications that involve high-pressure and high-temp. The steel welded butterfly valve is easy to manufacture, but due to the good toughness and variability of the steel plate itself, its rigidity is poor, and the elastic deformation after pressure will affect the sealing performance. In addition, the wear resistance is poor, and the service life is not as good as that of the cast butterfly valve. The welded butterfly valve has low cost, beautiful appearance and no casting defects.

the market demand point of view

the market demand for casting butterfly valve is higher than the steel plate welded butterfly valve, usually for small diameter butterfly valve, basically with casting, for large diameter butterfly valve, when the customer takes into account the cost savings, may choose to weld the butterfly valve steel plate. Welded steel plate butterfly valve, more test of a welder’s skill level, the quality of the valve, by the welder’s skill level of the impact is relatively large, more uncontrollable. Casting butterfly valve, belongs to a more mature technology, casting level is more stable, warmly welcomed by the market.