Valves play an important role in fluid control. Butterfly valves are among the most used valves today. When it comes to fluid control systems, these valves are used for better operation. They help enhance performance and keep things in check. Of all the different valve choices, wafer and flanged valves are popular. The purpose of both these valves is similar. However, the difference comes when we discuss their features and qualities. When you know these qualities, you can make the right decision. So, let us understand and discuss wafer VS flanged butterfly valves in detail.

Before we proceed, we must know the basics. So, what is a butterfly valve? Well, these are among the most popular types. Do you know that these are also called quarter-turn valves? Yes! With a circular disc present in the center, they work on a diametrical axis. A quarter-turn of the valve handle or actuator turns the disc from fully closed to open or vice versa. This simple and efficient operation makes them popular in various industries for controlling pipeline flow.

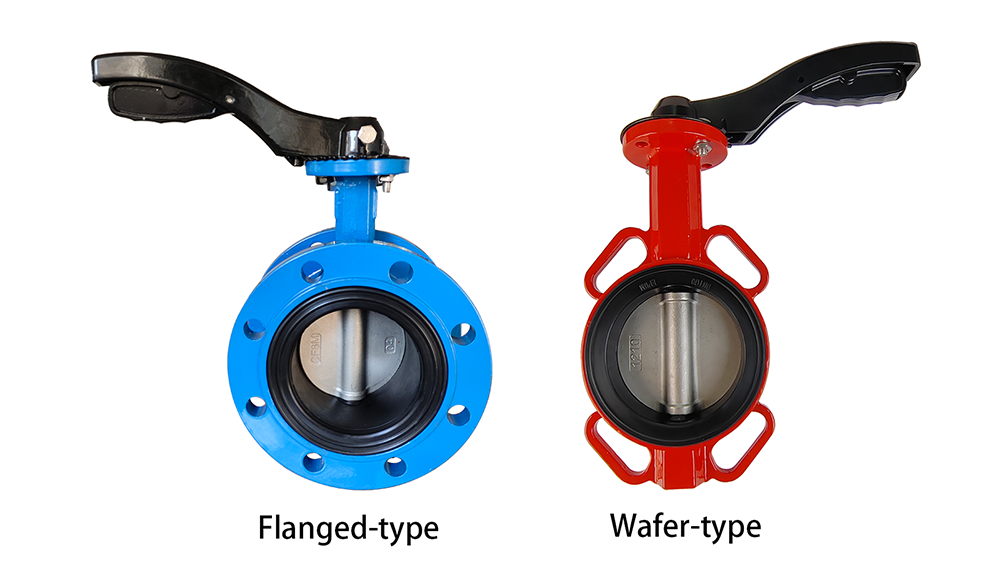

Butterfly valves have a wide range of applications. They are widely used in general industries such as petroleum, natural gas, chemicals, and water treatment. Butterfly valves have two connection methods: wafer type and flange type. In the following sections, we will discuss each type.

What Is A Wafer Butterfly Valve?

A wafer-style butterfly valve is simple and convenient. It is compact and lightweight, so the installation process is very convenient. Also, the valve has a simple design with a disc in it. The central shaft can rotate inside the valve. One factor that makes them different is a no-bolt-hole body. Yes! The wafer butterfly valves rather depend on the pressure of the mating flanges to stay in place.

In the following section, we will talk about some advantages of a wafer-type butterfly valve.

The Advantages Of A Wafer Type Butterfly Valve

Let us discuss the advantages of wafer butterfly valves so that you can get a better idea of them.

-

Space-Saving Design

Wafer butterfly valves offer a space-saving design. Yes! These valves are thinner than the flanged butterfly valve. Thus, one can use them in places with limited space. Also, you can use them where you need to consider weight limitations.

-

Easy To Install

We all know that installation plays a crucial role when talking about valves. Thus, another advantage of wafer butterfly valves is their ease of installation. Installing these valves is simple and smooth, and no tool is needed.

-

Low-Pressure Drop

One of the most amazing advantages of these valves is the low-pressure drop. The design ensures minimal pressure drops and smooth flow.

-

Cost Cutting

We aim to get the best results at a low investment in any installation or management process. In that case, choosing a wafer-style butterfly valve is the best decision that you can take. It has a simple design and a basic construction. Thus, the reduced material need makes this a cost-effective solution.

-

Dynamic Use

Why do so many people prefer a wafer-style butterfly valve? This is because these valves are versatile. You can use them in different places of your choice. These industries are water treatment, HVAC, and chemical processing.

Thus, these are all the advantages of a wafer-style butterfly valve. Now that we know about these let us discuss the other one – the flange butterfly valve.

What Is A Flanged Butterfly Valve?

Let’s discuss flanged butterfly valves in detail. Flanged butterfly valves have bolt holes around their bodies. What is the advantage of having these holes? Well, with these holes, it becomes easier to attach them to each end of the pipes. Thus, the connection that these valves provide is robust and stable. So, where high pressure and large size are present, a flanged butterfly valve is present.

Other than this, are there any advantages to these valves? We will discuss these advantages in the following section.

The Advantages Of A Flanged Butterfly Valve

Many people want to learn about the advantages of these valves. So, let us discuss the advantages of these valves in detail.

-

Stable Connection

One of the primary reasons you will see these valves in use is their stability. Yes! These valves are secure. They offer amazing stability and resistance to pipe vibrations. Also, you will not see any leaks through them. Thus, fantastic stability and security are why people choose these valves.

-

Dealing With High Pressure

Do you know that a flanged butterfly valve can deal well with high pressure? Yes! These valves can handle high-pressure well. The design of these valves is such that even in high pressure, they can deliver well.

-

Wide Range Of Sizes

Another critical aspect of these valves is the wide range of sizes available. These flanged butterfly valves come in different sizes that make them versatile. We see their use in power generation, oil and gas, etc.

Wafer VS Flanged Butterfly Valve: How To Choose The Right Valve For Your Use

Now, we have learned in detail about wafer vs. flanged butterfly valves. But the main point is not wafer and flanged butterfly valves. It is finding the most effective valve for our use. So, how do you choose the right valve? What factors do you need to consider? We will discuss them in detail here.

-

Operating Pressure and Temperature

The primary factor to consider is the operating pressure and temperature at which the valve works.

Wafer valve bolts are generally relatively long. Under high-temperature conditions, the expansion of the bolts may cause leakage. So, they are not suitable for large-diameter pipes under high-temperature conditions. Hence, choose a flanged butterfly valve if there is high temperature and pressure. You will choose the other one if the pressure and temperature are low.

-

Budget

When choosing the correct valve, consider the budget demands. Make sure you know the money involved.

Integral flanges require additional materials and processing, so flange butterfly valves are more expensive. In comparison, wafer butterfly valves are more cost-effective. They require less material to install and are easier to manufacture. With wafer butterfly valves, we get an initial cost-cutting. However, in the long term, the flanged butterfly valves will provide durability.

-

Consideration of Space

Everyone’s use of valves will be different. Thus, consider the amount of space you have before choosing the valve.

Flanged butterfly valves are larger and heavier because of the integral flanges on both ends. In comparison, wafer butterfly valves are more compact and lighter. You can go with the wafer butterfly valve if you have a compact space. If you have enough space, you can go for the other type of valve for your construction.

-

Installation and Maintenance

Some people are not aware of the installation process, which later creates problems for them. Thus, you should know the installation need when choosing a valve.

The wafer butterfly valve does not have integral flanges at both ends. Instead, the valve is connected to the flanges at both ends with bolts or nuts. This means it requires less space for installation and is easier to disassemble and repair.

Flanged butterfly valves have integral flanges on both ends. This require additional space and more effort to disassemble and repair. The reason is that they require the removal of bolts or studs from the integral flange.

-

Industry Regulation And Company

One of the things that you should always consider is the brand. Maintaining industry standards in manufacturing and production is prime. Hence, choosing a reputed brand that delivers top-notch industry-standard valves is important.

As an industrial valve manufacturer in China, ZFA Valve specializes in producing soft and hard seal wafer and flange butterfly valves. We have 10+ years of experience and a professional sales and technical team. So, we are here to provide service if you have any questions.

Conclusion

This concludes our discussion of wafer vs flanged butterfly valve. Each of these valves has different roles and advantages. Also, with different features, both of the valves help us. But who to choose is your decision.

It would help if you considered every factor associated with them. This is how you will benefit in the long run. Also, consider choosing a brand that follows industry regulations. It ensures you get the best valves. So, consider all these points so that you go with the valve that suits your needs.