The AWWA C504 butterfly valve is a special type of valve used in water distribution systems. It is designed to meet the standards set by the American Water Works Association (AWWA) and is commonly used in municipal water treatment plants, distribution systems and other industries for water treatment, plumbing, industrial fluids, etc. The valve is known for its reliable performance, ease of operation and durability.

1.AWWA C504 butterfly valves materials:

AWWA C504 butterfly valves are typically made of wear-resistant materials:

Valve body: High strength ductile iron(ASTM A536, A395), carbon steel(A108), WCB(A216) or stainless steel(304, 316).

Valve disc: stainless steel, duplex steel, ductile iron, bronze etc.

Valve seat: rubber and other elastic sealing materials (EPDM, NBR, silicone rubber, FPM).

Valve stem: forged stainless steel, 1.4462, monel etc.

2. AWWA C504 STD about butterfly valve pressure

– 75LB (75 psi)

– 150LB (150 psi)

– 250LB (250 psi)

3. What does the specification Awwa c504 specify?

3.1. FACE TO FACE

| FTF for flanged and wafer valves | |||||||

| Valve Size | Short Body | Long Body | Wafer | ||||

| in. | (mm) | in. | (mm) | in. | (mm) | in. | (mm) |

| 3 | (75) | 5 | (127) | 5 | (127) | 2 | (50.8) |

| 4 | (100) | 5 | (127) | 7 | (178) | 2½ | (57.2) |

| 6 | (150) | 5 | (127) | 8 | (203) | 2 | (71.4) |

| 8 | (200) | 6 | (152) | 8½ | (216) | 2 | (74.6) |

| 10 | (250) | 8 | (203) | 15 | (381) | 3½ | (79.4) |

| 12 | (300) | 8 | (203) | 15 | (381) | 3 | (85.7) |

| 14 | (350) | 8 | (203) | 16 | (406) | 3 | (96.3) |

| 16 | (400) | 8 | (203) | 16 | (406) | 4 | (105.0) |

| 18 | (450) | 8 | (203) | 16 | (406) | 45/8 | (117.0) |

| 20 | (500) | 8 | (203) | 18 | (457) | 5 | (130.0) |

| 24 | (600) | 8 | (203) | 18 | (457) | ||

| 30 | (750) | 12 | (305) | 22 | (559) | ||

| 36 | (900) | 12 | (305) | 22 | (559) | ||

| 42 | (1,050) | 12 | (305) | 24 | (610) | ||

| 48 | (1,200) | 15 | (381) | 26 | (660) | ||

| 54 | (1,350) | 15 | (381) | 28 | (711) | ||

| 60 | (1,500) | 15 | (381) | 30 | (762) | ||

| 66 | (1,650) | 18 | (457) | 34 | (864) | ||

| 72 | (1,800) | 18 | (457) | 36 | (914) | ||

3.2. Disc Material & Style:

When the valve disc is under pressure, it shall not exceed 1/5 of the material tensile strength.

3.3. Inspection and Testing:

3.1. Repeatedly open and close at least 3 times to ensure smooth switching.

3.2. During the leak test, there should be no evidence of leakage through the valve plate

3.3. After testing, there are no worn areas (valve body, disc, shaft or pin) that could affect valve performance.

4. The classification of Awwa c504 butterfly valve

4.1.According to connection type, Awwa c504 butterfly valve can be divided into

- Wafer butterfly valve

- Flange butterfly valve

- Lug butterfly valve

4.2. According to the valve plate structure, Awwa c504 butterfly valve can be divided into

4.2.1. Center line awwa c504 butterfly valve

4.2.2. AWWA C504 Eccentric butterfly valve

- Double eccentric awwa c504 butterfly valve

- Triple offset butterfly valve

5. Structural length difference between AWWA C504 and EN558.

AWWA C504 is formulated by the American Water Works Association (AWWA), and the EN 558 standard is formulated by the European Committee for Standardization (CEN).

The AWWA C504 standard mainly regulates the use of butterfly valves in water supply and sewage systems, while the EN558 standard is more broadly applicable to different types of butterfly valves, gate valves, etc.

| NPS | DN | L(S13) | L(S14) | C504 |

| 14” | 350 | 190 | 290 | 203 |

| 16” | 400 | 216 | 310 | 203 |

| 18” | 450 | 222 | 330 | 203 |

| 20〞 | 500 | 229 | 350 | 203 |

| 24〞 | 600 | 267 | 390 | 203 |

| 28” | 700 | 292 | 430 | 305 |

| 30〞 | 750 | 292 | 430 | 305 |

| 32” | 800 | 318 | 470 | 305 |

| 36” | 900 | 330 | 510 | 305 |

| 40” | 1000 | 410 | 550 | 305 |

| 42” | 1050 | 410 | 550 | 305 |

| 48” | 1200 | 470 | 630 | 381 |

| 54” | 1350 | 530 | 710 | 381 |

| 56” | 1400 | 530 | 710 | 381 |

| 60” | 1500 | 530 | 710 | 381 |

| 64” | 1600 | 600 | 790 | 457 |

| 66” | 1650 | 600 | 790 | 457 |

| 72” | 1800 | 670 | 870 | 457 |

6. Applications of AWWA C504 Butterfly Valves

6.1 Water Systems

One of the main applications of AWWA C504 butterfly valves is in municipal water systems. They are used to control and regulate the flow of water in pipes, ensuring efficient distribution and management of water resources.

6.2 Wastewater Treatment Plants

These valves are also essential in wastewater treatment plants. They help control the flow of wastewater through various treatment processes, ensuring that the water is effectively treated before being discharged back into the environment.

6.3 Industrial Applications

In addition to municipal applications, AWWA C504 butterfly valves are also used in various industrial processes. They are particularly useful in industries that need to control and regulate large amounts of fluids, such as chemical processing, food and beverage production, and power generation.

6.4 Irrigation Systems

AWWA C504 butterfly valves are also used in agricultural irrigation systems. They help manage the flow of water to different areas of farmland, ensuring that crops receive the amount of water they need to grow optimally.

7. Advantages of AWWA C504 Butterfly Valve

7.1 Durability and service life

Durability is one of the significant advantages of the AWWA C504 butterfly valve. Because the use of high-quality materials ensures that the butterfly valve can withstand harsh operating conditions. and provide a long service life while minimizing maintenance requirements.

7.2 Efficient flow control

These butterfly valves provide precise flow control, allowing operators to accurately regulate the flow of water or other fluids. This is particularly important in applications where maintaining a specific flow rate is critical to process success.

7.3 Cost-effectiveness

The AWWA C504 butterfly valve is relatively cost-effective compared to other types of valves such as gate valves or ball valves. Its simple design and ease of installation help reduce overall costs, making it ideal for many applications.

7.4 Easy to maintain

The AWWA C504 butterfly valve is designed for easy maintenance. The valve can be inspected and serviced without complete disassembly, reducing downtime and maintenance costs.

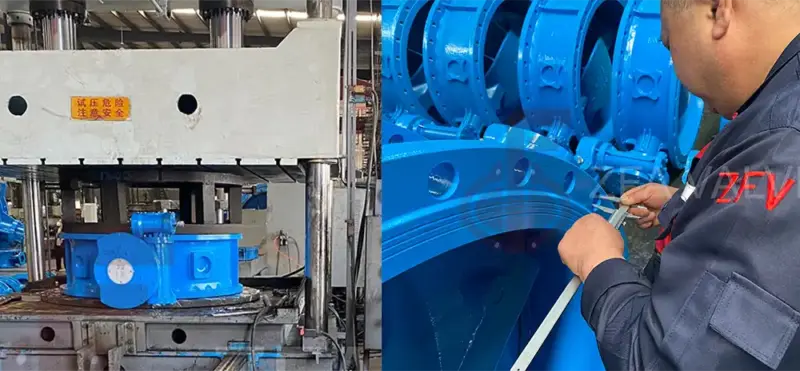

8. Awwa C504 Butterfly Valve Manufacturer

Not all butterfly valve manufacturers can produce AWWA C504 butterfly valves, but zfa valve is one of the few manufacturers in China that can produce this type of butterfly valve. As zfa started producing butterfly valves in 2006, which means zfa has more than ten years of butterfly valve production experience.