Introduction:

A check valve is critical in any residential or commercial space and is used in many systems. But do you know what a check valve is?

A check valve is present in pipelines, pump outlets, and more. The main purpose is to prevent the backflow of fluid. Thus, this prevention helps the equipment remain safe and sound.

In the blog, we will discuss a check valve in detail. This guide will take you through different sections, including how to use a check valve, its workings and applications, and how to choose. So, let’s proceed to the discussion.

Understanding What Is A Check Valve?

A check valve is a simple device with a basic operation. Other names for check valves are one-way or non-return valves. A check valve is paramount in pipes with large or small diameters.

The basic operation of a check valve is to keep gases and fluids flowing only in a single direction. It helps keep the system safe and secure. You will see these valves in places where the backflow might cause contamination.

Check valve types can vary in size. They can be small, like a refrigerator, or huge, like in a water processing plant.

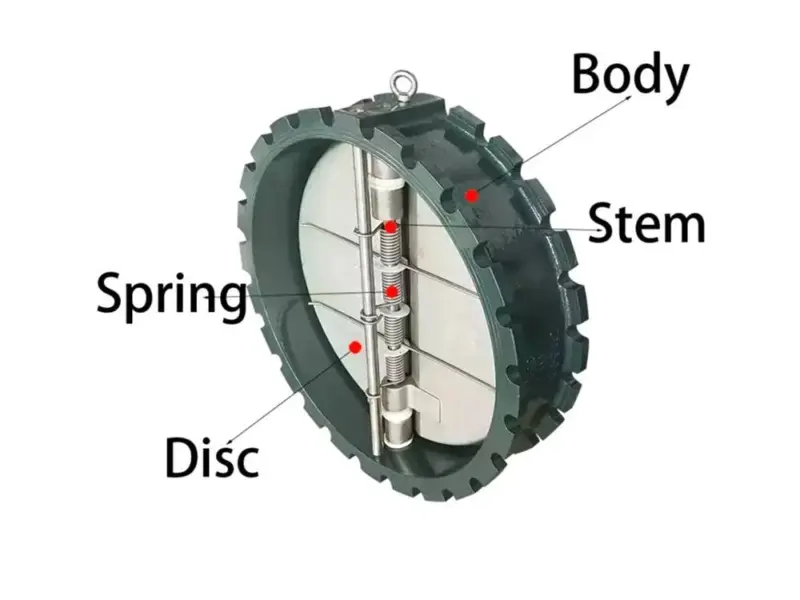

How Does A Check Valve Work?

The working of a check valve is pretty simple. In basic terms, a check valve is a checkpoint in your system. When any fluid applies pressure from inside, it can open the valve and pass with ease. Moreover, when the fluid applies pressure from the outside, the valve closes further. Thus, it ensures that the flow is in a single direction.

Operating these valves requires a complex mechanism. But the reality is completely different. These valves are simple to operate and very reliable. Also, you have to understand that each valve comes with its pressure rating. Yes!

A valve has a certain pressure rating that comes from the manufacturer. Thus, experts suggest that one should not push the valve more than the rating. One needs to install them, and the valve will take care of the system. There is no outside help of a human, or a computer is there for its function.

Thus, it is how a simple check valve works. We observe the flow of liquid when there is cracking pressure. This pressure ensures that the flow of the fluid is unidirectional. The role of the valve is to ensure that the fluid does not move backward, which affects the machinery. Hence, it plays a critical role in the safety of the system.

What Is A Check Valve Used For?

You must be thinking about the role of a check valve. What is its application? This section will help you understand its uses. Before we find its applications, we need to understand the role of a check valve.

So, a check valve’s primary task is to ensure that the fluid moves only in a single direction. The opening of a valve is automatic, using the pressure of the fluid inside it.

Some of the crucial functions of the check valves are:

- These valves avoid the backflow of the fluid in the system.

- It ensures that the pump and the generator do not reverse.

- It stops the backflow of fluid from the container as well.

These are some of the primary roles of a check valve. Based on this, we will find out where to use these valves.

Let us take a pump as an example. Imagine you have a large pump that moves water. When the pump is on, it moves water in a particular direction. But what if it is off? There are many chances that water might flow back. If that happens, there is a high chance that the pump may have issues. Thus, we place a check valve in the right place of the pump. It prevents the backflow of water and thus stops the damage.

Are check valves also in our residential and commercial spaces? Yes! Check valves are present in our toilets. Hence, these valves ensure sewage does not flow back to the toilets.

You can also witness these valves in domestic uses. For example, a valve present in a garden hose, washing machine, and even lawn sprinklers will prevent the water from flowing back. Have you ever seen a chemical mixer working? Yes! In such chemical mixers, you will see a valve that ensures that chemicals do not mix.

Another prominent example of applying a check valve is pipelines for gas. We all know how difficult it will be if some essential gases in a setup get mixed. Do you agree? Thus, you will see a check valve in these systems to prevent the mixing of gases.

How To Choose The Right Check Valve For Your System?

Are you aware of how you can choose the right check valve? Well, by following some basic points, you can ensure that you make the right decision. What are these points? Let us talk about them in detail.

What Kinds Of Fluids You Are Dealing With?

The kind of fluid you are dealing with plays a crucial role in selecting the valve. Some valves work well with normal and suspended fluids, but some work well with only one fluid. Thus, you should choose a valve considering this point.

Most people overlook this point and then face issues later. For example, you choose a valve that is not able to handle suspended solids. With such a valve, you will face issues, and the fluid might flow back.

What Is The Material Of The Valve?

The next point that you need to consider when choosing a valve is to check its material. There is a direct contact between the valve and the liquid. Thus, you should be careful that the valve’s material does not contaminate the liquid.

If you overlook this at any moment, the valve’s material might contaminate the fluid. Some people face this issue only because they overlook this point. Thus, be aware of the material that you select while choosing the valve.

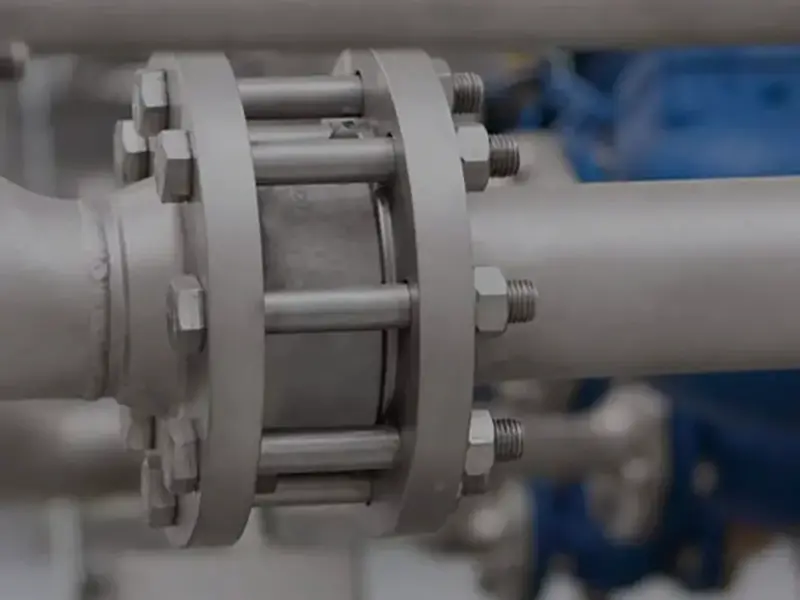

What Is The Size of the Pipe?

Are you looking forward to getting valves in bulk? It is a fantastic step to consider installing in your space. But, it is essential to note that you should be aware of the pipe size.

There are instances when people buy the valve but are not aware of the size of the pipe. In such scenarios, there will be either leakage or the valve not fitting into the pipe. So, get professional help from an expert who will help you calculate the size and make the right decision.

How Much Pressure The Valve Can Handle?

You should be aware that the valve will be able to handle the amount of pressure the liquid will put on it. Yes! While installing, you should double-check if the valve can hold the pressure. Moreover, both the inlet and outlet mechanisms of the valve should work.

What Are The Operating Conditions?

Do you know the conditions under which the valve works? Are the external temperature and the fluid conditions suitable for the valve? After checking these points, you should provide some space for repairs.

What Is The Company That You Are Choosing?

One of the biggest factors you should consider is choosing the right platform. Some platforms, like ZFA Valve, offer the best services you will always cherish. Why?

The first advantage of choosing the right platform is the quality of the products. It is always advisable not to overlook the quality of the check valve. You get options like the Double Doors Wafer Check Valve Duplex Stainless Steel 2205. It would help to choose valves of top materials like stainless steel.

Another advantage of choosing a reputed platform is customer service. What will you do when you face an issue with the product? Choosing the right platform provides you with effective customer service.

These are some of the points that you should always consider. You will always make a good decision when you select a check valve based on this. Contact ZFA Valve for the best services and products.

Wrapping Up!

So, now you know what is a check valve. From the working to the application of a check valve, we discussed things in detail. A simple check valve, basic in function, is present in various devices and industries. We also discussed what does a check valve do and the types of check valves. These valves are super effective in preventing the backward flow of fluids. Be sure that you choose the right platform when purchasing the check valve.