In industrial fluid control systems, it is critical to choose the right valve to ensure the efficiency and reliability of the system. Butterfly valves are widely used in many industries due to their simple structure, easy installation, and low cost.

However, butterfly valves may not be the best choice in some specific application scenarios. Therefore, understanding other valve types and their advantages is essential to choosing the valve that best suits specific needs.

Although there are alternatives such as ball valves, gate valves, and globe valves, butterfly valves often stand out and are particularly suitable for specific applications.

This article will focus on the advantages and disadvantages of alternatives to butterfly valves, revealing why butterfly valves are irreplaceable despite the existence of competing options.

1. Alternatives to Butterfly Valves and Their Advantages and Disadvantages

Despite the many advantages of butterfly valves, other types of valves may be a better choice in some special applications. The following are several common butterfly valve alternative valve types and their main advantages, providing engineers with the basis and data to consider specific needs to choose alternatives.

1.1. Gate Valve

Features:

Design: Gate valves allow or prevent fluid flow by raising or lowering the gate. When fully open, the gate is completely out of the flow path, thereby minimizing resistance to the fluid.

Operation: These valves are usually operated by a handwheel or electric actuator. Due to their design, they can be slow to open and close, especially large valves.

Advantages:

High-pressure capability: Gate valves excel in high-pressure environments because they are able to provide a tight seal.

Unimpeded flow: When fully open, the gate is disengaged from the flow path, ensuring full flow without obstruction.

Applications:

Oil and gas: Gate valves are often used in pipelines that handle high-pressure fluids.

Water distribution: Commonly used in water treatment and distribution systems, especially for isolating sections of pipelines.

Power plants: Used to manage steam and water flow in power generation facilities.

Limitations:

Slower operation: Gate valves take longer to open and close than butterfly valves.

More bulky design: Larger in size, they require more space, making them less suitable for tight installations.

Fully open and fully closed: The gate of a gate valve can only be in the fully open and fully closed positions, making it less suitable for flow regulation.

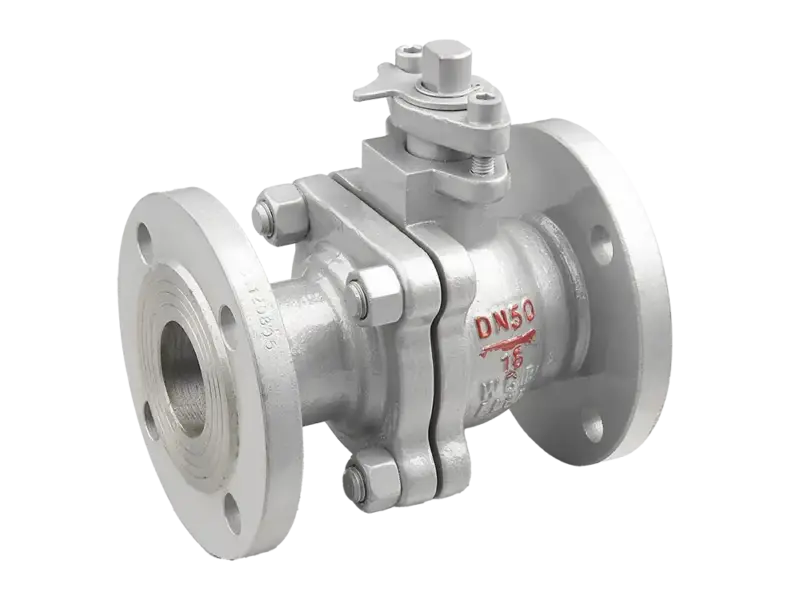

1.2. Ball Valves

Features:

Design: Ball valves use a spherical valve disc with a hole in the middle. When the hole is aligned with the pipe, fluid can pass through. Rotating the ball 90° stops flow.

Operation: Ball valves are typically quarter-turn valves (like butterfly valves), meaning they can be fully opened or closed with a 90° turn.

Advantages:

Good sealing: Ball valves seal tightly with minimal leakage, making them ideal for shutoff applications.

Quick operation: They can be opened or closed quickly, typically with just a quarter turn.

Versatile: Ball valves come in a variety of configurations (full bore, reduced bore) and can handle a variety of fluids, including gases and liquids.

Applications:

Water treatment: Used to control flow in water systems due to their reliable shutoff and low maintenance.

Oil and gas: Used to control the flow of oil and gas in pipelines because they are durable and have a strong seal.

Chemical processing: Ball valves can be used in corrosive chemical environments, especially when high flow rates and fast operation are required.

Limitations:

Cost: Ball valves tend to be more expensive than butterfly valves, both in terms of purchase and installation.

Size: Larger ball valves can be bulkier and require more space than butterfly valves.

1.3. Globe Valves

Features:

Design: Globe valves use a movable plug or disc to regulate flow through an orifice. The flow path is controlled by adjusting the position of the disc within the valve body, providing a high level of throttling control.

Operation: These valves are often used in applications where fine control of flow is required. They are slower to operate and generally require higher torque to turn.

Advantages:

Precise flow control: Ideal for throttling applications where controlling flow is critical.

Durable design: Globe valves can withstand high pressures and temperatures, making them suitable for harsh environments.

Versatile: Can be used with a wide range of fluids, especially for steam and other high-pressure applications.

Applications:

Chemical processing: Globe valves are often used to regulate the flow of chemicals because they allow for fine adjustments to flow.

Power plants: Used to regulate steam and water flow in energy production.

Oil and gas: Often used in piping systems where precise regulation of flow is required.

Limitations:

Higher pressure drop: Due to their design, globe valves produce a significant pressure drop across the valve.

Complexity: More complex in both design and operation than butterfly or ball valves, making them less suitable for simple on/off applications.

2. The Irreplaceable Nature of Butterfly Valves

Although there are many alternative valves available on the market, the unique advantages and combined advantages of butterfly valves make them an irreplaceable first choice in many application scenarios.

2.1 Space Saving:

For systems that need to save space, butterfly valves are unmatched. Because of its short structural length, it can be installed in a smaller space and provide powerful fluid control capabilities.

2.2 Light Weight:

Butterfly valves are much smaller and lighter than gate valves or globe valves, especially large-sized gate valves or globe valves. The larger the size, the greater the weight difference.

2.3 Fast Operation

Butterfly valves use a 90-degree rotation mechanism. This allows butterfly valves to be opened or closed almost instantly. This is the existing opponent of butterfly valves in terms of efficiency.

2.4 Automation

When used with pneumatic or electric actuators, to compose a pneumatic butterfly valve or electric butterfly valve. They can achieve real-time flow control in automated systems, which is essential for fire protection and other industries that require emergency shutdowns.

2.5 Economical

The simple design of butterfly valves requires less material and less processing, which reduces upfront and life cycle costs. The cost-effectiveness of butterfly valves is unmatched in many projects with limited budgets. Especially in industries that require large-scale valves.

2.6 Large Diameter

Butterfly valves are reliable in pipes with diameters greater than 48 inches, while alternatives to butterfly valve such as ball valves and gate valves become too expensive or mechanically impractical.

2.7 Multiple Material Compatibility

Butterfly valve bodies can be made of common materials such as ductile iron and wcb, or corrosion-resistant stainless steel. In addition, by using corrosion-resistant discs (such as stainless steel, PTFE coating) and elastomer seats (such as EPDM, Viton), they can adapt to a variety of media (water, gas, chemicals and mud).

2.8 Wide Range of Applications

Butterfly valves are suitable for a variety of fluid control occasions, especially under medium and low pressure, normal temperature and pressure conditions, butterfly valves can give full play to their advantages. Even in the fields of chemical, food and water treatment, the adaptability of butterfly valves makes them an ideal choice.

2.9 Easy Maintenance

Due to fewer moving parts and easy maintenance design, butterfly valves require less maintenance downtime. The valve seat can usually be replaced or the disc adjusted without removing the valve from the pipeline.

3. Limitations of Alternatives to Butterfly Valves in Critical Applications

Here are specific applications where alternatives to butterfly valves need to be considered for their shortcomings:

3.1 Water Treatment

Butterfly valves dominate here because they are able to handle large flows at low pressure drops. Gate valves cause excessive head loss, while the cost and size of ball valves make them unsuitable for large pipes.

3.2 HVAC Systems

Butterfly valves are compact and can be installed in small spaces above the ceiling or in mechanical rooms. Globe valves, while great for throttling, are too bulky and inefficient for airflow regulation.

3.3 Fire Protection Systems

Speed is critical for fire sprinkler systems, as fire is the fastest-growing disaster, so speed is a must. Butterfly valves activate faster than gate or diaphragm valves, ensuring rapid water delivery in emergency situations.

4. Summary of Alternative to Butterfly Valves

Although gate valves, ball valves and other valves can provide higher sealing or high pressure resistance in certain specific application scenarios, butterfly valves still occupy an irreplaceable position in many industries due to their simple structure, low cost, convenient and fast operation, multiple selectivity and wide applicability. Butterfly valves are the first choice for large-diameter pipelines, space-saving systems, projects with high economic requirements, and flow regulation applications. By understanding the advantages and disadvantages of each valve, industry professionals can make more informed decisions and choose the valve that best suits specific needs.