Gate valves are versatile and popular for their functionality. They control and regulate the flow of liquids. However, the question is how to decide on gate valve sizes. Here is a complete article about selecting the right gate valve sizes. Importance of Gate Valve Dimensions Let’s understand its importance before we learn how to…

Welcome to the world of zfa butterfly valves, where a wide variety of butterfly valves are available, combining reliability and versatility. Butterfly valves are essential components in industrial applications, providing effective opening and closing control for fluids and gases. Understanding the different types of butterfly valve connections is essential to optimizing system performance. Each connection…

When facing a backflow issue, the first question that comes to mind is how to install a check valve. This issue is more prominent in hydraulic cylinders, plumbing systems, and gas lines. A backflow of liquid or gas can damage the internal parts of your machinery. In such cases, check valves come in handy in…

Invitation to Visit Us at FENASAN 2024 Dear Valued Customer, We are excited to invite you to visit our booth at the FENASAN 2024 Exhibition, which will take place from October 22nd to 24th, 2024. This premier event is an excellent opportunity for us to showcase our latest innovations in butterfly valve & gate valve…

The Chinese manufacturing market is very diverse. Many manufacturers produce high-quality valves, and everyone claims to be the best. But it is on us to choose manufacturers carefully. Therefore, Knowing how to choose the right valve manufacturer in China is paramount. During selection, you must consider some key factors. They will help you choose a…

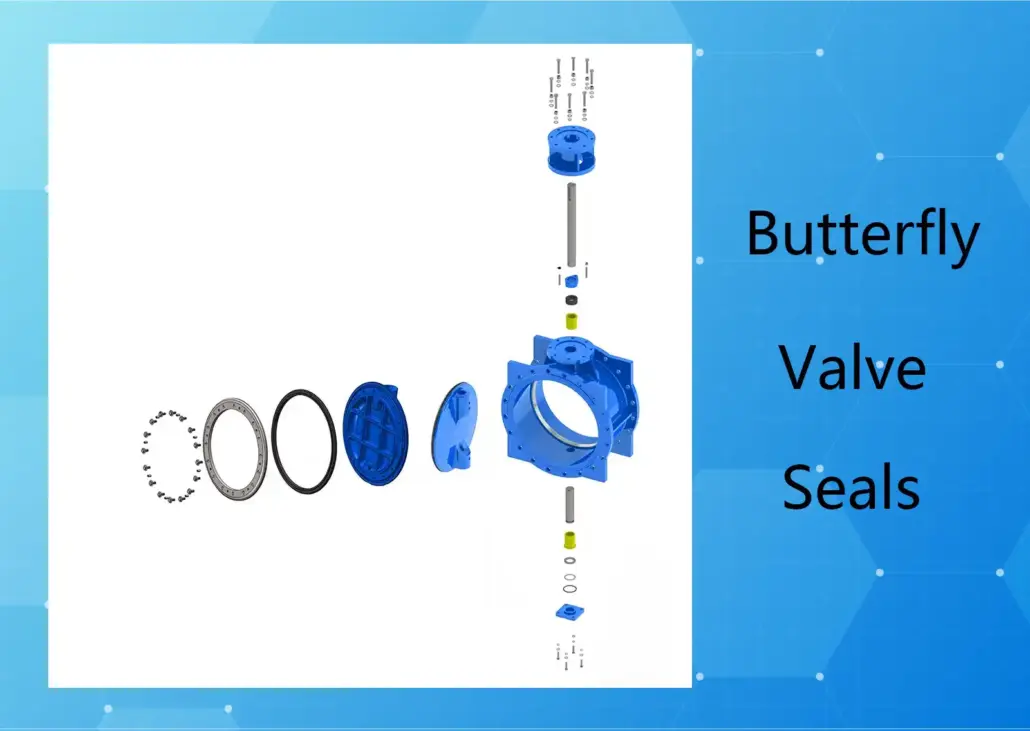

Butterfly valves are versatile and efficient devices for flow control. They are found in many industries that drive the economies of the world. A butterfly valve consists of a disc that rotates on an axis to control the flow of fluid and media. The seal of this device determines its efficiency. The seal of a…

1. Introduction to Butterfly Valve Seals A butterfly valve is a quarter-turn rotary valve that controls the flow of fluids (primarily liquids and gases) by rotating the disc. The butterfly valve seals ensure that the butterfly valve does not leak when it is closed. Seals are available in a variety of designs and materials, depending…

The world of valves is vast. They are critical for diverse industries, including oil, gas, and petrochemicals. Valves’ main purpose is to regulate the flow of liquid. But do you know if there are certain API standards for valves? Proper standards ensure the longevity and functionality of the valves. Here is a blog that explores…

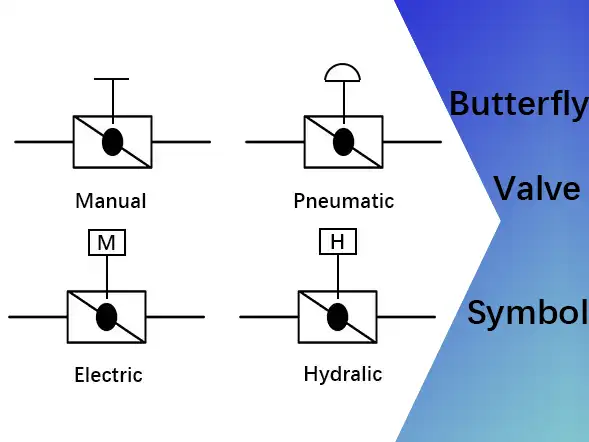

1. Introduction to Butterfly Valves 1.1. What is a Butterfly Valve? A butterfly valve is a quarter-turn valve named for its resemblance to a butterfly. It is used to start, regulate, or stop the flow of fluid in a pipeline. When the valve is open, the disc turns to allow fluid to flow through. When…

Dear Customer: We sincerely invite you to attend the upcoming Exhibition WASTETECH/ECWATECH in Russia. As one of the Chinese leaders in the valve industry, we are looking forward to meeting you face to face. During the exhibition, we will display a variety of flagship butterfly valve products, including centerline butterfly valves, double eccentric valves and…