Actuators of Butterfly Valve

Every butterfly valve requires a force device, and the actuator is the device that provides the force required to operate the valve manually or automatically.

Common actuators used in butterfly valves:

1. Handle actuator:

the most commonly used manual operation of small diameter butterfly valves. Suitable for butterfly valves with DN≤250.

2. Worm gear actuator:

It can reduce the torque through speed ratio and is suitable for manual operation of any caliber.

3. Pneumatic actuator:

Using compressed air to operate the valve, the butterfly valve can be opened and closed quickly.

4. Electric actuator:

Uses electricity to operate the valve. Suitable for applications requiring precise control or requiring automation and remote operation.

Valve Type You Could Choose

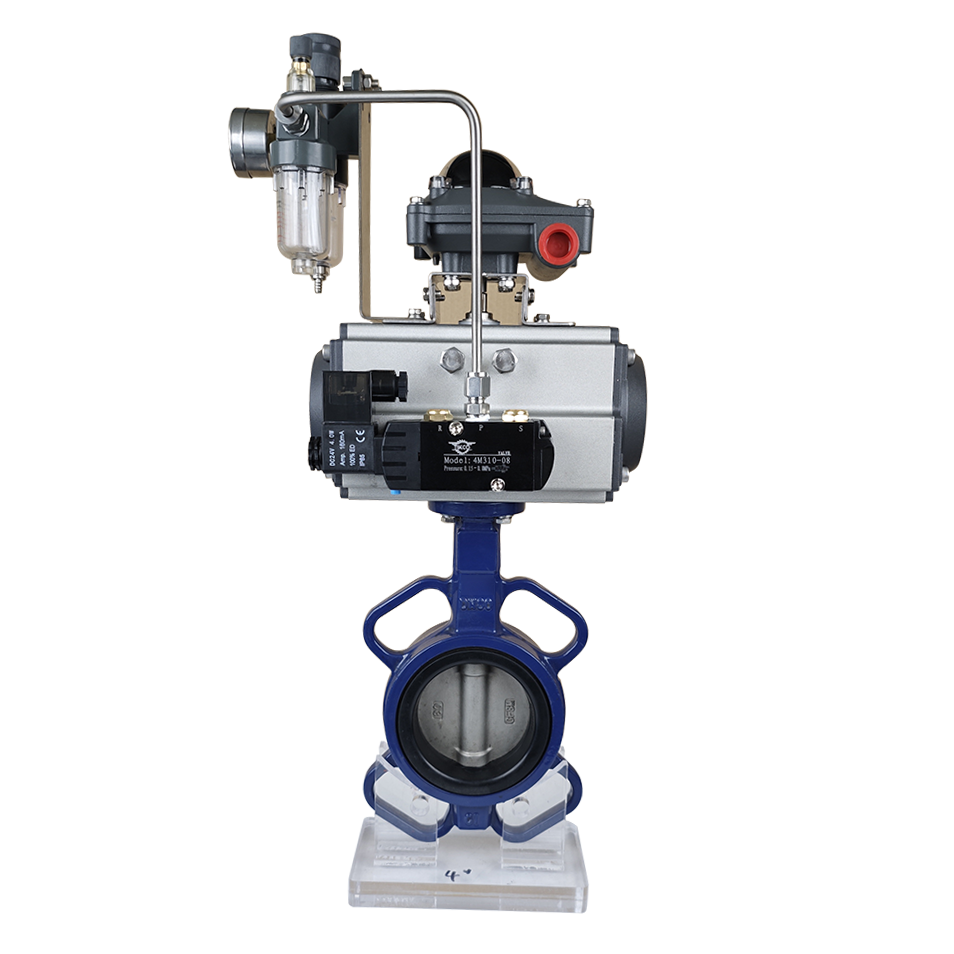

Pneumatic Wafer Butterfly Valve

- Connection: wafer,

- Structure: center line,

- Body material: Ductile Iron(GGG40/50), LCB, Carbon Steel(WCB A216), Stainless Steel(SS304/SS316/SS304L/SS316L) , Duplex Stainless Steel(2507/1.4529).

- Disc material: DI(Ni lined), WCB (A216), Stainless Steel(SS304/SS316/SS304L/SS316L) , Duplex Stainless Steel(2205/2507).

- Seat: Rubber (EPDM, NBR),

- Actuator: Pneumatic Actuator.

- Pressure rating: PN6-PN25.

- Temperature range: -20~+130℃.

Lever Operated Butterfly Valve

- Connection: Flanged,

- Structure: center line,

- Body material: Ductile Iron(GGG40/50), LCB, Carbon Steel(WCB A216), Stainless Steel(SS304/SS316/SS304L/SS316L) , Duplex Stainless Steel(2507/1.4529).

- Disc material: DI(Ni lined), WCB (A216), Stainless Steel(SS304/SS316/SS304L/SS316L) , Duplex Stainless Steel(2205/2507).

- Disc type: Two Pieces.

- Seat: PTFE,

- Actuator Options: Lever

- Pressure rating: PN6-PN40.

- Temperature range: -10~+180℃.

Worm Gear Operated Lug Butterfly Valve

- Connection: Lug,

- Structure: center line,

- Body material: Ductile Iron(GGG40/50), LCB, Carbon Steel(WCB A216), Stainless Steel(SS304/SS316/SS304L/SS316L) , Duplex Stainless Steel(2507/1.4529).

- Disc material: DI(Ni lined), WCB (A216), Stainless Steel(SS304/SS316/SS304L/SS316L) , Duplex Stainless Steel(2205/2507).

- Disc type: Two Pieces.

- Seat: PTFE,

- Actuator Options: Worm Gear.

- Pressure rating: PN6-PN40.

- Temperature range: -10~+180℃.

Electric Double Flanged Butterfly Valve

- Connection: double flange,

- Structure: center line,

- Body material: Ductile Iron(GGG40/50), LCB, Carbon Steel(WCB A216), Stainless Steel(SS304/SS316/SS304L/SS316L) , Duplex Stainless Steel(2507/1.4529).

- Disc material: DI(Ni lined), WCB (A216), Stainless Steel(SS304/SS316/SS304L/SS316L) , Duplex Stainless Steel(2205/2507).

- Seat: Rubber (EPDM, NBR),

- Actuator: Electric Actuator

- Pressure rating: PN6-PN40.

- Temperature range: -20~+130℃.

As you know, the price of butterfly valve requires relatively complex combination calculation, so if you need a free quotation or have any questions, please contact us, we are always here.

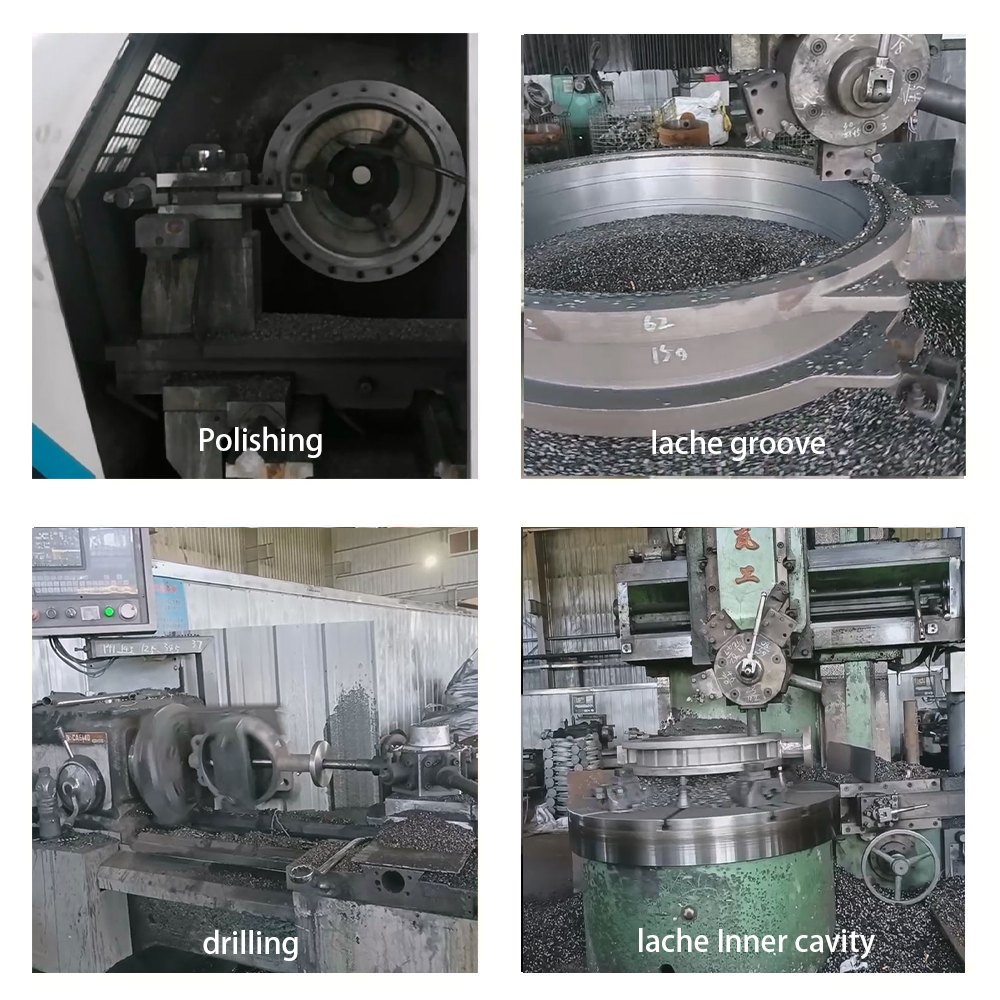

Butterfly Valve Manufacturing Process

We’re a real butterfly valve factory with 17 years production experience, OEM for some customers around the world. All butterfly valves sold by ZFA VALVE are manufactured in our own factory. The excellent quality of our products comes from the meticulous management of the production process. ZFA VALVE is proud to show you our real production scene. Here is our motto: Rigorous production leads to excellent quality!

Step 1: Casting

Step 2:Material Preparation

Step 3:Material Quality Inspection

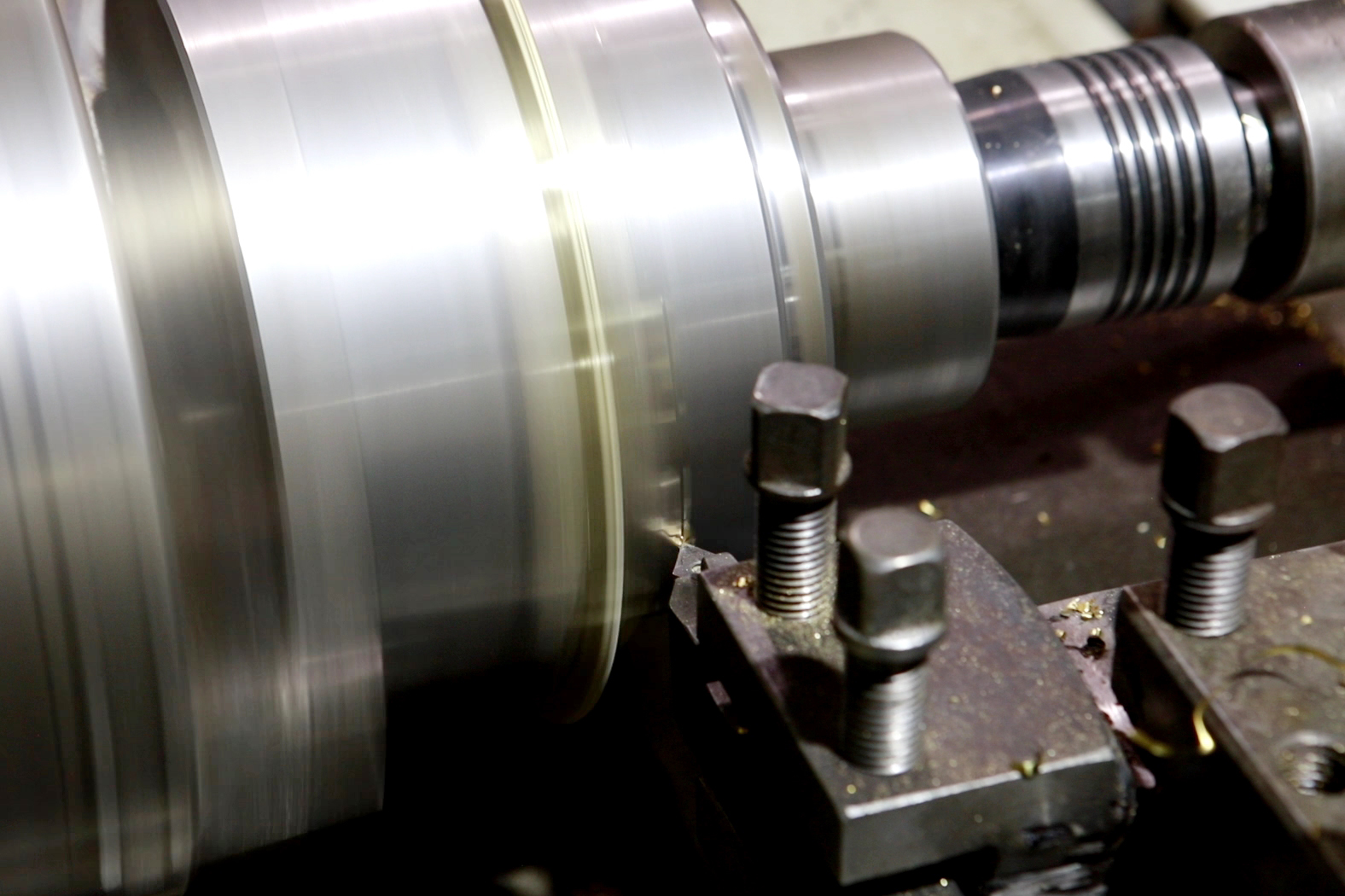

Step 4:Machining Parts

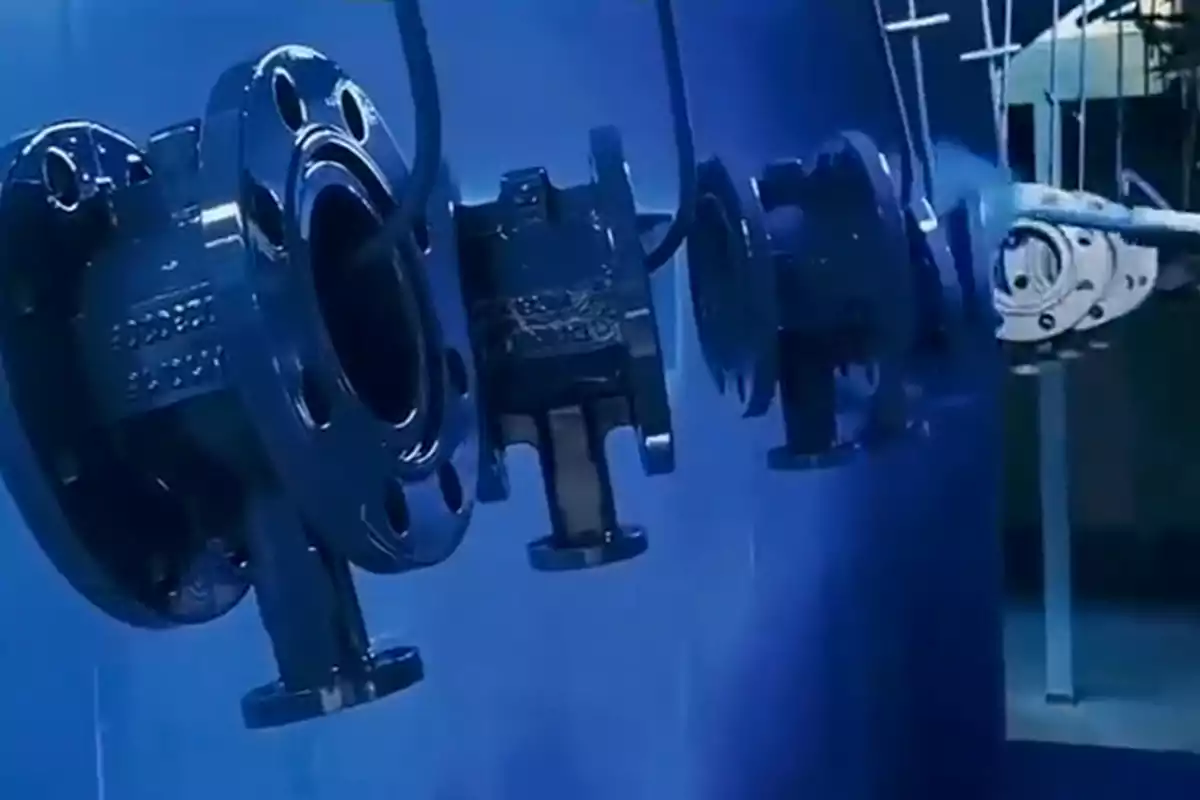

Step 5:Surface Treatment

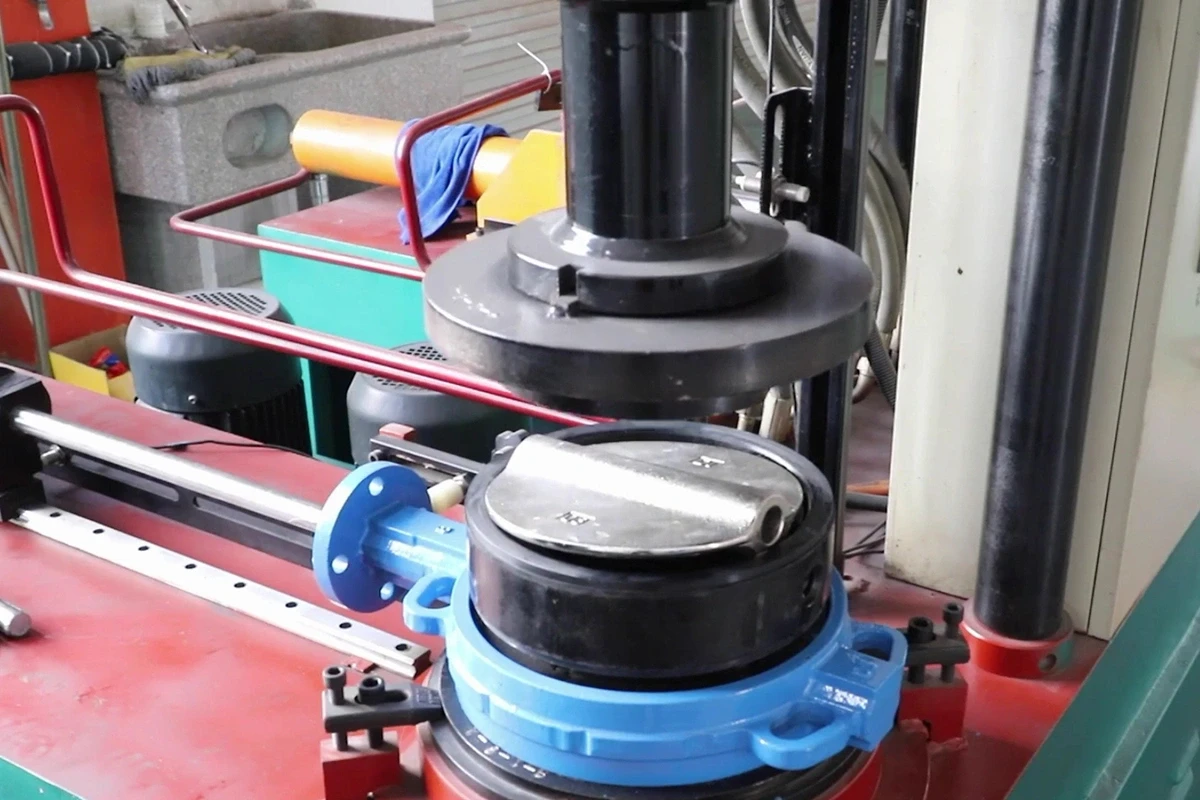

Step 6:Assembly

Step 7:Inspection And Quality Control

Step 8: Packaging

Step 9: Distribution

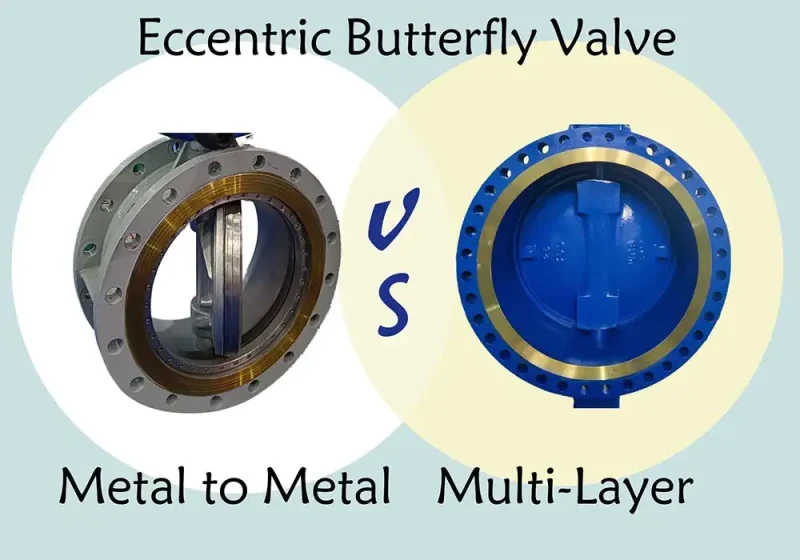

Producing Process of Butterfly Valve Parts

Valve Body of Butterfly Valve

Valve Disc of Butterfly Valve

Soft-backed Seat of Butterfly Valve

Factory Overview

Get More Videos about MANUFACTURING PROCESS, and CAD DAWING about the butterfly valve, please contact us!

Certificates