Basic Info of WCB High Performance Wafer Butterfly Valve

- Tight Seal: Eccentric disc design ensures a tight seal, minimizing leakage and preventing fluid loss.

- High performance: This high performance wafer butterfly valve is well-designed, as its name. Because it has reliable sealing performance and fluid control capabilities. And it can adapt to various working conditions.

- Energy saving and environmental protection: The wafer high-performance butterfly valve may adopt an advanced design. It can reduce fluid resistance and reduce energy consumption. So they meet the requirements of energy saving and environmental protection.

- WCB carbon steel valve body: has excellent mechanical strength and wear resistance. It is suitable for media such as water, oil, and gas.

- RPTFE Seat refers to Reinforced Polytetrafluoroethylene. It is an enhanced PTFE material that offers better wear and chemical resistance.

- CF8M Disc: Cast Stainless Steel, 316 equivalent, can provide excellent corrosion resistance.

- Space-Saving Design: The high-performance butterfly Valve Wafer Pattern short FTF design makes it a suitable choice for limited space applications.

WCB HP Butterfly Valve Standards

| ITEM | Standard |

| Design | EN593 | API609 |

| Face to Face | EN558-20 | ISO5752-20 | API608 Table 1 | BS5155-4 |

| Top Flange | ISO5211 |

| Flange Drilling | PN6 | PN10 | PN16 | ASME B16.5 CL150 | JIS 10K |

| Pressure Rating | PN6 | PN10 | PN16 | PN25 | CL150 | JIS 10K |

| Tightness Test | ISO5208 | API598 | EN12266-1 |

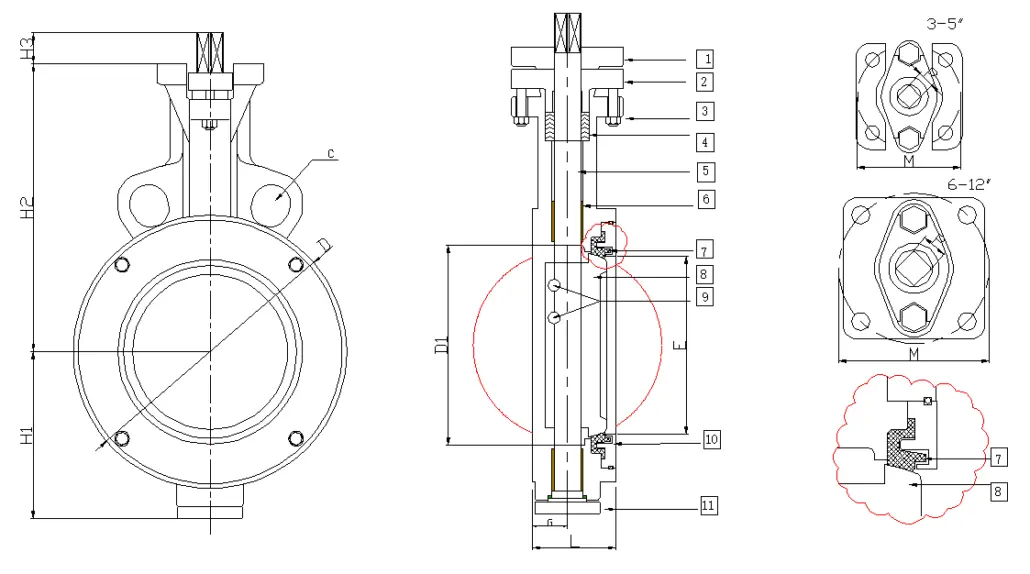

Paraments of Wafer High Performance Butterfly Valve

| size | H1 | H2 | H3 | L | D | D1 | E | P | M | C | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 10K | PN16 | 150LB | ||||||||||

| DN50 | 72 | 137 | 16 | 43 | 96 | 58 | 50 | 11 | F07 | 120 | 125 | 120.5 |

| DN65 | 80 | 152 | 16 | 49 | 119 | 75 | 59 | 11 | F07 | 140 | 145 | 139.5 |

| DN80 | 87 | 162 | 16 | 49 | 128 | 91 | 72 | 11 | F07 | 150 | 160 | 152.5 |

| DN100 | 102 | 177 | 17 | 54 | 158 | 114 | 96 | 11 | F07 | 175 | 180 | 190.5 |

| DN125 | 120 | 195 | 19 | 56 | 186 | 138 | 120 | 14 | F07 | 210 | 210 | 216 |

| DN150 | 132 | 217 | 19 | 56 | 216 | 142 | 142 | 14 | F10 | 240 | 240 | 241.5 |

| DN200 | 167 | 246 | 25 | 64 | 265 | 208 | 190 | 19 | F10 | 290 | 295 | 298.5 |

| DN250 | 205 | 298 | 28 | 71 | 320 | 265 | 238 | 22 | F12 | 355 | 355 | 362 |

| DN300 | 245 | 335 | 32 | 81 | 378 | 310 | 282 | 27 | F12 | 400 | 410 | 432 |

Applications of RPTFE High Performance Butterfly Valve

- Oil and Gas Industry:

-For pipeline isolation, fuel delivery and refining processes.

-Handles hydrocarbons, gases and corrosive fluids.

-Applicable to fluids from -100 degrees Celsius to 260 degrees Celsius. - Chemical Processing

-Applicable to handling corrosive chemicals and acids.

-For chemical delivery lines, storage tanks and process control. - Power Plants

-For steam systems, cooling water and feedwater control.

-CF8M valve discs are corrosion resistant in water and steam environments. - Water and Wastewater Treatment

-Applicable to filtration, desalination and industrial water treatment.

-Handles chlorinated water and other process chemicals.

-Provides reliable on/off control and flow regulation. - HVAC and Building Services

-For chilled water and hot water distribution systems.

-Ensures effective flow control in heating and cooling systems.

-RPTFE valve seats provide low friction and smooth operation. - Food and Beverage Industry

-Applicable to processing oils, beverages and dairy products

-RPTFE valve seats ensure contamination-free, hygienic operation.

-CF8M valve discs are hygienic and corrosion resistant

Manufacture Process of Butterfly Valve

High Performance Butterfly Valve Certificates

WRAS

CE

ISO 9001

EAC Russia