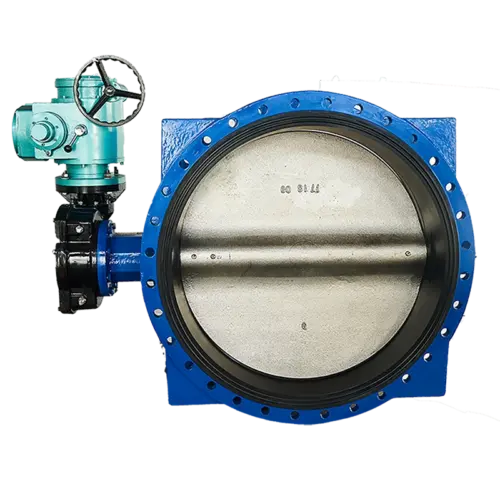

AWWA C504 Ductile Iron Double Eccentric Butterfly Valves

Basic Info of Awwa C504 Eccentric Butterfly Valve

- AWWA C504 is designed to ensure the reliability and functionality of rubber seated butterfly valves used in water supply systems.

- Good sealing performance: The double eccentric design of awwa c504 butterfly valve keeps the contact surface between the valve seat and the valve plate at one point, effectively avoiding friction and wear between the valve seat and the valve plate, thereby providing excellent sealing performance and preventing medium leakage.

- Corrosion resistance: The eccentric butterfly valve body and valve plate of the electric double eccentric flange butterfly valve can be made of corrosion-resistant materials, which can adapt to the requirements of various corrosive media and extend the service life of the valve.

- High flow capacity: Due to the characteristics of the double eccentric design, the valve plate of the electric double eccentric flange butterfly valve will not cause friction with the valve seat during the opening process, and can provide a large flow capacity and is suitable for systems requiring large flow rates.

| Parts | Ductile Iron type | WCB type | Stainless Steel Type | Duplex Stainless Steel Type |

| Body | Cast Iron(GG25) Ductile Iron(GGG40/50) |

A216 A217 A105(forged) |

SS304/ CF8 SS316/CF8M SS304L/CF3 SS316L/CF3M |

2205 2507 1.4529 |

| Disc | Ductile Iron with Ni coated Ductile Iron with nylon coated Ductile Iron with PTFE/EPDM lined Stainless Steel Duplex Stainless Steel Bronze |

SS304/ CF8 SS316/CF8M SS304L/CF3 SS316L/CF3M 2205 2507 1.4529 |

2205 2507 1.4529 |

|

| Seat | NBR, EPDM, PTFE, Viton, Hypalon, Silicon, PFA | |||

| Stem | SS416, SS431, SS304, SS316, Duplex Stainless Steel, Monel | Duplex Stainless Steel, Monel | ||

| Actuator | Worm Gear, Electric, Pneumatic | |||

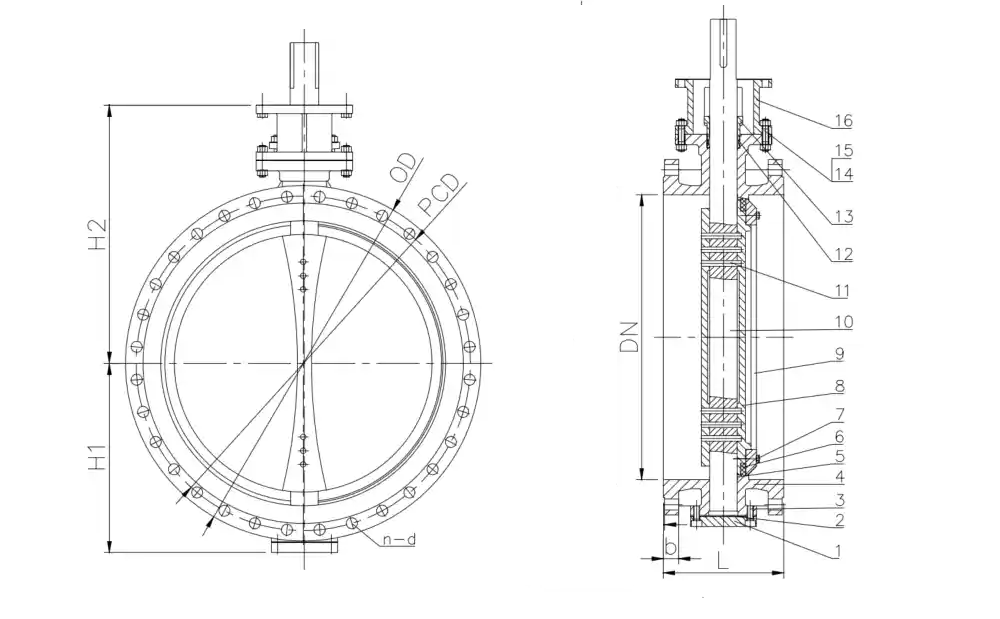

Paraments of Short Body AWWA C504 Eccentric Butterfly Valve

| NPS | DN | C504 | OD | PCD | d | f | b | n-d | H1 | H2 |

| 14” | 350 | 203 | 535 | 476.3 | 413 | 1.5 | 34.9 | 12-φ28.6 | 303 | 423 |

| 16” | 400 | 203 | 595 | 539.8 | 470 | 1.5 | 36.5 | 16-φ28.6 | 342 | 453 |

| 18” | 450 | 203 | 635 | 577.9 | 533 | 1.5 | 39.6 | 16-φ31.8 | 357 | 478 |

| 20〞 | 500 | 203 | 700 | 635 | 584 | 1.5 | 42.8 | 20-φ31.8 | 400 | 490 |

| 24〞 | 600 | 203 | 815 | 749.3 | 692 | 1.5 | 47.6 | 20-φ35 | 455 | 520 |

| 28” | 700 | 305 | 927 | 863.6 | 800.1 | 1.5 | 51 | 28-φ35 | 517 | 667 |

| 30〞 | 750 | 305 | 985 | 914.4 | 857 | 1.5 | 54 | 28-φ35 | 530 | 667 |

| 32” | 800 | 305 | 1060 | 977.9 | 914.4 | 1.5 | 57 | 28-φ41.2 | 572 | 720 |

| 36” | 900 | 305 | 1170 | 1085.9 | 1022.4 | 1.5 | 60.3 | 32-φ41.2 | 627 | 760 |

| 40” | 1000 | 305 | 1289 | 1200.2 | 1124 | 1.5 | 63.5 | 36-φ41.2 | 585 | 845 |

| 42” | 1050 | 305 | 1345 | 1257.3 | 1194 | 1.5 | 66.7 | 36-φ41.2 | 870 | 920 |

| 48” | 1200 | 381 | 1510 | 1422.4 | 1358.9 | 1.5 | 69.9 | 44-φ41.2 | 920 | 977 |

| 54” | 1350 | 381 | 1685 | 1594 | 1511 | 1.5 | 76.2 | 44-φ41.2 | 950 | 1060 |

| 56” | 1400 | 381 | 1.5 | 48-φ41.2 | 1035 | 1190 | ||||

| 60” | 1500 | 381 | 1855 | 1759 | 1640 | 1.5 | 79.4 | 52-φ50.8 | 1090 | 1245 |

| 64” | 1600 | 457 | 1975 | 1880 | 1750 | 1.5 | 81 | 52-φ50.8 | 1150 | 1410 |

| 66” | 1650 | 457 | 2032 | 1930 | 1830 | 1.5 | 85.7 | 52-φ50.8 | 1180 | 1440 |

| 72” | 1800 | 457 | 2195 | 2096 | 1950 | 1.5 | 88.9 | 60-φ50.8 | 1250 | 1510 |

Manufacture Process

Certificates of Zfa Valve

WRAS

CE

ISO 9001

EAC Russia