DN250 Manual Gear Hard Back Seat Pin Lug Butterfly Valve

Basic Info of Manual Gear Hard Back Seat Pin Lug Butterfly Valve

- Gear operated with worm gear mechanism, easy to control large diameter pin lug butterfly valve.

- Self-locking gear system to prevent accidental movement and ensure position stability.

- Lug type, allows easy bolting on pipe flange to ensure safe installation and easy removal of pipes, and can remove one-side pipe for maintenance.

- Hard back seat, with enhanced stability and durability.

- pin lug butterfly valve means the disc is connected to the stem using a pin, which transmits the torque from the actuator or handle.

- Leakage grade: Bidirectional sealing 0 leakage, meets ANSI IV or V sealing standards.

Material Options of Pin Lug Butterfly Valve

| Parts | Ductile Iron type | WCB type | Stainless Steel Type | Duplex Stainless Steel Type |

|---|---|---|---|---|

| Body | Cast Iron(GG25) Ductile Iron(GGG40/50) |

A216 A217 A105(forged) |

SS304/ CF8 SS316/CF8M SS304L/CF3 SS316L/CF3M |

2205 2507 1.4529 |

| Disc | Ductile Iron with Ni coated Ductile Iron with nylon coated Ductile Iron with PTFE/EPDM lined Stainless Steel Duplex Stainless Steel Bronze |

SS304/ CF8 SS316/CF8M SS304L/CF3 SS316L/CF3M 2205 2507 1.4529 |

2205 2507 1.4529 |

|

| Seat | NBR, EPDM, PTFE, Viton, Hypalon, Silicon, PFA | |||

| Stem | SS416, SS431, SS304, SS316, Duplex Stainless Steel, Monel | Duplex Stainless Steel, Monel | ||

| Actuator | Hand Lever, Worm Gear, Electric, Pneumatic | |||

Lug style Butterfly Valve Standards

| ITEM | Standard |

| Design | EN593 | API609 |

| Face to Face | EN558 | ISO5752 | API608 | BS5155-4 |

| Top Flange | ISO5211 |

| Flange Drilling | PN6 | PN10 | PN16 | ASME B16.5 CL150 | JIS 10K |

| Pressure Rating | PN6 | PN10 | PN16 | PN25 | CL150 | JIS 10K |

| Tightness Test | ISO5208 | API598 | EN12266-1 |

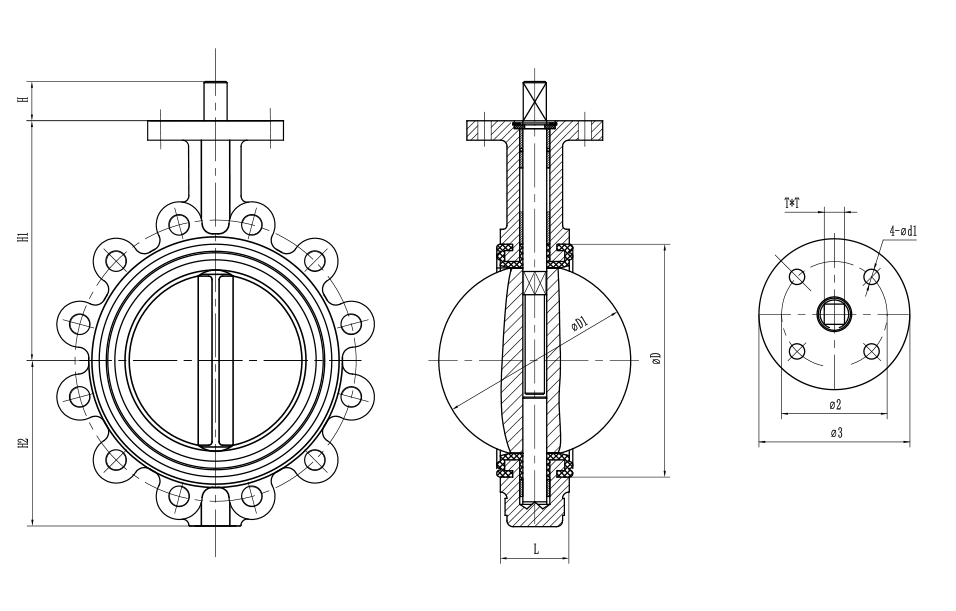

Paraments of Pin Lug Butterfly Valve

| SIZE | øD | øD1 | L | L1 | H | H1 | H2 | ∅2 | ø3 | 4-ødl | T*T |

|---|---|---|---|---|---|---|---|---|---|---|---|

| DN50 | 76.3 | 52.8 | 43 | 46 | 30 | 140 | 60 | 70 | 90 | 10 | 11*11 |

| DN65 | 89 | 64.6 | 45.6 | 49 | 30 | 150 | 67 | 70 | 90 | 10 | 11*11 |

| DN80 | 103.9 | 79.1 | 45.6 | 48 | 30 | 160 | 87 | 70 | 90 | 10 | 11*11 |

| DN100 | 135 | 104.4 | 52.0 | 56 | 30 | 180 | 105 | 70 | 90 | 10 | 11*11 |

| DN125 | 159 | 123.3 | 56.0 | 60 | 30 | 190 | 118 | 70 | 90 | 10 | 14*14 |

| DN150 | 188.4 | 155.6 | 56.0 | 60 | 30 | 210 | 130 | 70 | 90 | 10 | 14*14 |

| DN200 | 238.2 | 202.5 | 60.0 | 64 | 35 | 235 | 166 | 102 | 125 | 12 | 17*17 |

| DN250 | 292.4 | 250.5 | 68.0 | 72 | 35 | 270 | 197 | 102 | 125 | 12 | 22*22 |

| DN300 | 344.2 | 301.6 | 78.0 | 83 | 35 | 305 | 231 | 102 | 125 | 12 | 22*22 |

| DN350 | 375.2 | 333.4 | 78.0 | 83 | 35 | 360 | 255 | 125 | 150 | 14 | 22*22 |

| DN400 | 439.5 | 389.6 | 102.0 | 106 | 50 | 381 | 293 | 140 | 175 | 18 | 27*27 |

| DN450 | 490.5 | 440.5 | 114.0 | 118 | 50 | 425 | 325 | 140 | 175 | 18 | 27*27 |

| DN500 | 535.4 | 491.6 | 127.0 | 132 | 50 | 470 | 363 | 140 | 175 | 18 | 36*36 |

| DN600 | 653.7 | 592.5 | 153 | 159 | 60 | 565 | 425 | 165 | 210 | 22 | 36*36 |

Manufacture Process of Lug Butterfly Valve

Certificates of ZFA Valve

WRAS

CE

ISO 9001

EAC Russia