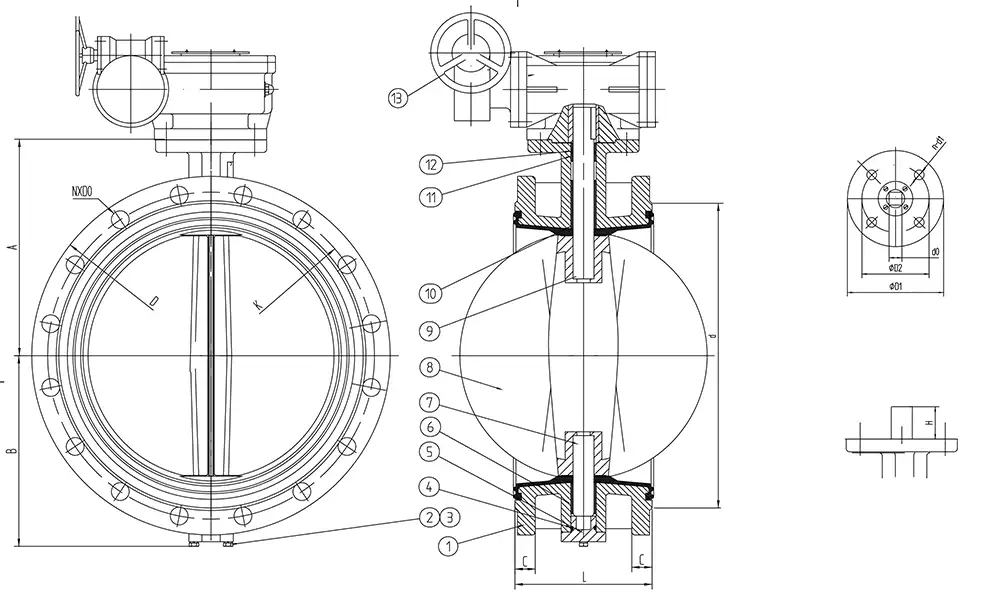

Two Shaft Ducitle Iron Butterfly Valve with Worm Gear

Basic Info of Butterfly Valve with Worm Gear

- Butterfly valve with Worm Gear: Proper worm gear speed ratio can reduce the force required to open and close the valve.

- Ductile iron butterfly valve with DI body/disc: GGG50 butterfly valve is the most commonly used butterfly valve, which has high tensile strength and good anti-corrosion characteristic.

- Vulcanized valve seat: A special manufacturing process is adopted, in which the rubber and the double flanged valve body are integrated through high-temperature vulcanization. This method makes the valve seat and valve body tightly combined and difficult to separate.

- Two stems type:make the disc flat and allow more flow, less resistance to the flow and more mechanical resistance.

- Efficient Flow Control: This ductile iron butterfly valve with worm gear is designed to quickly and effectively control the flow of fluid when opening and closing. The butterfly plate inside the valve can rotate 90 degrees to fully open or close the valve. This design provides lower flow resistance, allowing for higher flow rates and more efficient fluid control.

- Simple Installation: The Flanged Butterfly Valve features a double flange design that can be easily installed between flanged pipe connections. This design makes installation of the valve easier and faster, reducing possible problems and delays during installation.

| Parts | Ductile Iron type | WCB/LCB type | Stainless Steel Type | Duplex Stainless Steel Type |

| Body | Cast Iron(GG25) Ductile Iron(GGG40/50) |

A216 A217 A105(forged)LCB |

SS304/ CF8 SS316/CF8M SS304L/CF3 SS316L/CF3M |

2205 2507 1.4529 |

| Disc | Ductile Iron with Ni coated Ductile Iron with nylon coated Ductile Iron with PTFE/EPDM lined Stainless Steel Duplex Stainless Steel Bronze |

SS304/ CF8 SS316/CF8M SS304L/CF3 SS316L/CF3M 2205 2507 1.4529 |

2205 2507 1.4529 |

|

| Seat | NBR, EPDM, PTFE, Viton, Hypalon, Silicon, PFA | |||

| Stem | SS416, SS431, SS304, SS316, Duplex Stainless Steel, Monel | Duplex Stainless Steel, Monel | ||

| Actuator | Worm Gear, Electric, Pneumatic | |||

Paraments of Butterfly Valve with Worm Gear

| DN | 0 | K | Nxd0 | d | C | L | f | A | B | 01 | 02 | 0-d1 | d0 | H | |||||

| PN10 | PN16 | PN10 | PN16 | PN10 | PN16 | PN10 | PN16 | PN10 | PN16 | ||||||||||

| DN250 | 395 | 405 | 350 | 355 | 12xφ23 | 12xφ28 | 319 | 22 | 165 | 3 | 266 | 198 | 125 | 102 | 4-12 | 22X22 | 35 | ||

| DN300 | 445 | 460 | 400 | 410 | 12xφ23 | 12xφ28 | 370 | 24.5 | 178 | 4 | 298 | 223 | 125 | 102 | 4-12 | 22X22 | 35 | ||

| DN350 | 505 | 520 | 460 | 470 | 16xφ23 | 16xφ28 | 429 | 24.5 | 26.5 | 190 | 4 | 310 | 254 | 150 | 125 | 4-14 | 22X22 | 35 | |

| DN400 | 565 | 580 | 515 | 525 | 16xφ28 | 16xφ31 | 480 | 245 | 28 | 216 | 4 | 340 | 278 | 175 | 140 | 4-18 | 27X27 | 50 | |

| DN500 | 670 | 715 | 620 | 650 | 20xφ28 | 20xφ34 | 582 | 609 | 265 | 32 | 229 | 4 | 430 | 348 | 175 | 140 | 4-18 | 36X36 | 50 |

| DN600 | 780 | 840 | 725 | 770 | 20xφ31 | 20xφ37 | 682 | 720 | 30 | 36 | 267 | 5 | 500 | 410 | 210 | 165 | 4-22 | 36X36 | 60 |

| DN700 | 895 | 910 | 840 | 24xφ31 | 24xφ37 | 794 | 325 | 395 | 292 | 5 | 560 | 480 | 300 | 254 | 8-18 | φ6335 | 80 | ||

| DN800 | 1015 | 1025 | 950 | 24xφ34 | 24xφ40 | 901 | 35 | 41 | 318 | 5 | 620 | 530 | 300 | 254 | 8-18 | φ6335 | 80 | ||

| DN900 | 1115 | 1125 | 1050 | 28xφ34 | 28xφ40 | 1001 | 36 | 44 | 330 | 5 | 685 | 605 | 300 | 254 | 8-18 | φ75 | 100 | ||

| DN1000 | 1230 | 1255 | 1160 | 1170 | 28xφ37 | 28xφ43 | 1112 | 40 | 50 | 410 | 5 | 735 | 670 | 300 | 254 | 8-18 | φ80 | 100 | |

| DN1200 | 1455 | 1485 | 1380 | 1390 | 32xφ40 | 32xφ49 | 1328 | 45 | 57 | 470 | 5 | 917 | 780 | 350 | 298 | 8-22 | φ90 | 100 | |

Manufacture Process of Butterfly Valve

Certificates of Zfa Valve

WRAS

CE

ISO 9001

EAC Russia