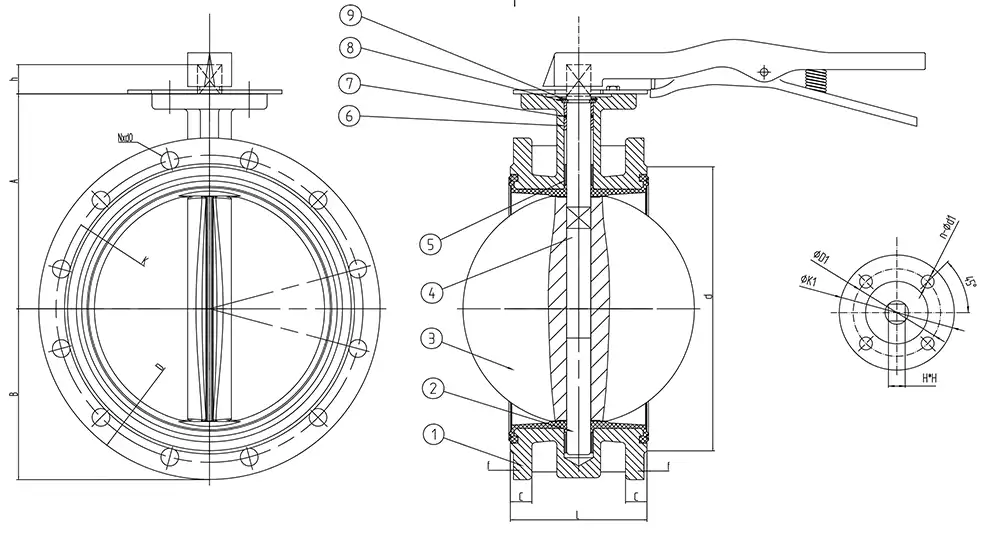

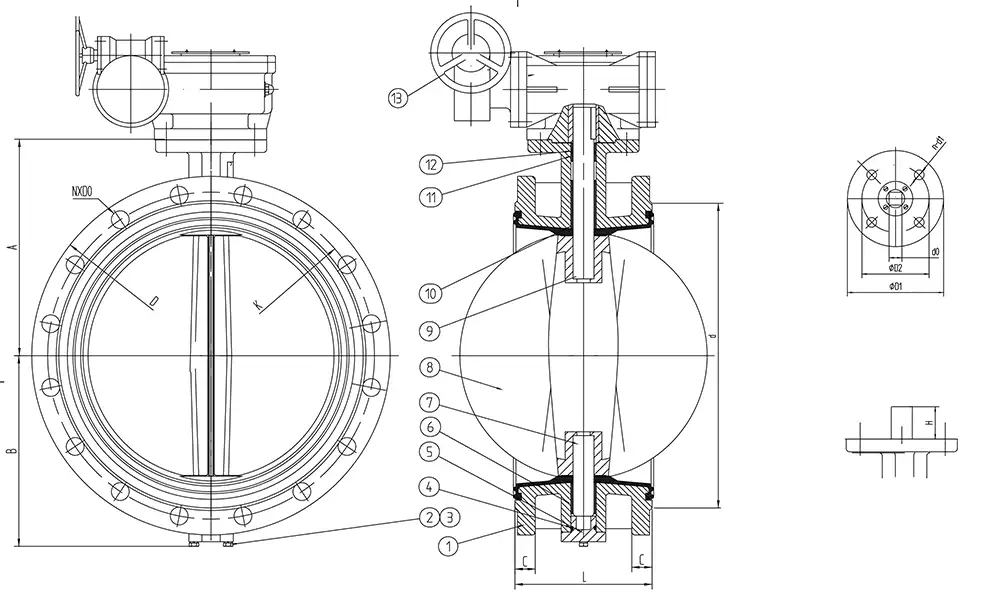

Ductile Iron Replaceable Soft Seat Double Flange Butterfly Valve

Basic Info of Double Flange Butterfly Valve

- The double flange butterfly valve body is made of ductile iron (also known as spheroidal graphite cast iron), which has excellent strength, toughness and is suitable for handling low to medium pressure fluids. At the same time, the ductile iron valve body has excellent corrosion resistance, especially in water and wastewater applications.

- The disc is made of CF8 stainless steel, which is corrosion-resistant, especially in environments involving water, steam and weak acids.

- Soft valve seat: EPDM has good sealing and wear resistance, and can achieve zero leakage.

- Replaceable soft seat: When the valve seat is worn and affects use, this type of seat can be replaced without damaging the valve body, so that it facilitates maintenance, extends the service life of the valve, and reduces maintenance costs.

- Double flange design ensures the soft seat butterfly valve is easy for installation and is suitable for various pipeline systems, including pipeline end systems.

Advantage:

- Durability: The ductile iron and CF8 stainless steel ensure a long service life.

- Leak-Free Performance: The replaceable soft seat butterfly valve ensures leak-free operation.

- Easy Maintenance: The replaceable soft seat simplifies maintenance and reduces overall costs.

- Corrosion Resistance: Both the body and disc are corrosion-resistant, making this valve ideal for use in water and wastewater systems.

Double Flange Butterfly Valve Parts

| Parts | Ductile Iron type | WCB type | Stainless Steel Type | Duplex Stainless Steel Type |

|---|---|---|---|---|

| Body | Cast Iron(GG25) Ductile Iron(GGG40/50) |

A216 A217 A105(forged) |

SS304/ CF8 SS316/CF8M SS304L/CF3 SS316L/CF3M |

2205 2507 1.4529 |

| Disc | Ductile Iron with Ni coated Ductile Iron with nylon coated Ductile Iron with PTFE/EPDM lined Stainless Steel Duplex Stainless Steel Bronze |

SS304/ CF8 SS316/CF8M SS304L/CF3 SS316L/CF3M 2205 2507 1.4529 |

2205 2507 1.4529 |

|

| Seat | NBR, EPDM, PTFE, Viton, Hypalon, Silicon, PFA | |||

| Stem | SS416, SS431, SS304, SS316, Duplex Stainless Steel, Monel | Duplex Stainless Steel, Monel | ||

| Actuator | Hand Lever, Worm Gear, Electric, Pneumatic | |||

Double Flanged Soft Seat Butterfly Valve Standards

| ITEM | Standard |

| Design | EN593 | API609 |

| Face to Face | EN558 | ISO5752 | API608 | BS5155-4 |

| Top Flange | ISO5211 |

| Flange Drilling | PN6 | PN10 | PN16 | ASME B16.5 CL150 | JIS 10K |

| Pressure Rating | PN6 | PN10 | PN16 | PN25 | CL150 | JIS 10K |

| Tightness Test | ISO5208 | API598 | EN12266-1 |

Paraments of Soft Seat Double Flange Butterfly Valve

| DN | D | K | Nxd0 | d | C | L | f | A | B | K1 | 01 | n-d1 | HXH | h | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| PN10 | PN16 | PN10 | PN16 | PN10 | PN16 | PN10 | PN16 | PN10 | PN16 | ||||||||||

| DN50 | 165 | 125 | 4xφ18 | 99 | 19 | 108 | 3 | 139 | 80 | 65 | 50 | 4-8 | 11X11 | 30 | |||||

| DN65 | 185 | 145 | 4xφ18 | 118 | 19 | 112 | 3 | 146 | 89 | 65 | 50 | 4-8 | 11X11 | 30 | |||||

| DN80 | 200 | 160 | 8xφ18 | 132 | 19 | 114 | 3 | 150 | 95 | 65 | 50 | 4-8 | 11X11 | 30 | |||||

| DN100 | 220 | 180 | 8xφ18 | 156 | 19 | 127 | 3 | 177 | 114 | 90 | 70 | 4-10 | 11X11 | 30 | |||||

| DN125 | 250 | 210 | 8xφ18 | 184 | 19 | 140 | 3 | 178 | 125 | 90 | 70 | 4-10 | 14X14 | 30 | |||||

| DN150 | 285 | 240 | 8xφ22 | 211 | 20 | 140 | 3 | 201 | 139 | 90 | 70 | 4-10 | 14X14 | 30 | |||||

| DN200 | 340 | 295 | 8xφ22 | 12xφ22 | 270 | 20 | 152 | 3 | 230 | 170 | 125 | 102 | 4-12 | 17X17 | 35 | ||||

| DN | 0 | K | Nxd0 | d | C | L | f | A | B | 01 | 02 | 0-d1 | d0 | H | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| PN10 | PN16 | PN10 | PN16 | PN10 | PN16 | PN10 | PN16 | PN10 | PN16 | ||||||||||

| DN250 | 395 | 405 | 350 | 355 | 12xφ23 | 12xφ28 | 319 | 22 | 165 | 3 | 266 | 198 | 125 | 102 | 4-12 | 22X22 | 35 | ||

| DN300 | 445 | 460 | 400 | 410 | 12xφ23 | 12xφ28 | 370 | 24.5 | 178 | 4 | 298 | 223 | 125 | 102 | 4-12 | 22X22 | 35 | ||

| DN350 | 505 | 520 | 460 | 470 | 16xφ23 | 16xφ28 | 429 | 24.5 | 26.5 | 190 | 4 | 310 | 254 | 150 | 125 | 4-14 | 22X22 | 35 | |

| DN400 | 565 | 580 | 515 | 525 | 16xφ28 | 16xφ31 | 480 | 245 | 28 | 216 | 4 | 340 | 278 | 175 | 140 | 4-18 | 27X27 | 50 | |

| DN500 | 670 | 715 | 620 | 650 | 20xφ28 | 20xφ34 | 582 | 609 | 265 | 32 | 229 | 4 | 430 | 348 | 175 | 140 | 4-18 | 36X36 | 50 |

| DN600 | 780 | 840 | 725 | 770 | 20xφ31 | 20xφ37 | 682 | 720 | 30 | 36 | 267 | 5 | 500 | 410 | 210 | 165 | 4-22 | 36X36 | 60 |

| DN700 | 895 | 910 | 840 | 24xφ31 | 24xφ37 | 794 | 325 | 395 | 292 | 5 | 560 | 480 | 300 | 254 | 8-18 | φ6335 | 80 | ||

| DN800 | 1015 | 1025 | 950 | 24xφ34 | 24xφ40 | 901 | 35 | 41 | 318 | 5 | 620 | 530 | 300 | 254 | 8-18 | φ6335 | 80 | ||

| DN900 | 1115 | 1125 | 1050 | 28xφ34 | 28xφ40 | 1001 | 36 | 44 | 330 | 5 | 685 | 605 | 300 | 254 | 8-18 | φ75 | 100 | ||

| DN1000 | 1230 | 1255 | 1160 | 1170 | 28xφ37 | 28xφ43 | 1112 | 40 | 50 | 410 | 5 | 735 | 670 | 300 | 254 | 8-18 | φ80 | 100 | |

| DN1200 | 1455 | 1485 | 1380 | 1390 | 32xφ40 | 32xφ49 | 1328 | 45 | 57 | 470 | 5 | 917 | 780 | 350 | 298 | 8-22 | φ90 | 100 | |

Manufacture Process of Butterfly Valve

Certificates of Zfa Valve

WRAS

CE

ISO 9001

EAC Russia