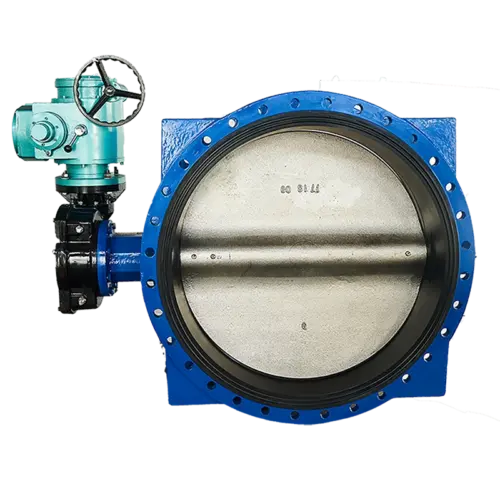

Ductile Iron/WCB Double Eccentric Butterfly Valve

Basic Info of Two Offset Butterfly Valve

- The double eccentric flange butterfly valve is controlled by worm gear. The outstanding features are quick opening and closing. The option is an electric actuator or pneumatic actuator.

- The double eccentric design keeps the contact surface between the valve seat and the valve plate at one point, effectively avoiding friction and wear between the valve seat and the valve plate. Thereby, it provided excellent sealing performance and prevented medium leakage.

- The valve body and plate of the double eccentric flange butterfly valve can be made of corrosion-resistant materials. They can adapt to the requirements of various corrosive media.

- The center of the valve stem deviates from the center of the valve and the center line of the pipeline, reducing friction during operation. The valve disc can be separated from the valve seat after rotating a certain angle, extending their service life.

- The flanged double eccentric butterfly valve adopts a mechatronics design. The electric actuator can monitor the position and status of the valve in real time, and has automatic protection and alarm functions, which improves the reliability and safety of the system.

Double Eccentric Butterfly Valve Parts

| Parts | Ductile Iron type | WCB type | Stainless Steel Type | Duplex Stainless Steel Type |

|---|---|---|---|---|

| Body | Cast Iron(GG25) Ductile Iron(GGG40/50) |

A216 A217 |

SS304/ CF8 SS316/CF8M SS304L/CF3 SS316L/CF3M |

2205 2507 1.4529 |

| Disc | Ductile Iron Stainless Steel Duplex Stainless Steel |

SS304/ CF8 SS316/CF8M SS304L/CF3 SS316L/CF3M 2205 2507 1.4529 |

2205 2507 1.4529 |

|

| Seat | NBR, EPDM, Viton, Hypalon, Silicon, PFA | |||

| Stem | SS416, SS431, SS304, SS316, Duplex Stainless Steel, Monel | Duplex Stainless Steel, Monel | ||

| Actuator | Worm Gear, Electric, Pneumatic | |||

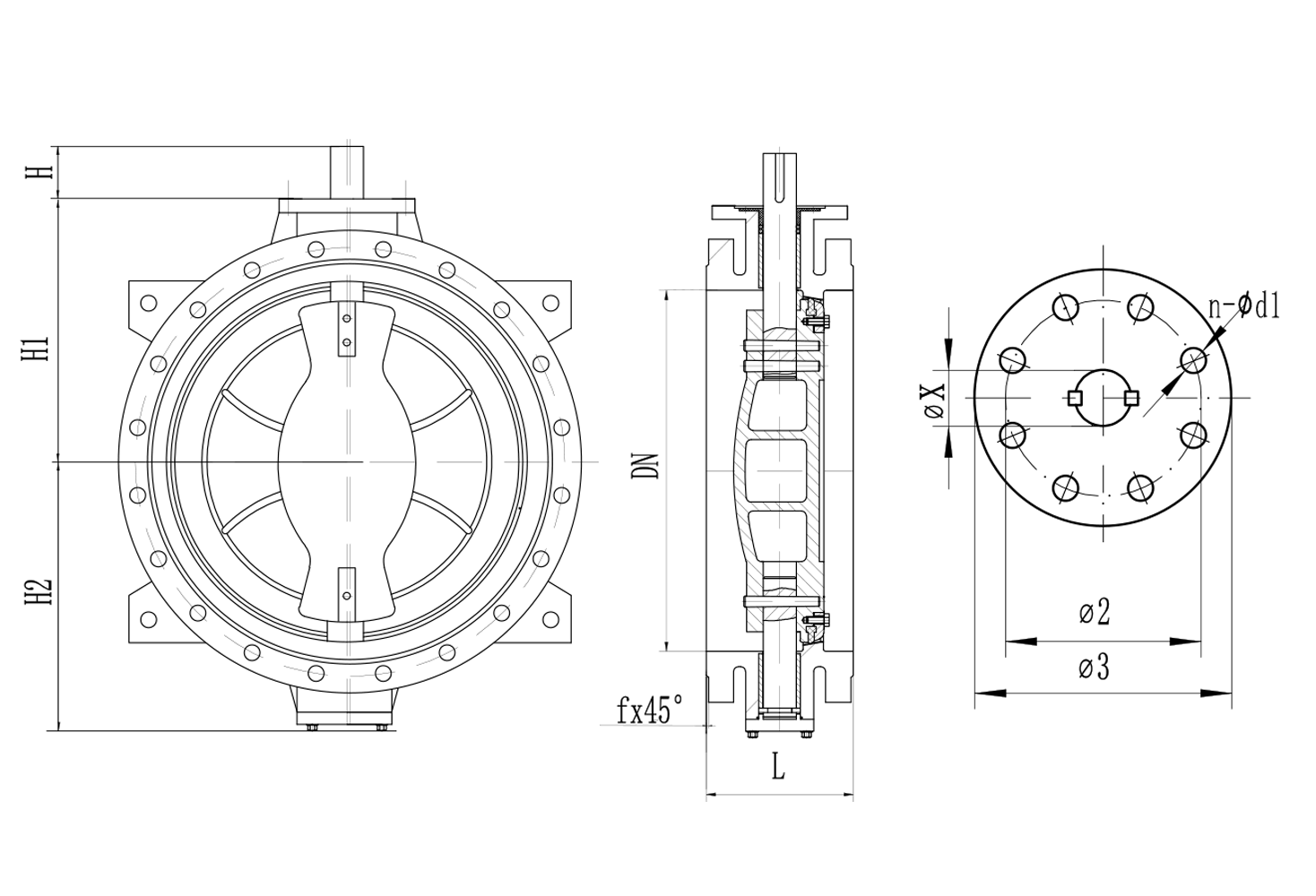

Paraments of Double Eccentric Butterfly Valve

| SIZE | H1 | H2 | L | f | ø2 | ø3 | n-ød1 | øX |

|---|---|---|---|---|---|---|---|---|

| DN100 | 178 | 123 | 190 | 3 | 70.0 | 90.00 | 4-10 | 20 |

| DN150 | 217 | 162 | 210 | 3 | 102.0 | 125.00 | 4-12 | 20 |

| DN200 | 250 | 175 | 230 | 3 | 102.0 | 125.00 | 4-12 | 25 |

| DN250 | 281 | 206 | 250 | 3 | 102.00 | 125.00 | 4-12 | 30 |

| DN300 | 306 | 246 | 270 | 4 | 125.00 | 150.00 | 4-14 | 34 |

| DN350 | 334 | 284 | 290 | 4 | 140.0 | 175.00 | 4-18 | 33 |

| DN400 | 374 | 304 | 310 | 4 | 140.0 | 175.00 | 4-18 | 41 |

| DN500 | 433 | 375 | 350 | 4 | 165.0 | 210.00 | 4-22 | 51 |

| DN600 | 493 | 436 | 390 | 5 | 165.0 | 210.00 | 4-22 | 51 |

| DN800 | 581 | 574 | 470 | 5 | 254.0 | 300.00 | 4-18 | 85 |

| DN900 | 692 | 606 | 510 | 5 | 254.0 | 300.00 | 4-18 | 85 |

| DN1000 | 722 | 685 | 550 | 5 | 254.0 | 300.00 | 8-18 | 85 |

| DN1200 | 845 | 796 | 630 | 5 | 298.0 | 350.00 | 8-22 | 105 |

Manufacture Process

Certificates of Zfa Valve

WRAS

CE

ISO 9001

EAC Russia