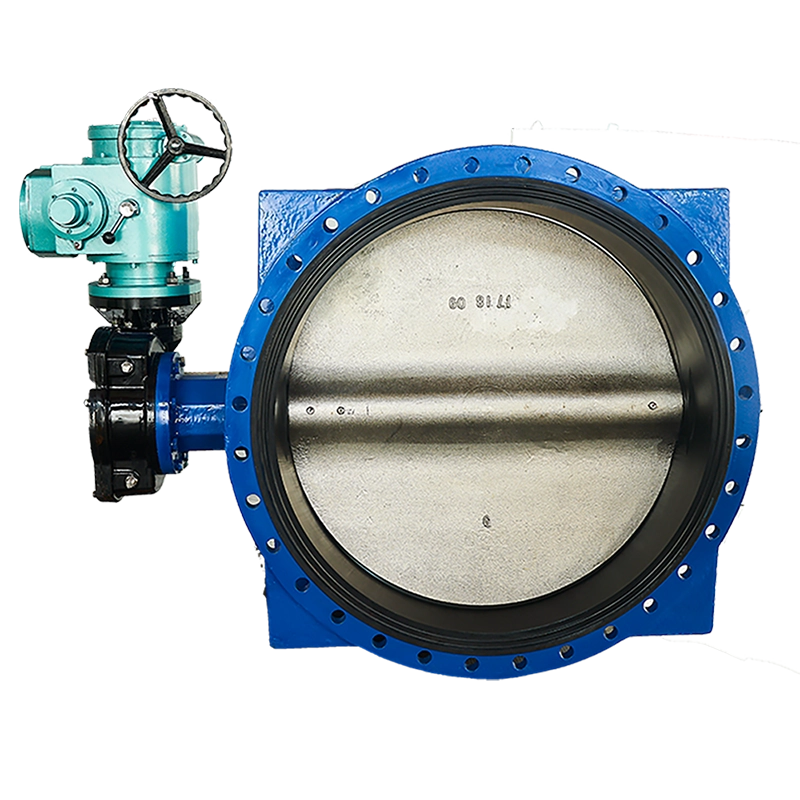

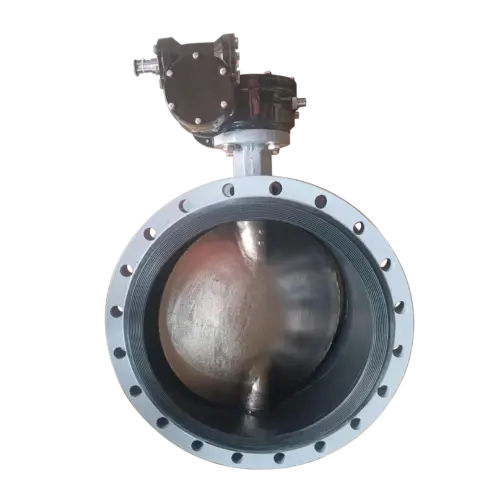

Wholesale Electric Double Flanged Butterfly Valve

Basic Info

- Reliable sealing: The valve is designed with a double-flanged configuration that ensures a tight and reliable seal in both directions, preventing any leakage of fluids or gases.

- Easy installation and maintenance: The double flange design allows for easy installation and maintenance of the valve, with the ability to mount it between two flanges using standard bolts and gaskets.

- Excellent flow control: The butterfly valve design offers excellent flow control capabilities, allowing for precise adjustments of the flow rate and an efficient regulation of the fluid or gas flow.

- High durability: The valve is constructed from high-quality materials such as cast iron, stainless steel, or ductile iron, providing excellent resistance to corrosion, wear, and pressure, ensuring a long service life.

- Versatile application: The double flanged butterfly valve is suitable for a wide range of applications including water supply systems, wastewater treatment plants, HVAC systems, and industrial processes.

- Cost-effective: Compared to other types of valves, the double flanged butterfly valve is generally more cost-effective due to its simple design, easy installation, and low maintenance requirements, making it a popular choice for various industries.

When using electric center line flange butterfly valve, you need to pay attention to the following points:

- Select the appropriate motor type and power, and determine the motor speed and torque according to actual pipeline requirements;

- When installing, ensure that the connection between the valve and flange is firm to prevent leakage;

- The control signal of the valve can be operated through manual control device, remote control device or automatic control system;

- Regularly inspect and maintain valves to ensure their normal operation and stable performance.

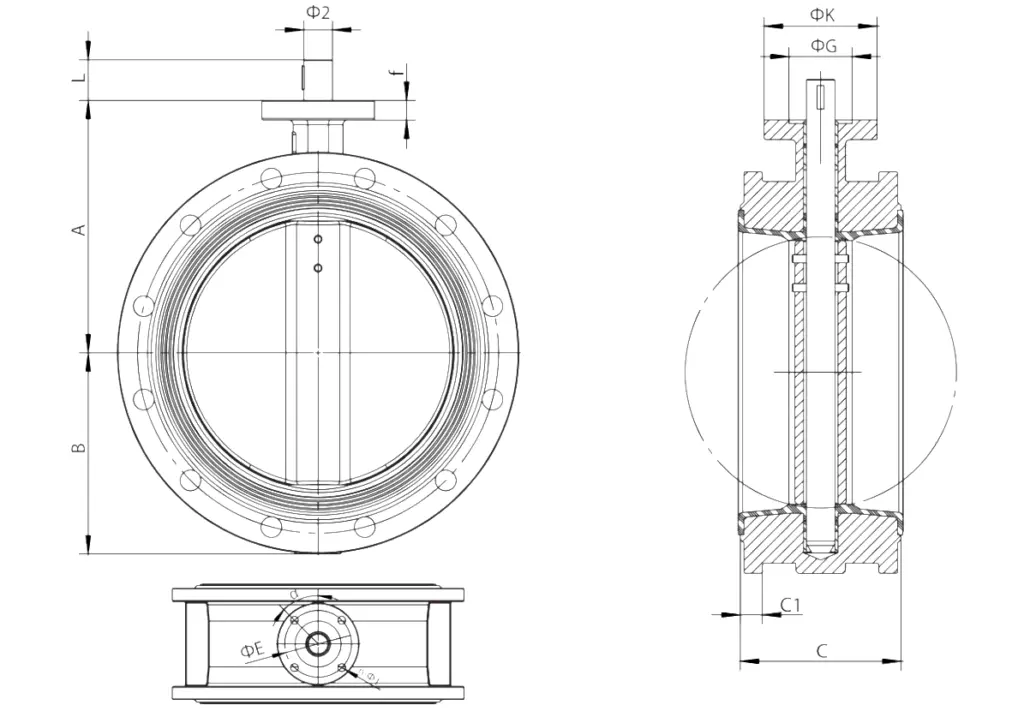

| Size & Pressure Rating & Standard | |

| Size | DN40-DN1200 |

| Pressure Rating | PN10, PN16, CL150, JIS 5K, JIS 10K |

| Face to Face STD | API609, BS5155, DIN3202, ISO5752 |

| Connection STD | PN6, PN10, PN16, PN25, 150LB, JIS5K, 10K, 16K, GOST33259 |

| Upper Flange STD | ISO 5211 |

| Material | |

| Body | Cast Iron(GG25), Ductile Iron(GGG40/50), Carbon Steel(WCB A216), Stainless Steel(SS304/SS316/SS304L/SS316L) , Duplex Stainless Steel(2507/1.4529), Bronze, Aluminium Alloy. |

| Disc | DI+Ni, Carbon Steel(WCB A216), Stainless Steel(SS304/SS316/SS304L/SS316L) , Duplex Stainless Steel(2507/1.4529), Bronze, DI/WCB/SS coated with Epoxy Painting/Nylon/EPDM/NBR/PTFE/PFA |

| Stem/Shaft | SS416, SS431, SS304, SS316, Duplex Stainless Steel, Monel |

| Seat | NBR, EPDM/REPDM, PTFE/RPTFE, Viton, Neoprene, Hypalon, Silicon, PFA |

| Bushing | PTFE, Bronze |

| O Ring | NBR, EPDM, FKM |

| Actuator | Hand Lever, Gear Box, Electric Actuator, Pneumatic Actuator |

Paraments

| DN | L | L1 | D | D1 | H | H1 | b | n-ød | |||

| mm | inch | PN1.0MPa | PN1.6MPa | PN1.0MPa | PN1.6MPa | ||||||

| 50 | 2″ | 108 | 180 | 125 | 125 | 150 | 326 | 83 | 20 | 4-ø18 | 4-ø18 |

| 65 | 21/2″ | 112 | 180 | 145 | 145 | 165 | 344 | 93 | 20 | 4-ø18 | 4-ø18 |

| 80 | 3″ | 114 | 180 | 160 | 160 | 200 | 363 | 100 | 22 | 4-ø18 | 8-ø18 |

| 100 | 4″ | 127 | 180 | 180 | 180 | 220 | 396 | 114 | 22 | 8-ø18 | 8-ø18 |

| 125 | 5″ | 140 | 180 | 210 | 210 | 250 | 421 | 125 | 24 | 8-ø18 | 8-ø18 |

| 150 | 6″ | 140 | 180 | 240 | 240 | 280 | 453 | 143 | 24 | 8-ø23 | 8-ø23 |

| 200 | 8″ | 152 | 270 | 295 | 295 | 335 | 578 | 170 | 26 | 8-ø23 | 12-ø23 |

| 250 | 10″ | 165 | 270 | 350 | 355 | 405 | 638 | 198 | 26 | 12-ø23 | 12-ø28 |

| 300 | 12″ | 178 | 380 | 400 | 410 | 455 | 731 | 223 | 32 | 12-ø23 | 12-ø28 |

| 350 | 14″ | 190 | 380 | 460 | 470 | 525 | 783 | 270 | 36 | 16-ø23 | 16-ø28 |

| 400 | 16″ | 216 | 450 | 515 | 525 | 580 | 888 | 300 | 38 | 16-ø28 | 16-ø31 |

| 450 | 18″ | 222 | 480 | 565 | 585 | 640 | 958 | 340 | 40 | 20-ø28 | 20-ø31 |

| 500 | 20″ | 229 | 480 | 620 | 650 | 705 | 1005 | 355 | 42 | 20-ø28 | 20-ø34 |

| 600 | 24″ | 267 | 480 | 725 | 770 | 825 | 1128 | 410 | 48 | 20-ø30 | 20-ø36 |

| 700 | 28″ | 292 | 640 | 840 | 840 | 920 | 1476 | 478 | 53 | 24-ø30 | 24-ø36 |

| 800 | 32″ | 318 | 640 | 950 | 950 | 1020 | 1533 | 525 | 58 | 24-ø33 | 24-ø39 |

| 900 | 36″ | 330 | 750 | 1050 | 1050 | 1120 | 1655 | 585 | 65 | 28-ø33 | 28-ø39 |

| 1000 | 40″ | 410 | 850 | 1160 | 1170 | 1340 | 1765 | 640 | 76 | 28-ø36 | 28-ø42 |

| 1200 | 48″ | 470 | 850 | 1380 | 1390 | 1560 | 1995 | 755 | 85 | 32-ø39 | 32-ø48 |

| 1400 | 56″ | 530 | 1000 | 1590 | 1590 | 1760 | 2310 | 910 | 103 | 36-ø42 | 36-ø48 |

| 1600 | 64″ | 600 | 1000 | 1820 | 1820 | 1970 | 2595 | 1030 | 123 | 40-ø48 | 40-ø56 |

| 1800 | 72″ | 697 | 1100 | 2020 | 2020 | 2180 | 2810 | 1140 | 135 | 44-ø48 | 44-ø56 |

| 2000 | 80″ | 760 | 1100 | 2230 | 2230 | 2345 | 3100 | 1250 | 145 | 48-ø48 | 48-ø56 |

Manufacture Process

Certificates

WRAS

CE

ISO 9001