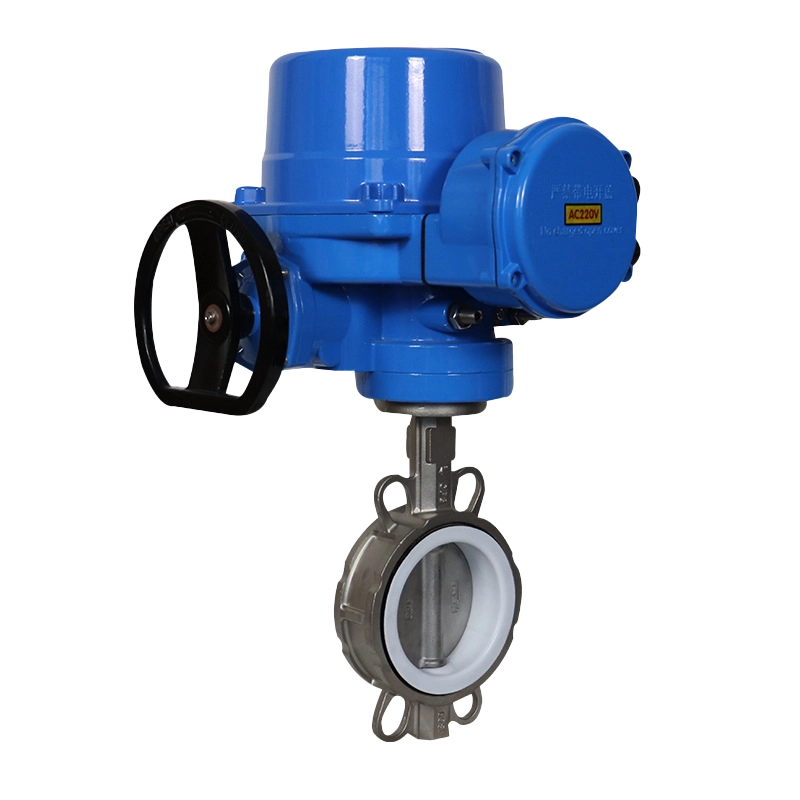

PTFE Seat Electric Wafer Butterfly Valve

Basic Info of PTFE Electric Wafer Butterfly Valve

Compare to the EPDM Seat butterfly valve, the PTFE Electric wafer butterfly valve has some more advantages.

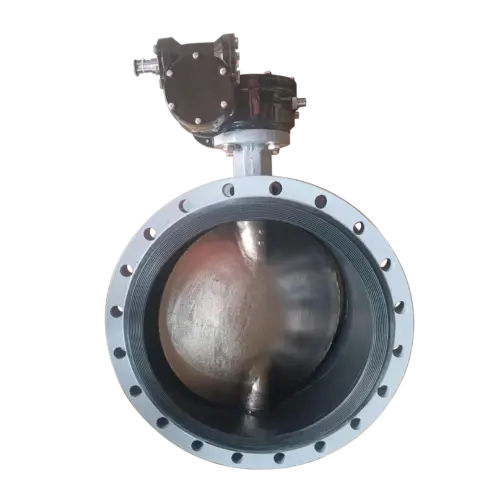

- Corrosion resistance: PTFE has excellent corrosion resistance to various corrosive liquids, including strong acids, strong alkalis, etc.

- Temperature Range: PTFE can withstand higher temperatures than EPDM, while It has a temperature range of approximately -250°C to +260°C (-418°F to +500°F)..

- Versatility: PTFE is also called “Plastic King” in China, so it is suitable for different types of media, whether it is corrosive or non-corrosive fluid.

- Low Friction: PTFE has a low coefficient of friction, reducing wear on valve components, as a result, it can increase service life and reduce maintenance.

- Universal Sealing Material: PTFE is a universal sealing material, as it is compatible with various flanges and gaskets.

- Electric Actuator: eliminates the need for manual adjustment and provides precise control over the position and flow rate of PTFE electric wafer butterfly valve.

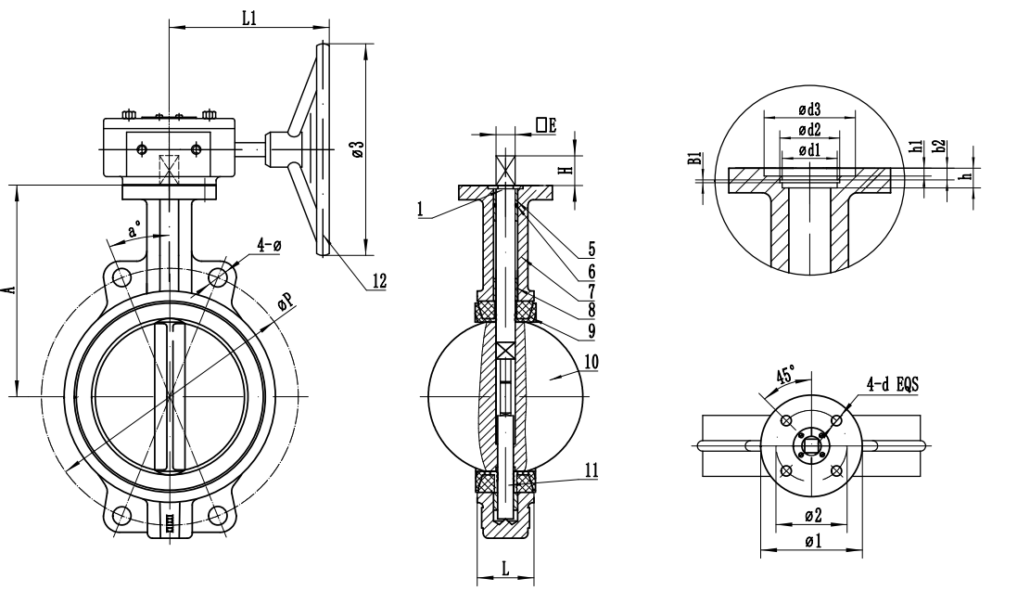

Paraments

| DN | A | B | C | D | L | H | D1 | n-ø | K | E | n1-ø1 | ø2 | |

| mm | inch | ||||||||||||

| 50 | 2″ | 161 | 80 | 42 | 52.9 | 32 | 84.84 | 120 | 4-ø23 | 77 | 57.15 | 4-ø6.7 | 12.6 |

| 65 | 2.5″ | 175 | 89 | 44.7 | 64.5 | 32 | 96.2 | 136.2 | 4-ø26.5 | 77 | 57.15 | 4-ø6.7 | 12.6 |

| 80 | 3″ | 181 | 95 | 45.2 | 78.8 | 32 | 61.23 | 160 | 8-ø18 | 77 | 57.15 | 4-ø6.7 | 12.6 |

| 100 | 4″ | 200 | 114 | 52.1 | 104 | 32 | 70.80 | 185 | 4-ø24.5 | 92 | 69.85 | 4-ø10.3 | 15.77 |

| 125 | 5″ | 213 | 127 | 54.4 | 123.3 | 32 | 82.28 | 215 | 4-ø23 | 92 | 69.85 | 4-ø10.3 | 18.92 |

| 150 | 6″ | 226 | 139 | 55.8 | 155.6 | 32 | 91.08 | 238 | 4-ø25 | 92 | 69.85 | 4-ø10.3 | 18.92 |

| 200 | 8″ | 260 | 175 | 60.6 | 202.5 | 45 | 112.89/76.35 | 295 | 4-ø25 | 115 | 88.9 | 4-ø14.3 | 22.1 |

| /4-ø23 | |||||||||||||

| 250 | 10″ | 292 | 203 | 65.6 | 250.5 | 45 | 92.40 | 357 | 4-ø29 | 115 | 88.9 | 4-ø14.3 | 28.45 |

| 300 | 12″ | 337 | 242 | 76.9 | 301.6 | 45 | 105.34 | 407 | 4-ø29 | 140 | 107.95 | 4-ø14.3 | 31.6 |

| 350 | 14″ | 368 | 267 | 76.5 | 333.3 | 45 | 91.11 | 467 | 4-ø30 | 140 | 107.95 | 4-ø14.3 | 31.6 |

| 400 | 16″ | 400 | 309 | 86.5 | 389.6 | 51.2 | 100.47/102.42 | 515 | 4-ø26 | 197 | 158.75 | 4-ø20.6 | 33.15 |

| /72 | /525 | /4-ø30 | |||||||||||

| 450 | 18″ | 422 | 328 | 105.6 | 440.51 | 51.2 | 88.39/91.51 | 565 | 4-ø26 | 197 | 158.75 | 4-ø20.6 | 38 |

| /72 | /585 | /4-ø30 | |||||||||||

| 500 | 20″ | 480 | 361 | 131.8 | 491.6 | 64.2 | 96.99/101.68 | 620 | 4-ø26 | 197 | 158.75 | 4-ø20.6 | 41.15 |

| /82 | /650 | /4-ø33 | |||||||||||

| 600 | 24″ | 562 | 459 | 152 | 592.5 | 70.2 | 113.42/120.46 | 725 | 20-ø30 | 276 | 215.9 | 4-ø22.2 | 50.65 |

| /82 | /770 | /20-ø36 | |||||||||||

| 700 | 28″ | 624 | 520 | 163 | 695 | 66 | 109.65 | 840 | 24-ø30 | 300 | 254 | 8-ø18 | 55/63.35 |

| /82 | /20-ø36 | ||||||||||||

| 800 | 32″ | 672 | 591 | 188 | 794.7 | 66 | 124 | 950 | 24-ø33 | 300 | 254 | 8-ø18 | 55/63.35 |

| /82 | /24-ø39 | ||||||||||||

| 900 | 36″ | 720 | 656 | 203 | 864.7 | 118 | 117.57 | 1050 | 24-ø33 | 300 | 254 | 8-ø18 | 75 |

| 1000 | 40″ | 800 | 721 | 216 | 965 | 142 | 129.89 | 1160 | 24-ø36 | 300 | 254 | 8-ø18 | 85 |

Manufacture Process

Certificates

WRAS

CE

ISO 9001

EAC Russia