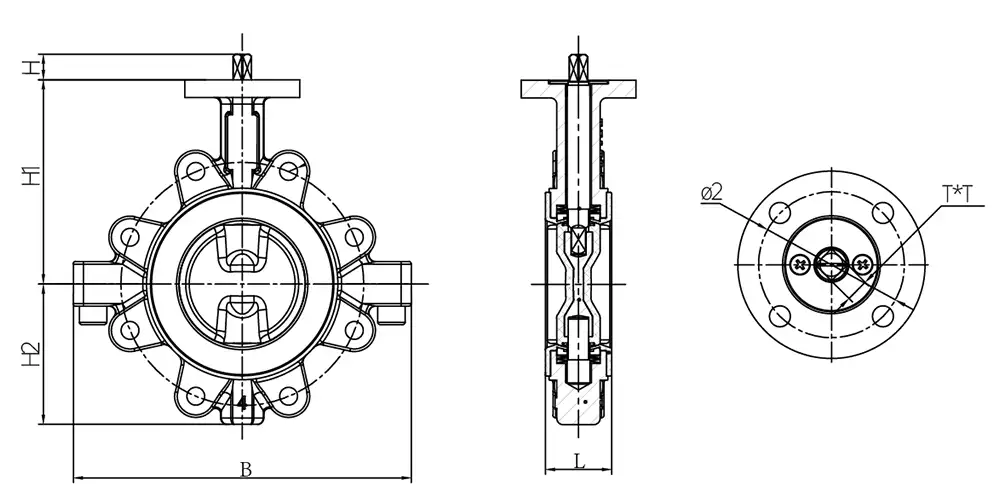

PTFE Lined Seat PFA Paint Disc Split Body Lug Butterfly Valve

Basic Info

- Corrosion resistance: By using fluorine-lined material in the center line, the valve body can be effectively prevented from being corroded and the service life of the valve is increased.

- Lug design: Lug butterfly valve has a lug design, which can reduce the erosion of the valve seat and sealing ring by the medium, and improve the service life and reliability.

- Detachable design: The Split type Lug Butterfly Valve Body is designed to be easily disassembled, making installation, maintenance and replacement simpler and more convenient.

- The split Body Lug butterfly valve is equipped with two shafts, providing improved disc alignment, and it can reduce wear on the valve components.

| Parts | Ductile Iron type | WCB type | Stainless Steel Type | Duplex Stainless Steel Type |

|---|---|---|---|---|

| Body | Cast Iron(GG25) Ductile Iron(GGG40/50) |

A216 A217 A105(forged) |

SS304/ CF8 SS316/CF8M SS304L/CF3 SS316L/CF3M |

2205 2507 1.4529 |

| Disc | Ductile Iron with Ni coated Ductile Iron with nylon coated Ductile Iron with PTFE/EPDM lined Stainless Steel Duplex Stainless Steel Bronze |

SS304/ CF8 SS316/CF8M SS304L/CF3 SS316L/CF3M 2205 2507 1.4529 |

2205 2507 1.4529 |

|

| Seat | NBR, EPDM, PTFE, Viton, Hypalon, Silicon, PFA | |||

| Stem | SS416, SS431, SS304, SS316, Duplex Stainless Steel, Monel | Duplex Stainless Steel, Monel | ||

| Actuator | Hand Lever, Worm Gear, Electric, Pneumatic | |||

Paraments of Split Lug Butterfly Valve

| DN | L | E | F | Z | K | H |

|---|---|---|---|---|---|---|

| 50 | 43 | 134 | 68 | 50 | 9 | 25 |

| 65 | 46 | 145 | 75 | 50 | 9 | 25 |

| 80 | 46 | 150 | 85 | 50 | 9 | 25 |

| 100 | 52 | 160 | 95 | 70 | 11 | 25 |

| 125 | 56 | 178 | 115 | 70 | 14 | 25 |

| 150 | 56 | 197 | 130 | 70 | 14 | 25 |

| 200 | 60 | 239 | 160 | 102 | 17 | 30 |

| 250 | 68 | 278 | 200 | 102 | 22 | 30 |

| 300 | 78 | 315 | 230 | 125 | 22 | 30 |

Manufacture Process of Lug Butterfly Valve

Certificates of Zfa Valve

WRAS

CE

ISO 9001

EAC Russia