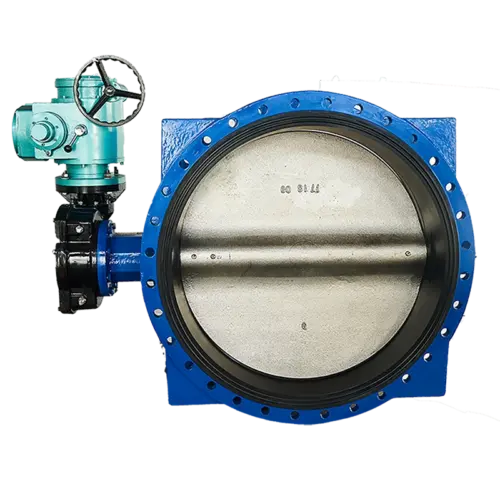

Double Flanged Replaceable Seat Stainless Steel Butterfly Valve with Lever

Basic Info of Flanged Stainless Steel Butterfly Valve

| ITEM | Standard |

| Design | EN593 | API609 |

| Face to Face | EN558 | ISO5752 | API608 | BS5155-4 |

| Top Flange | ISO5211 |

| Flange Drilling | PN6 | PN10 | PN16 | ASME B16.5 CL150 | JIS 10K |

| Pressure Rating | PN6 | PN10 | PN16 | PN25 | CL150 | JIS 10K |

| Tightness Test | ISO5208 | API598 | EN12266-1 |

- CF8 of stainless steel butterfly valve has excellent corrosion resistance in environments containing corrosive medium.

- Replaceable Seat Double Flanged Butterfly Valve adopts a replaceable seat, so that it can be easily replaced without replacing the entire valve assembly, saving maintenance and replacement costs.

- Efficient Flow Control: The butterfly plate inside the valve can rotate 90 degrees to fully open or close the valve. This design provides lower flow resistance, allowing for higher flow rates and more efficient fluid control.

- Simple Installation: The Double Flanged Butterfly Valve makes installation of the valve easier and faster, it can reduce possible problems and delays during installation.

Paraments of Stainless Steel Butterfly Valve

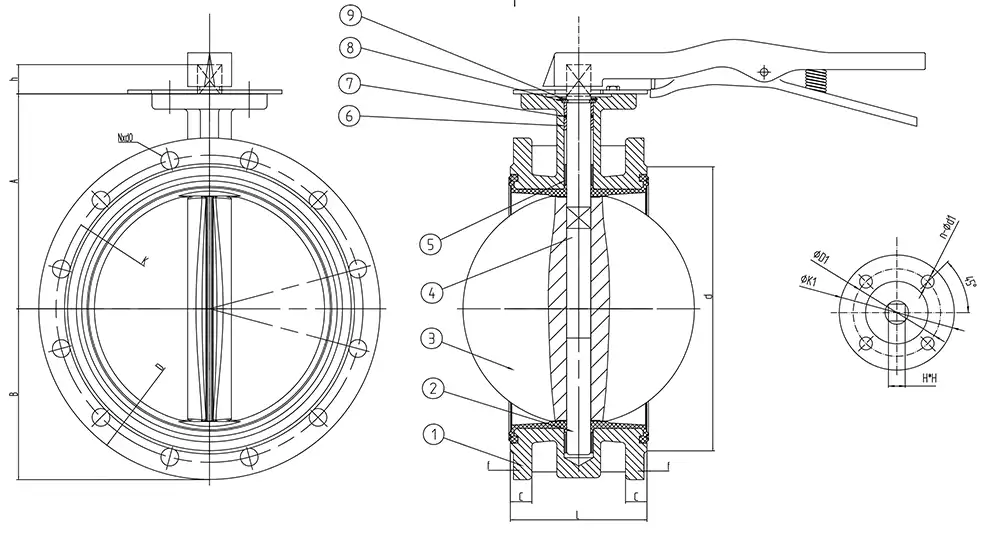

Lever op ss butterfly valve

| DN | D | K | Nxd0 | d | C | L | f | A | B | K1 | 01 | n-d1 | HXH | h | |||||

| PN10 | PN16 | PN10 | PN16 | PN10 | PN16 | PN10 | PN16 | PN10 | PN16 | ||||||||||

| DN50 | 165 | 125 | 4xφ18 | 99 | 19 | 108 | 3 | 139 | 80 | 65 | 50 | 4-8 | 11X11 | 30 | |||||

| DN65 | 185 | 145 | 4xφ18 | 118 | 19 | 112 | 3 | 146 | 89 | 65 | 50 | 4-8 | 11X11 | 30 | |||||

| DN80 | 200 | 160 | 8xφ18 | 132 | 19 | 114 | 3 | 150 | 95 | 65 | 50 | 4-8 | 11X11 | 30 | |||||

| DN100 | 220 | 180 | 8xφ18 | 156 | 19 | 127 | 3 | 177 | 114 | 90 | 70 | 4-10 | 11X11 | 30 | |||||

| DN125 | 250 | 210 | 8xφ18 | 184 | 19 | 140 | 3 | 178 | 125 | 90 | 70 | 4-10 | 14X14 | 30 | |||||

| DN150 | 285 | 240 | 8xφ22 | 211 | 20 | 140 | 3 | 201 | 139 | 90 | 70 | 4-10 | 14X14 | 30 | |||||

| DN200 | 340 | 295 | 8xφ22 | 12xφ22 | 270 | 20 | 152 | 3 | 230 | 170 | 125 | 102 | 4-12 | 17X17 | 35 | ||||

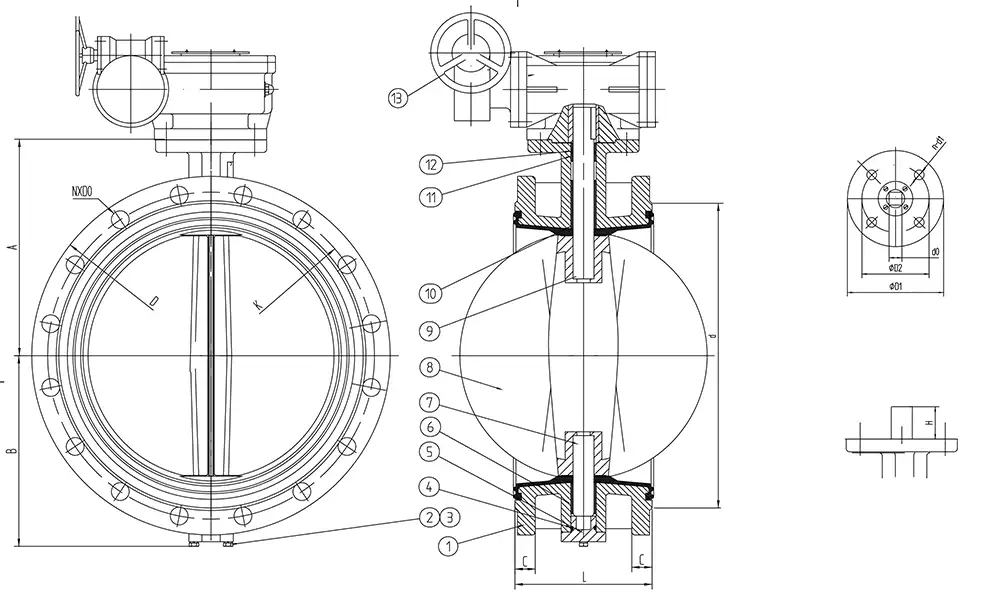

worm gear op ss butterfly valve

| DN | 0 | K | Nxd0 | d | C | L | f | A | B | 01 | 02 | 0-d1 | d0 | H | |||||

| PN10 | PN16 | PN10 | PN16 | PN10 | PN16 | PN10 | PN16 | PN10 | PN16 | ||||||||||

| DN250 | 395 | 405 | 350 | 355 | 12xφ23 | 12xφ28 | 319 | 22 | 165 | 3 | 266 | 198 | 125 | 102 | 4-12 | 22X22 | 35 | ||

| DN300 | 445 | 460 | 400 | 410 | 12xφ23 | 12xφ28 | 370 | 24.5 | 178 | 4 | 298 | 223 | 125 | 102 | 4-12 | 22X22 | 35 | ||

| DN350 | 505 | 520 | 460 | 470 | 16xφ23 | 16xφ28 | 429 | 24.5 | 26.5 | 190 | 4 | 310 | 254 | 150 | 125 | 4-14 | 22X22 | 35 | |

| DN400 | 565 | 580 | 515 | 525 | 16xφ28 | 16xφ31 | 480 | 245 | 28 | 216 | 4 | 340 | 278 | 175 | 140 | 4-18 | 27X27 | 50 | |

| DN500 | 670 | 715 | 620 | 650 | 20xφ28 | 20xφ34 | 582 | 609 | 265 | 32 | 229 | 4 | 430 | 348 | 175 | 140 | 4-18 | 36X36 | 50 |

| DN600 | 780 | 840 | 725 | 770 | 20xφ31 | 20xφ37 | 682 | 720 | 30 | 36 | 267 | 5 | 500 | 410 | 210 | 165 | 4-22 | 36X36 | 60 |

| DN700 | 895 | 910 | 840 | 24xφ31 | 24xφ37 | 794 | 325 | 395 | 292 | 5 | 560 | 480 | 300 | 254 | 8-18 | φ6335 | 80 | ||

| DN800 | 1015 | 1025 | 950 | 24xφ34 | 24xφ40 | 901 | 35 | 41 | 318 | 5 | 620 | 530 | 300 | 254 | 8-18 | φ6335 | 80 | ||

| DN900 | 1115 | 1125 | 1050 | 28xφ34 | 28xφ40 | 1001 | 36 | 44 | 330 | 5 | 685 | 605 | 300 | 254 | 8-18 | φ75 | 100 | ||

| DN1000 | 1230 | 1255 | 1160 | 1170 | 28xφ37 | 28xφ43 | 1112 | 40 | 50 | 410 | 5 | 735 | 670 | 300 | 254 | 8-18 | φ80 | 100 | |

| DN1200 | 1455 | 1485 | 1380 | 1390 | 32xφ40 | 32xφ49 | 1328 | 45 | 57 | 470 | 5 | 917 | 780 | 350 | 298 | 8-22 | φ90 | 100 | |

Manufacture Process of Flanged Stainless Steel Butterfly Valve

Certificates of Zfa Valve

WRAS

CE

ISO 9001

EAC Russia