Wafer Soft Seat EPDM Lined Disc Butterfly Valve

Features of EPDM Lined Disc Butterfly Valve

Fully Epdm lined butterfly valve refers to internal surfaces of the valve, including the disc and the body, are completely covered or lined with EPDM rubber.

- Advanced sealing: EPDM Lined Disc Butterfly Valve can effectively prevent leakage and ensure that fluid will not leak or penetrate into the valve structure, improving the safety and efficiency of the system.

- Corrosion resistance: The outer layer of the EPDM Lined Butterfly Valve disc is coated with EPDM material. It can withstand the erosion of various chemicals and corrosive media.

- Replaceable seat: soft back seat EPDM seat is replacable, when it ages or breaks can save costs.

- Wide application: EPDM fully lined butterfly valve is suitable for fluid control and treatment in various fields, such as water treatment, chemical industry, petroleum, pharmaceutical, food, etc.

Basic Info of EPDM Lined Disc Butterfly Valve

Material

| Part Name | Material/Method |

| Body | Ductile Iron, Casting Iron, WCB, LCB/LCC, Stainless Steel, Duplex Stainless Steel, Aluminium Bronze |

| Disc | Ductile Iron(Coated/Lined), WCB, LCB/LCC, Stainless Steel, Duplex Stainless Steel, Aluminium Bronze |

| Seat | PFA, Rubber(EPDM/NBR/VITON), Nature Rubber, Silicon Rubber, PU, HNBR, Hypalon |

| Stem | 304, 316, 420(2Cr13), 431, 1.4462, 17-4PH, Monel |

| Actuator | Handlever, Worm Gear, Electric, Pneumatic |

Technical Data

| ITEM | Standard |

| Design | EN593 | API609 |

| Face to Face | EN558 | ISO5752 | API608 | BS5155-4 |

| Top Flange | ISO5211 |

| Flange Drilling | PN6 | PN10 | PN16 | ASME B16.5 CL150 | JIS 10K |

| Pressure Rating | PN6 | PN10 | PN16 | PN25 | CL150 | JIS 10K |

| Tightness Test | ISO5208 | API598 | EN12266-1 |

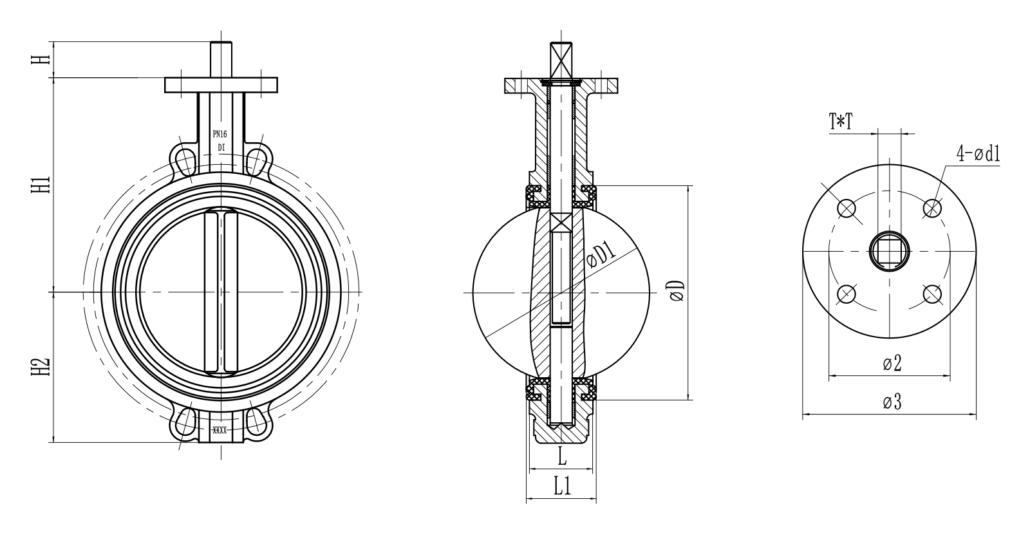

Paraments of EPDM Lined Disc Butterfly Valve

| SIZE | øD | øD1 | L | L1 | H | H1 | H2 | ø2 | ø3 | 4-ød1 | T*T |

|---|---|---|---|---|---|---|---|---|---|---|---|

| DN25 | 55 | 33 | 26 | 29 | 30 | 122 | 48 | 50 | 65 | 7 | 11 |

| DN40 | 65 | 43.1 | 33 | 36 | 30 | 139 | 70 | 50 | 65 | 7 | 11 |

| DN50 | 82 | 53.08 | 42.5 | 46.1 | 30 | 140 | 60 | 70 | 90 | 10 | 11 |

| DN65 | 94 | 64.82 | 45.6 | 49 | 30 | 150 | 67 | 70 | 90 | 10 | 11 |

| DN80 | 111.2 | 79.04 | 45.6 | 48.4 | 30 | 160 | 87 | 70 | 90 | 10 | 11 |

| DN100 | 140 | 104.04 | 52 | 56 | 30 | 180 | 105 | 70 | 90 | 10 | 11 |

| DN125 | 166 | 123.3 | 56 | 60 | 30 | 190 | 118 | 70 | 90 | 10 | 14 |

| DN150 | 187 | 155.68 | 56 | 60 | 30 | 210 | 130 | 70 | 90 | 10 | 14 |

| DN200 | 246.8 | 201.9 | 60 | 64 | 35 | 235 | 166 | 102 | 125 | 12 | 17 |

| DN250 | 301.5 | 250.45 | 68 | 72 | 35 | 270 | 197 | 102 | 125 | 12 | 22 |

| DN300 | 352 | 301.55 | 78 | 83 | 35 | 305 | 231 | 102 | 125 | 12 | 22 |

| DN350 | 390 | 333.8 | 78 | 83 | 35 | 360 | 255 | 125 | 150 | 14 | 22 |

| DN400 | 452 | 389 | 102 | 106 | 50 | 381 | 293 | 140 | 175 | 18 | 27 |

| DN450 | 510 | 439.2 | 114 | 118 | 50 | 425 | 325 | 140 | 175 | 18 | 27 |

| DN500 | 564 | 491.4 | 127 | 132 | 50 | 470 | 363 | 140 | 175 | 18 | 36 |

| DN600 | 651 | 579 | 153 | 159 | 60 | 565 | 425 | 165 | 210 | 22 | 36 |

Manufacture Process of Butterfly Valve

Certificates

WRAS

CE

ISO 9001

EAC Russia