Triple Offset Type D Flanged Butterfly Valve

Basic Info

- Size Range: DN50-DN3000

- Temperature Range: -196°C to 800°C

- D type flange connection, there is a groove on the flange surface of D Flanged Butterfly Valve. Compared with ordinary raised face flange and flat face flange, D type is more firmly connected to the pipe.

- Triple Offset Design The triple offset d flanged butterfly valve provides a metal-to-metal or multi-layer sealing mechanism to ensure a bubble seal with minimal wear on the sealing components. This design eliminates friction between the disc and the seat during operation, reduces torque and extends the life of the valve.

- High temperature and high pressure design The triple offset butterfly valve features a metal seat, making it ideal for high temperature and high pressure applications. And, it maintains performance even in abrasive and corrosive environments.

- The butterfly valve is designed to meet fire protection standards and is suitable for environments such as refineries and chemical plants where fire protection is critical.

Standard of Triple Offset D Flanged Butterfly Valve

| ITEM | Standard |

| Design | EN593 | API609 |

| Face to Face | EN558 | ISO5752 | API608 | BS5155-4 |

| Top Flange | ISO5211 |

| Flange Drilling | PN6 | PN10 | PN16 | ASME B16.5 CL150 | JIS 10K |

| Pressure Rating | PN6 | PN10 | PN16 | PN25 | CL150 | JIS 10K |

| Tightness Test | ISO5208 | API598 | EN12266-1 |

Material of Triple Offset D Flanged Butterfly Valve

| Part Name | Material/Method |

| Body | Ductile Iron, Casting Iron, WCB, LCB/LCC, Stainless Steel, Duplex Stainless Steel, Aluminium Bronze |

| Disc | Ductile Iron(Coated/Lined), WCB, LCB/LCC, Stainless Steel, Duplex Stainless Steel, Aluminium Bronze |

| Seat | Metal+Flexible Graphite |

| Stem | 304, 316, 420(2Cr13), 431, 1.4462, 17-4PH, Monel |

| Actuator | Handlever, Worm Gear, Electric, Pneumatic |

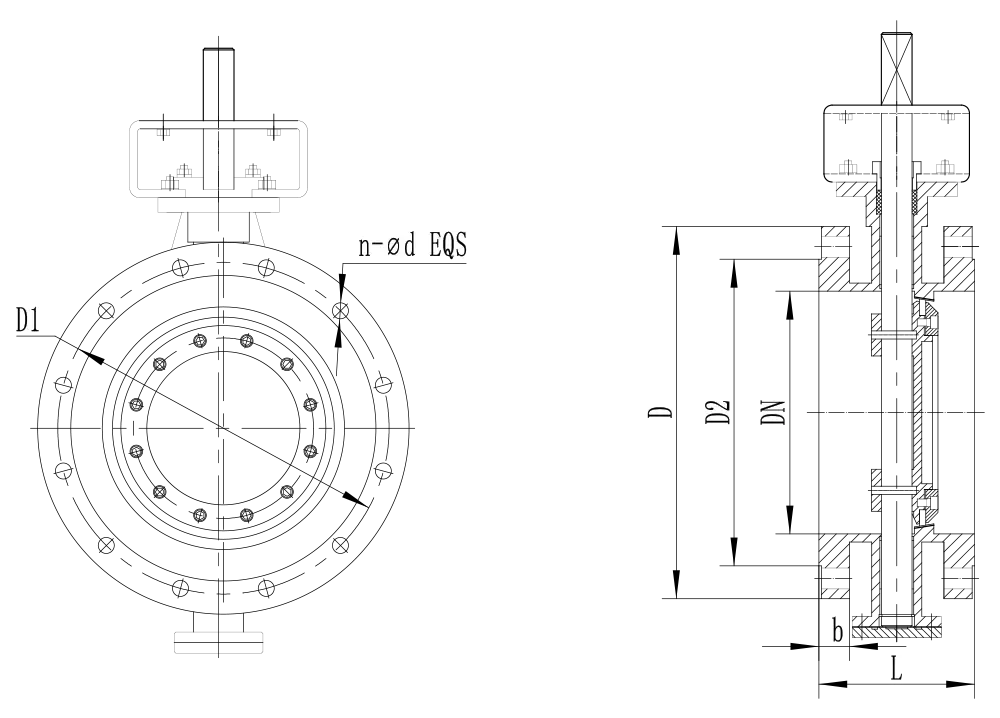

Paraments

| SIZE | PN16 | 150LB | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| D | D1 | D2 | b | n-ød | L | D | D1 | D2 | b | n-ød | L | |

| DN100 | 220 | 180 | 158 | 20 | 8-ø18 | 127±2 | 230 | 191 | 157 | 24 | 8-ø19 | 127±3.3 |

| DN125 | 250 | 210 | 188 | 22 | 8-ø18 | 140±2 | 255 | 216 | 186 | 24 | 8-ø22 | 140±3.3 |

| DN150 | 285 | 240 | 212 | 22 | 8-ø22 | 140±2 | 280 | 241 | 216 | 26 | 8-ø22 | 140±3.3 |

| DN200 | 340 | 295 | 268 | 24 | 12-ø22 | 152±2 | 345 | 299 | 270 | 29 | 8-ø22 | 152±3.3 |

| DN250 | 405 | 355 | 320 | 26 | 12-ø26 | 165±2 | 405 | 362 | 324 | 31 | 12-ø26 | 165±3.3 |

| DN300 | 460 | 410 | 378 | 28 | 12-ø26 | 178±2 | 485 | 432 | 381 | 32 | 12-ø26 | 178±3.3 |

| DN350 | 520 | 470 | 438 | 30 | 16-ø26 | 190±2 | 535 | 476 | 413 | 35 | 12-ø29 | 190±3.3 |

| DN400 | 580 | 525 | 490 | 32 | 16-ø30 | 216±2 | 595 | 540 | 470 | 37 | 16-ø29 | 216±3.3 |

| DN450 | 640 | 585 | 550 | 40 | 20-ø30 | 222±2 | 635 | 578 | 533 | 40 | 16-ø32 | 222±3.3 |

| DN500 | 715 | 650 | 610 | 44 | 20-ø33 | 229±2 | 700 | 635 | 584 | 43 | 20-ø32 | 229±3.3 |

| DN600 | 840 | 770 | 725 | 54 | 20-ø36 | 267±3 | 815 | 749 | 692 | 48 | 20-ø35 | 267±3.3 |

Manufacture Process

Certificates

WRAS

CE

ISO 9001

EAC Russia