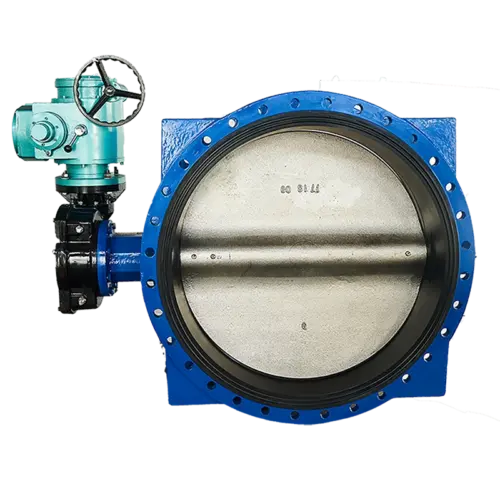

Tungsten Carbide Coated CF8 Disc Hard Back Seat Wafer Butterfly Valve

Basic Info

- After the surface of the butterfly plate is coated with tungsten carbide, wear resistance of Tungsten Carbide Butterfly Valve can be significantly improved, which is especially suitable for occasions where the medium contains solid particles or other highly abrasive fluids.

- Tungsten carbide valve plate has good corrosion resistance. Its coating effectively resists attack by acids, alkalis or other corrosive chemicals.

- Because the tungsten carbide coating significantly reduces wear and corrosion, it extends the overall life of the butterfly plate. Under the same conditions, the service life of the tungsten carbide coated butterfly plate is much longer than that of ordinary butterfly plates, reducing maintenance costs and downtime.

- The smoothness of the tungsten carbide coating can effectively prevent wear between the butterfly plate and the valve seat, so the tungsten carbide butterfly plate can maintain a stable seal even after frequent opening and closing.

Standard of Wafer Butterfly Valve

| ITEM | Standard |

| Design | EN593 | API609 |

| Face to Face | EN558 | ISO5752 | API608 | BS5155-4 |

| Top Flange | ISO5211 |

| Flange Drilling | PN6 | PN10 | PN16 | ASME B16.5 CL150 | JIS 10K |

| Pressure Rating | PN6 | PN10 | PN16 | PN25 | CL150 | JIS 10K |

| Tightness Test | ISO5208 | API598 | EN12266-1 |

Material of Wafer Butterfly Valve

| Part Name | Material/Method |

| Body | Ductile Iron, Casting Iron, WCB, LCB/LCC, Stainless Steel, Duplex Stainless Steel, Aluminium Bronze |

| Disc | Tungsten Carbide Coated CF8 |

| Seat | Rubber(EPDM/NBR/VITON), Nature Rubber, Silicon Rubber, PU, HNBR, Hypalon |

| Stem | 304, 316, 420(2Cr13), 431, 1.4462, 17-4PH, Monel |

| Actuator | Handlever, Worm Gear, Electric, Pneumatic |

Paraments

| SIZE | D1 | D2 | D3 | N×φD | α° | F | G | A | B | C | E |

| DN50(2″) | 52.6 | 100 | 120.6 | 4×19 | 45 | 52 | 266.7 | 273 | 161 | 43 | 32 |

| DN100(4″) | 104 | 156 | 190.5 | 8×19 | 22.5 | 52 | 266.7 | 346 | 200 | 52.1 | 32 |

| DN150(6″) | 155.6 | 212 | 241.3 | 8×22. | 422.5 | 52 | 266.7 | 397 | 226 | 55.8 | 32 |

| DN200(8″) | 202.4 | 264 | 298.4 | 8×22. | 422.5 | 52 | 359 | 485 | 260 | 60.6 | 45 |

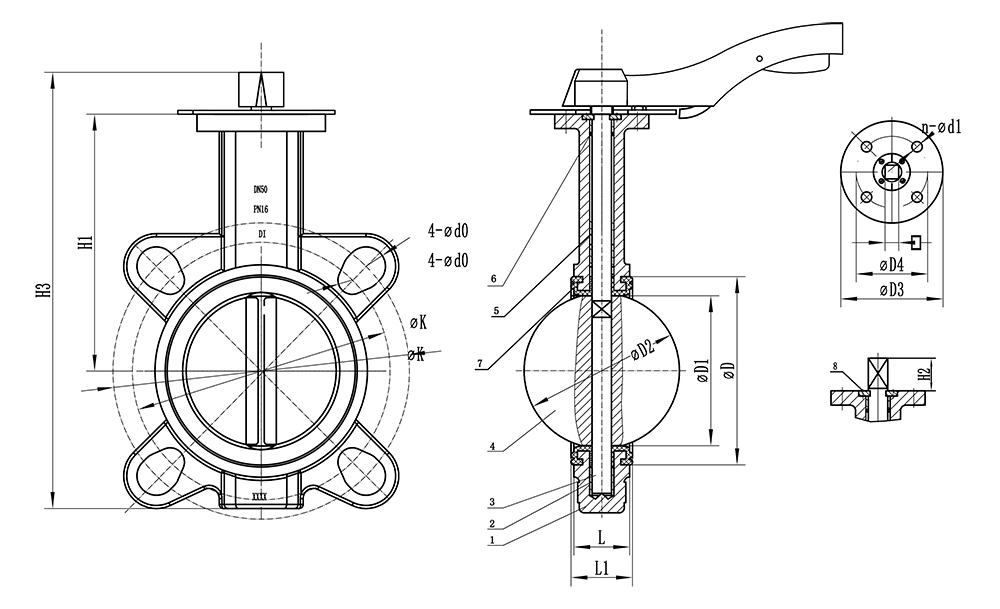

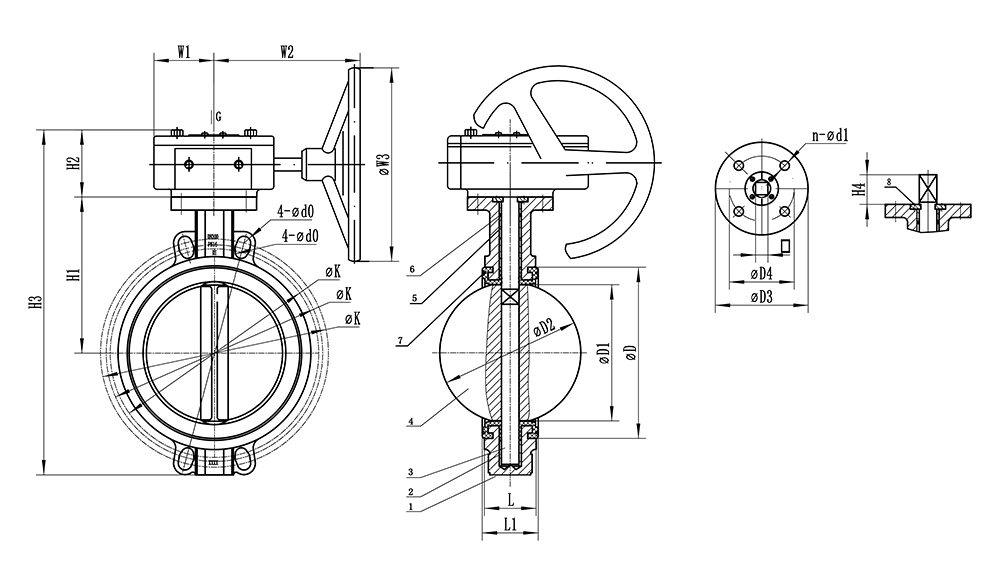

| SIZE | øK | 4-ød0 | øD | øD1 | øD2 | L | L1 | H1 | H2 | H3 | øD3 | øD4 | n-ød1 | □ | H4 | W1 | W2 | øW3 | |||||||

| PN6 | PN10 | PN16 | CL150 | PN6 | PN10 | PN16 | CL150 | ||||||||||||||||||

| DN200 | 8〞 | 280 | 295 | 295 | 298.5 | 4-ø19 | 4-ø23 | 4-ø23 | 4-ø22.3 | 246 | 194 | 202 | 60 | 64 | 235 | 86 | 487 | 125 | 102 | 4-012 | □17 | 35 | 75 | 238 | 300 |

| DN250 | 10〞 | 335 | 350 | 355 | 362 | 4-ø19 | 4-ø23 | 4-ø28 | 4-ø25.4 | 301.5 | 241 | 250 | 68 | 72 | 270 | 86 | 553 | 125 | 102 | 4-ø12 | □22 | 35 | 75 | 238 | 300 |

| DN300 | 12〞 | 395 | 400 | 410 | 431.8 | 4-ø23 | 4-ø23 | 4-ø28 | 4-ø25.4 | 352 | 290 | 301 | 78 | 83 | 310 | 118 | 658 | 25 | 102 | 4-ø12 | □22 | 35 | 81 | 227 | 300 |

| DN350 | 14〞 | 445 | 460 | 470 | 476.3 | 4-ø23 | 4-ø23 | 4-ø28 | 4-ø28.6 | 390 | 325.4 | 333.3 | 78 | 83 | 360 | 118 | 733 | 150 | 125 | 4-ø14 | □22 | 35 | 81 | 227 | 300 |

| DN400 | 16〞 | 495 | 515 | 525 | 539.8 | 4-ø23 | 4- ø 28 | 4-ø31 | 4-ø28.6 | 452 | 377 | 387 | 102 | 106 | 380 | 150 | 821 | 175 | 140 | 4-018 | □27 | 50 | 115 | 278 | 300 |

| DN500 | 20〞 | 600 | 620 | 650 | 635 | 4-ø23 | 4-ø28 | 4-ø34 | 4-ø31.8 | 564 | 480 | 491.6 | 127 | 132 | 470 | 150 | 981 | 175 | 140 | 4-ø18 | □27 | 50 | 115 | 278 | 300 |

| DN600 | 24〞 | 705 | 725 | 770 | 749.3 | 4-ø26 | 4-ø31 | 4-ø37 | 4-ø35 | 649.5 | 579.9 | 592.5 | 153 | 159 | 495 | 180 | 1120 | 210 | 165 | 4-022 | □36 | 60 | 144 | 304 | 300 |

Manufacture Process

Certificates of Zfa Valve

WRAS

CE

ISO 9001

EAC Russia