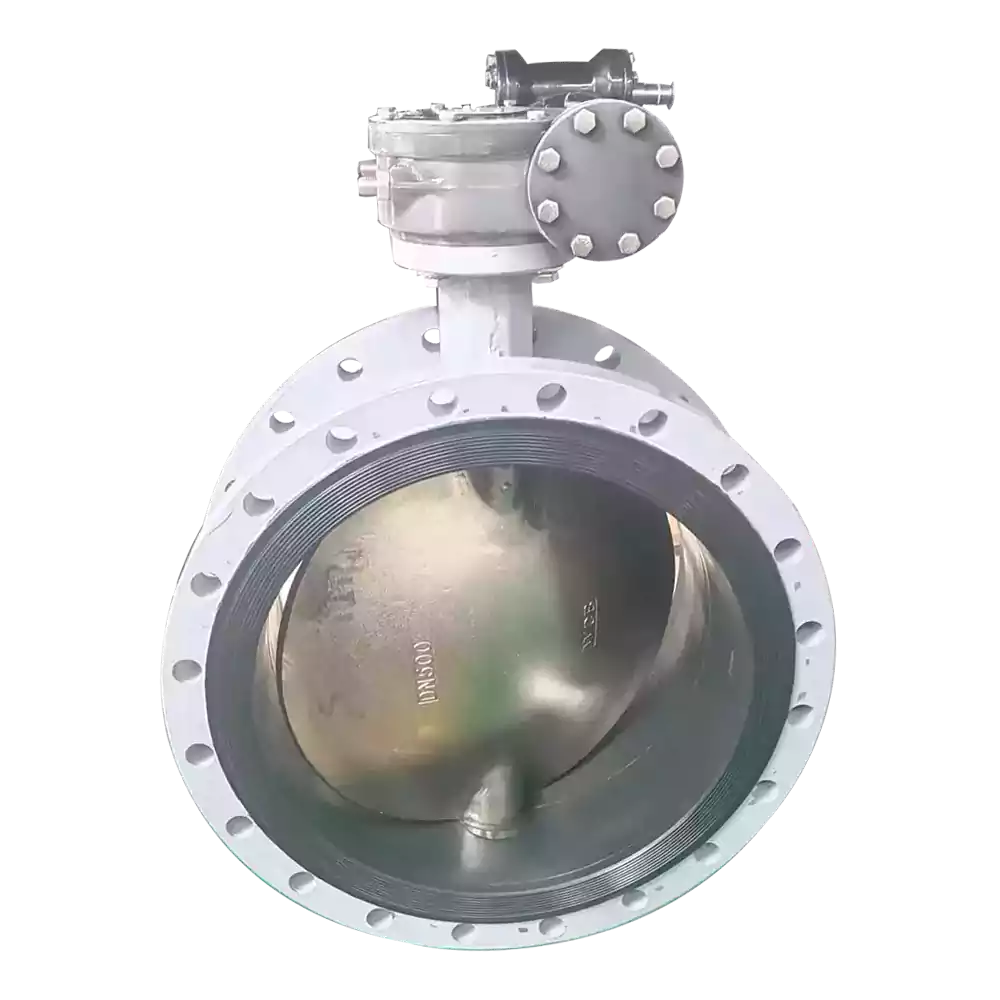

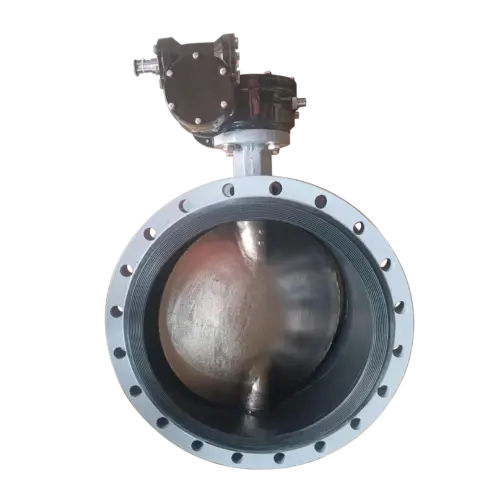

Vulcanized Seat WCB Double Flanged Butterfly Valve

Basic Info of Vulcanized Seat Butterfly Valve

| ITEM | Standard |

| Design | EN593 | API609 |

| Face to Face | EN558 | ISO5752 | API608 | BS5155-4 |

| Top Flange | ISO5211 |

| Flange Drilling | PN6 | PN10 | PN16 | ASME B16.5 CL150 | JIS 10K |

| Pressure Rating | PN6 | PN10 | PN16 | PN25 | CL150 | JIS 10K |

| Tightness Test | ISO5208 | API598 | EN12266-1 |

- Butterfly valves made of WCB material have good wear resistance. They can withstand relatively high wear and impact. During long-term use, they can reduce the possibility of valve wear and leakage and extend their service life.

- Vulcanized Seat WCB Double Flanged Butterfly Valve uses a vulcanized seat ring seal design to provide excellent sealing performance. It can effectively prevent fluid leakage and ensure the safety and stability of fluid pipelines.

- Compared with the soft seat butterfly valve, the vulcanized valve seat is fixed on the valve body, so there is no displacement. However, the vulcanized valve seat cannot be replaced, which is its only disadvantage.

- The flanged butterfly valve adopts a compact design, takes up little space, and is lightweight. This makes installation and maintenance easier and faster.

- WCB butterfly valve has excellent pressure resistance and rigidity, and can maintain stable performance under high temperature, high pressure and harsh environments, ensuring long-term reliable operation of the valve.

- The butterfly valve is designed to have a large flow capacity and low fluid resistance. This makes it suitable for scenarios requiring large flow control and improves system efficiency.

-

The Gearbox minimizes operational space while providing reliable torque transfer.

-

The two-piece stem design reduces wear and tear on moving parts.

Vulcanized Seat Flanged Butterfly Valve Parts

| Parts | Ductile Iron type | WCB type | Stainless Steel Type | Duplex Stainless Steel Type |

|---|---|---|---|---|

| Body | Cast Iron(GG25) Ductile Iron(GGG40/50) |

A216 A217 A105(forged) |

SS304/ CF8 SS316/CF8M SS304L/CF3 SS316L/CF3M |

2205 2507 1.4529 |

| Disc | Ductile Iron with Ni coated Ductile Iron with nylon coated Ductile Iron with PTFE/EPDM lined Stainless Steel Duplex Stainless Steel Bronze |

SS304/ CF8 SS316/CF8M SS304L/CF3 SS316L/CF3M 2205 2507 1.4529 |

2205 2507 1.4529 |

|

| Seat | NBR, EPDM, PTFE, Viton, Hypalon, Silicon, PFA | |||

| Stem | SS416, SS431, SS304, SS316, Duplex Stainless Steel, Monel | Duplex Stainless Steel, Monel | ||

| Actuator | Hand Lever, Worm Gear, Electric, Pneumatic | |||

Paraments of WCB Butterfly Valve

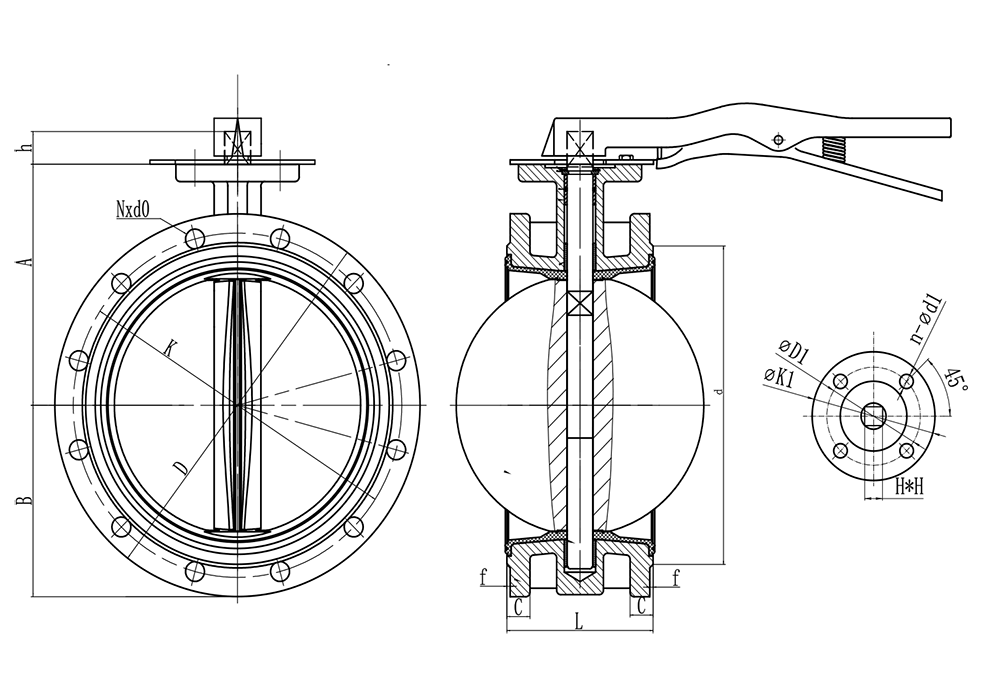

| DN | D | K | Nxd0 | d | C | L | f | A | B | K1 | D1 | n-d1 | HXH | h | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| PN10 | PN16 | PN10 | PN16 | PN10 | PN16 | PN10 | PN16 | PN10 | PN16 | ||||||||||

| DN50 | 165 | 125 | 4xø18 | 99 | 19 | 108 | 3 | 125 | 83 | 65 | 50 | 4-8 | 11X11 | 30 | |||||

| DN65 | 185 | 145 | 4xø18 | 118 | 19 | 112 | 3 | 142 | 93 | 65 | 50 | 4-8 | 11X11 | 30 | |||||

| DN80 | 200 | 160 | 8xø18 | 132 | 19 | 114 | 3 | 159 | 100 | 65 | 50 | 4-8 | 11X11 | 30 | |||||

| DN100 | 220 | 180 | 8xø18 | 156 | 19 | 127 | 3 | 165 | 130 | 90 | 70 | 4-10 | 11X11 | 30 | |||||

| DN125 | 250 | 210 | 8xø18 | 184 | 19 | 140 | 3 | 170 | 125 | 90 | 70 | 4-10 | 14X14 | 30 | |||||

| DN150 | 285 | 240 | 8xø22 | 211 | 20 | 140 | 3 | 185 | 143 | 90 | 70 | 4-10 | 14X14 | 30 | |||||

| DN200 | 340 | 295 | 8xø22 | 12xø22 | 270 | 20 | 152 | 3 | 228 | 150 | 125 | 102 | 4-12 | 17X17 | 35 | ||||

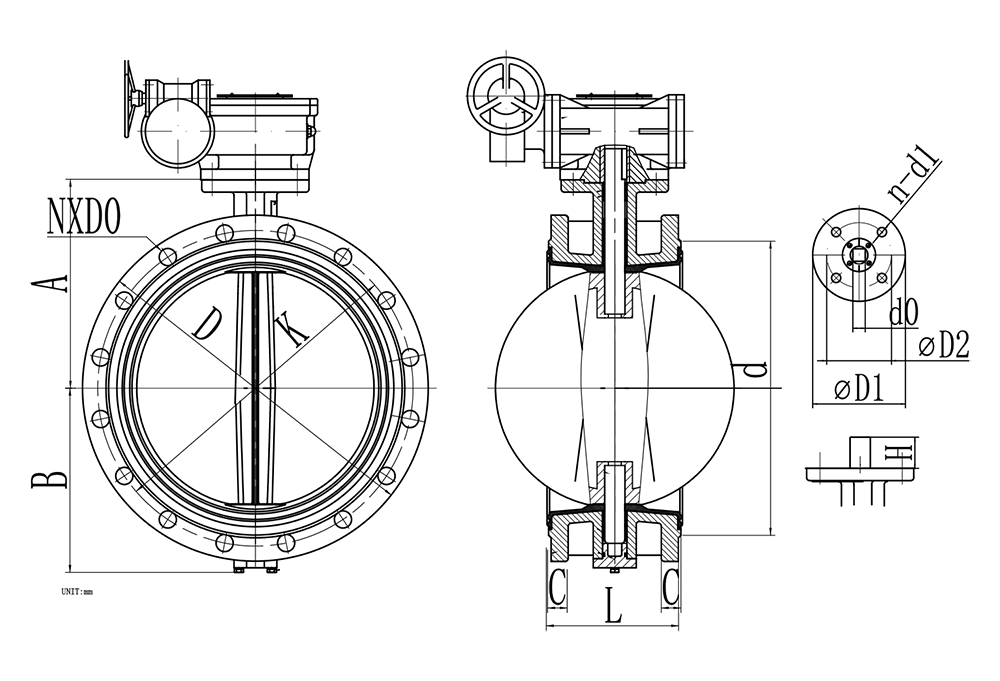

| DN | D | K | NxdO | d | C | L | f | A | B | D1 | D2 | n-d1 | d0 | H | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| PN10 | PN16 | PN10 | PN16 | PN10 | PN16 | PN10 | PN16 | PN10 | PN16 | ||||||||||

| DN250 | 395 | 405 | 350 | 355 | 12xø23 | 12xø28 | 319 | 22 | 165 | 3 | 279 | 200 | 125 | 102 | 4-12 | 22X22 | 35 | ||

| DN300 | 445 | 460 | 400 | 410 | 12xø23 | 12xø28 | 370 | 24 | 178 | 4 | 303 | 223 | 125 | 102 | 4-12 | 22X22 | 35 | ||

| DN350 | 505 | 520 | 460 | 470 | 16xø23 | 16xø28 | 429 | 24 | 28 | 190 | 4 | 330 | 245 | 150 | 125 | 4-14 | 22X22 | 35 | |

| DN400 | 565 | 580 | 515 | 525 | 16xø28 | 16xø31 | 480 | 28 | 36 | 216 | 4 | 370 | 272 | 175 | 140 | 4-18 | 27X27 | 50 | |

| DN500 | 670 | 715 | 620 | 650 | 20xø28 | 20xø34 | 582 | 609 | 26 | 32 | 229 | 4 | 430 | 339 | 210 | 165 | 4-22 | 36X36 | 50 |

| DN600 | 780 | 840 | 725 | 770 | 20xø31 | 20xø37 | 682 | 720 | 30 | 36 | 267 | 5 | 500 | 384 | 210 | 165 | 4-22 | 36X36 | 60 |

| DN700 | 895 | 910 | 840 | 24xø31 | 24xø37 | 794 | 32.5 | 39.5 | 292 | 5 | 560 | 480 | 300 | 254 | 8-18 | ø63.35 | 80 | ||

| DN800 | 1015 | 1025 | 950 | 24xø34 | 24xø40 | 901 | 35 | 41 | 318 | 5 | 620 | 530 | 300 | 254 | 8-18 | ø63.35 | 80 | ||

| DN900 | 1115 | 1125 | 1050 | 28xø34 | 28xø40 | 1001 | 36 | 44 | 330 | 5 | 685 | 605 | 300 | 254 | 8-18 | ø75 | 100 | ||

| DN1000 | 1230 | 1255 | 1160 | 1170 | 28xø37 | 28xø43 | 1112 | 40 | 50 | 410 | 5 | 735 | 670 | 300 | 254 | 8-18 | ø80 | 100 | |

| DN1200 | 1455 | 1485 | 1380 | 1390 | 32xø40 | 32xø49 | 1328 | 45 | 57 | 470 | 5 | 917 | 780 | 350 | 298 | 8-22 | ø90 | 100 | |

Manufacture Process of Butterfly Valve

Certificates of Zfa Valve

WRAS

CE

ISO 9001

EAC Russia