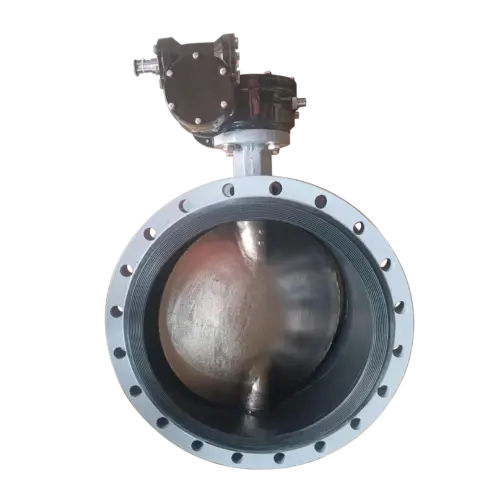

Wholesale Wafer PTFE Fully Lined Butterfly Valve

Features of PTFE Fully Lined Butterfly Valve

Compare to the EPDM Seat butterfly valve, the PTFE lined butterfly valve has some more advantages:

- Corrosion resistance: PTFE fully lined butterfly valve has excellent corrosion resistance to various corrosive liquids, including strong acids, strong alkalis, etc.

- Temperature Range: PTFE fully lined butterfly valve can withstand higher temperatures than EPDM,while It has a temperature range of approximately -250°C to +260°C (-418°F to +500°F)..

- Versatility: PTFE is also called “Plastic King” in China, so it is suitable for different types of media, whether it is corrosive or non-corrosive fluid.

- Low Friction: PTFE has a low coefficient of friction, reducing wear on valve components, as a result, it can increases service life and reduces maintenance.

- Universal Sealing Material: PTFE is a universal sealing material, as it is compatible with various flanges and gaskets.

- Unlike elastomeric seats, PTFE is less flexible or elastic. This can reduce its sealing performance in surge or vibration applications because the seat may not easily return to its original shape.

- PTFE fully lined butterfly valves are generally more expensive than other seat materials (such as EPDM or NBR), which can increase the overall cost of the valve.

- PTFE seats are generally available up to PN10. Above this pressure, we do not recommend the use of PTFE seats.

Basic Info of PTFE Fully Lined Butterfly Valve

Material

| Part Name | Material/Method |

| Body | Ductile Iron, Casting Iron, WCB, LCB/LCC, Stainless Steel, Duplex Stainless Steel, Aluminium Bronze |

| Disc | PTFE Fully Lined Ductile Iron, WCB, LCB/LCC, Stainless Steel, Duplex Stainless Steel, Aluminium Bronze |

| Seat | Rubber(EPDM/NBR/VITON), Nature Rubber, Silicon Rubber, PU, HNBR, Hypalon |

| Stem | 304, 316, 420(2Cr13), 431, 1.4462, 17-4PH, Monel |

| Actuator | Handlever, Worm Gear, Electric, Pneumatic |

Technical Parameters

| ITEM | Standard |

| Design | EN593 | API609 |

| Face to Face | EN558 | ISO5752 | API608 | BS5155-4 |

| Top Flange | ISO5211 |

| Flange Drilling | PN6 | PN10 | PN16 | ASME B16.5 CL150 | JIS 10K |

| Pressure Rating | PN6 | PN10 | PN16 | PN25 | CL150 | JIS 10K |

| Tightness Test | ISO5208 | API598 | EN12266-1 |

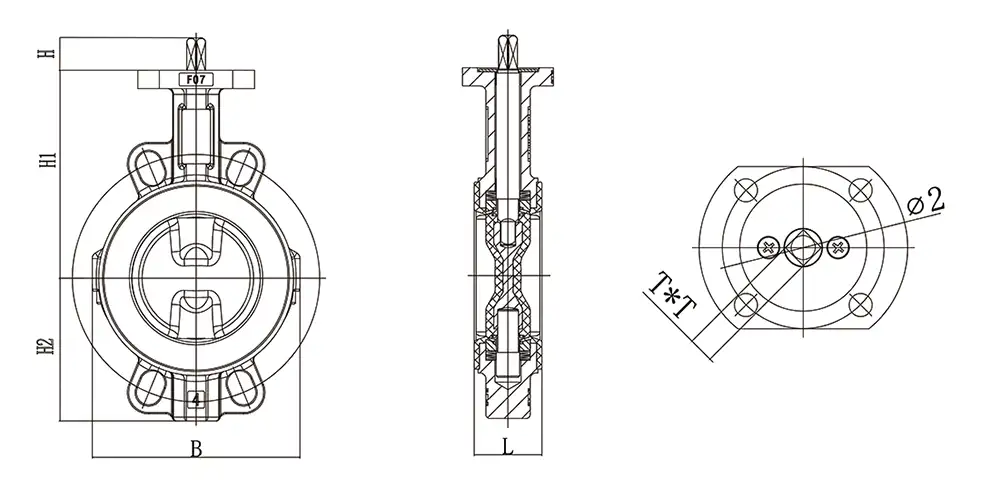

Paraments of PTFE Fully Lined Butterfly Valve

| SIZE | L | H1 | H2 | B | ø2 | T*T | H |

| DN50 | 43 | 134 | 68 | 100 | F05 | 9*9 | 25 |

| DN65 | 46 | 145 | 78 | 120 | F05 | 9*9 | 25 |

| DN80 | 46 | 150 | 80 | 140 | F05 | 9*9 | 25 |

| DN100 | 52 | 160 | 110 | 160 | F07 | 11*11 | 25 |

| DN125 | 56 | 178 | 130 | 190 | F07 | 14*14 | 25 |

| DN150 | 56 | 197 | 140 | 220 | F07 | 14*14 | 25 |

| DN200 | 60 | 239 | 175 | 277 | F10 | 17*17 | 30 |

| DN250 | 68 | 278 | 215 | 330 | F10 | 22*22 | 30 |

| DN300 | 78 | 315 | 250 | 380 | F12 | 22*22 | 30 |

| DN350 | 78 | 355 | 255 | 440 | F12 | 22*22 | 30 |

Manufacture Process of Butterfly Valve

Certificates

WRAS

CE

ISO 9001

EAC Russia