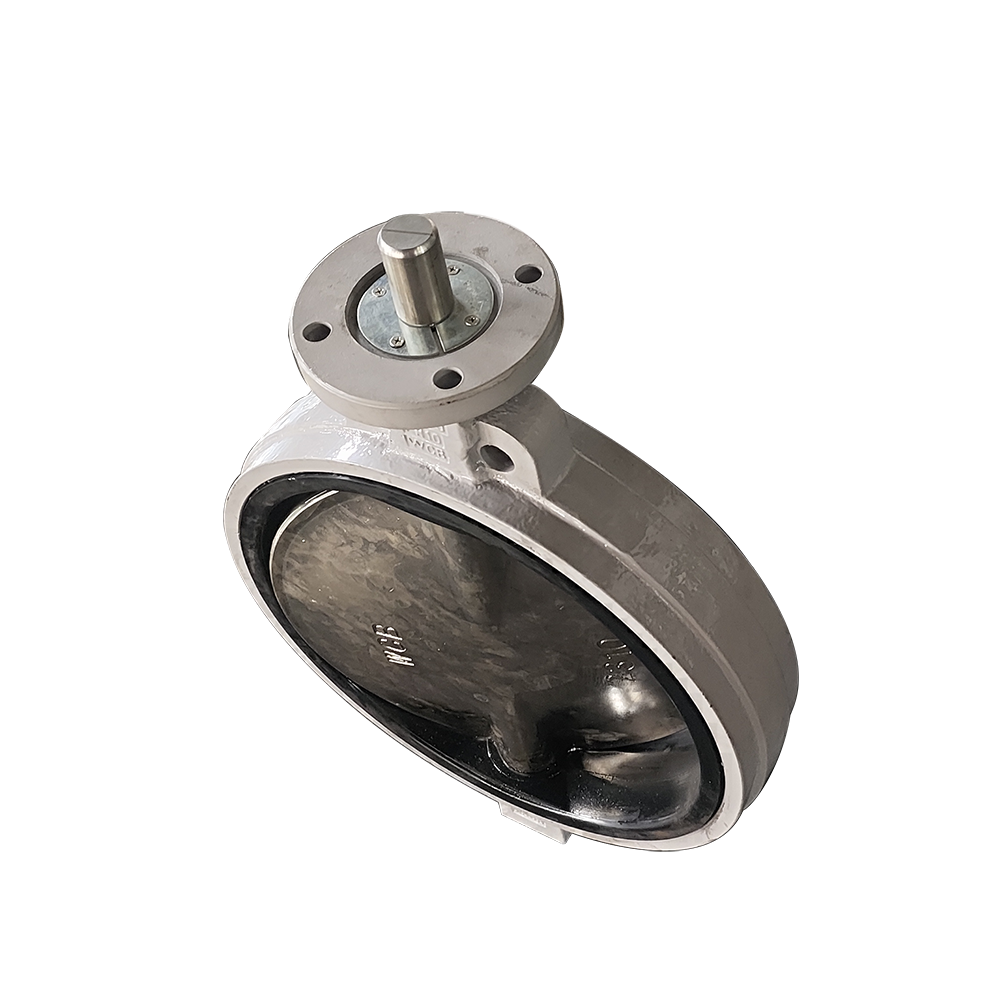

WCB Body & Disc Double Stem Wafer Butterfly Valve

Basic Info

- High heat resistance: WCB material butterfly valve has good high temperature resistance, can operate stably in high temperature environments, and is suitable for high temperature process fluid control.

- Good corrosion resistance: WCB butterfly valves can resist erosion from a variety of corrosive media, have a long service life, and reduce the frequency of maintenance and replacement.

- Strong toughness: WCB material butterfly valve has high strength and toughness, can withstand large pressure and impact, ensuring the stability and safety of the valve.

- Standard structure,Thick casting,Quick and light opening and closing, convenient maintenance.

- EPDM Seat of butterfly valve has Excellent chemical resistance, high temperature stability, Weather resistance and aging resistance, Water resistance and acid and alkali resistance, Moderate softness and hardness,

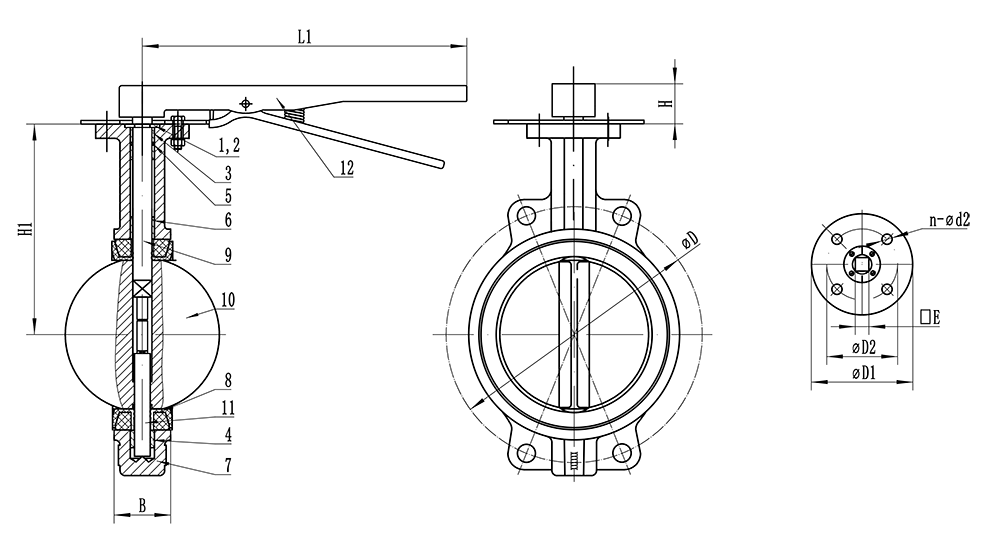

Paraments

| SIZE | H1 | B | øD | øDl | øD2 | n-ød2 | □E | H | Ll | ||

| PN10 PN16 | CL150A | ||||||||||

| DN40 | 121 | 33 | 110 | 98.4 | 65 | 50 | 4-ø7.5 | 9 | 25 | 170 | |

| DN50 | 131 | 42 | 125 | 120.7 | 65 | 50 | 4-ø7.5 | 9 | 25 | 170 | |

| DN65 | 142 | 44.7 | 145 | 139.7 | 65 | 50 | 4-ø7.5 | 9 | 25 | 170 | |

| DN80 | 150 | 45 | 160 | 152.4 | 65 | 50 | 4-ø7.5 | 9 | 25 | 170 | |

| DN100 | 170 | 51.2 | 180 | 190.5 | 90 | 70 | 4-ø10 | ll | 25 | 215 | |

| DN125 | 184 | 54.4 | 210 | 215.9 | 90 | 70 | 4-ø10 | 14 | 25 | 215 | |

| DN150 | 200 | 55 | 240 | 241.3 | 90 | 70 | 4-ø10 | 14 | 25 | 215 | |

| DN200 | 240 | 58.8 | 295 | 298.5 | 90 | 70 | 4-ø10 | 17 | 35 | 265 | |

| DN250 | 270 | 65.7 | 350 | 355 | 362 | 125 | 102 | 4-ø12 | 22 | 35 | 350 |

| DN300 | 310 | 76 | 400 | 410 | 431.8 | 125 | 102 | 4-ø12 | 22 | 35 | 350 |

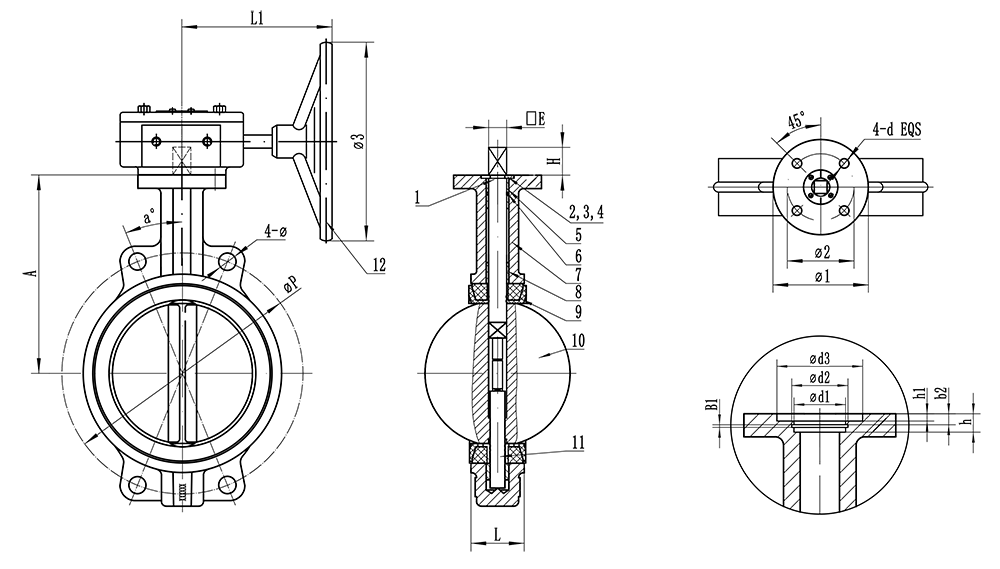

| SIZE | A | øP | 4-ø | a° | L | ø1 | ø2 | 4-d | □E | H | L1 | ∅3 | ||||||

| PN10 | PN16 | CL150 | PN10 | PN16 | CL150 | PN10 | PN16 | CL150 | ||||||||||

| DN350 | 368 | ∅460 | ø470 | ∅476.2 | 4-∅23 | 4-∅28 | 4-ø28.4 | 11.25° | 11.25° | 22.5° | 76.5 | ∅140 | ø102 | 4-ø12 | 22 | 45 | 174 | 460 |

| DN400 | 400 | ø515 | ø525 | ø539.7 | 4-ø28 | 4-ø31 | 4-ø28.4 | 11.25° | 11.25° | 11.25° | 85.7 | ø175 | ∅140 | 4-ø18 | 27 | 50 | 195 | 460 |

| DN450 | 422 | ø565 | ø585 | ø577.8 | 4-ø28 | 4-ø31 | 4-∅31.8 | 9° | 9° | 11.25° | 104.6 | ø175 | ø140 | 4-ø18 | 27 | 50 | 195 | 550 |

| DN500 | 480 | ø620 | ∅650 | ø635 | 4-∅28 | 4-ø34 | 4-ø31.8 | 9° | 9° | 9° | 130.28 | ø175 | ø140 | 4-ø18 | 32 | 55 | 195 | 600 |

| DN600 | 562 | ø725 | ø770 | ø749.3 | 4-∅31 | 4-ø37 | 4-∅35.1 | 9° | 9° | 9° | 151.36 | ∅210 | ø165 | 4-∅23 | 36 | 68 | 240 | 700 |

Manufacture Process

Certificates

WRAS

CE

ISO 9001

EAC Russia