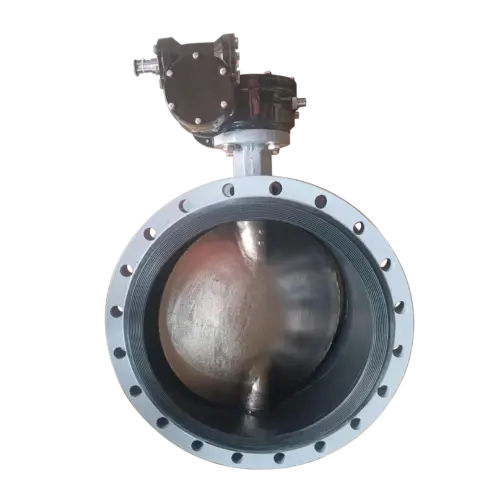

Worm Gear Hard Back Seat CF8M Disc Pin Wafer Butterfly Valve

Basic Info of Pin Wafer Butterfly Valve

- Worm Gear: This pin wafer butterfly valve adopts worm gear drive mode, which is suitable for application scenarios with a diameter of ≥300 or requiring more precise control. The torque is amplified by the worm gear mechanism, making the operation easier.

- The Hard Back Seat is made of metal or other wear-resistant materials, which fits better with the valve body and is not easy to misalign, but it is not easy to replace if it is broken.

- The CF8M Disc is austenitic stainless steel, equivalent to ANSI 316 stainless steel. It has excellent corrosion resistance, so the pin wafer butterfly valve is suitable for corrosive media such as seawater and chemicals.

- Pin refers to the connection between the valve plate and the valve stem, which is fixed by a pin shaft. The pin allows the valve plate to rotate reliably to ensure stable opening and closing actions.

Technical Parameters of Pin Wafer Butterfly Valve

Material

| Part Name | Material/Method |

| Body | Ductile Iron, Casting Iron, WCB, LCB/LCC, Stainless Steel, Duplex Stainless Steel, Aluminium Bronze |

| Disc | Ductile Iron(Coated/Lined), WCB, LCB/LCC, Stainless Steel, Duplex Stainless Steel, Aluminium Bronze |

| Seat | Rubber(EPDM/NBR/VITON), Nature Rubber, Silicon Rubber, PU, HNBR, Hypalon |

| Stem | 304, 316, 420(2Cr13), 431, 1.4462, 17-4PH, Monel |

| Actuator | Handlever, Worm Gear, Electric, Pneumatic |

Technical Parameters

| ITEM | Standard |

| Design | EN593 | API609 |

| Face to Face | EN558 | ISO5752 | API608 | BS5155-4 |

| Top Flange | ISO5211 |

| Flange Drilling | PN6 | PN10 | PN16 | ASME B16.5 CL150 | JIS 10K |

| Pressure Rating | PN6 | PN10 | PN16 | PN25 | CL150 | JIS 10K |

| Tightness Test | ISO5208 | API598 | EN12266-1 |

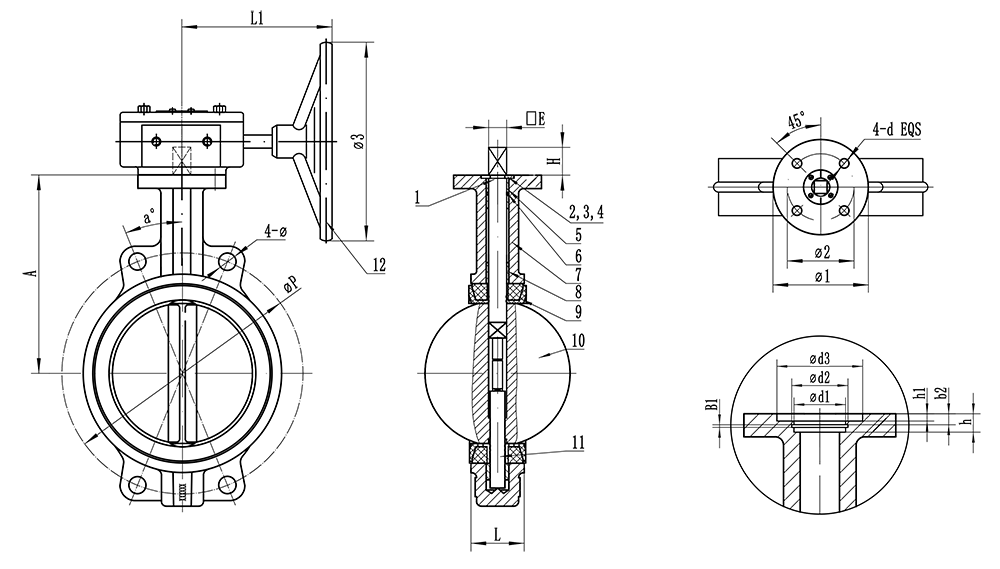

Drawing and Dimension of Pin Wafer Butterfly Valve

| SIZE | A | øP | 4-ø | a° | L | ø1 | ø2 | 4-d | □E | H | L1 | ∅3 | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| PN10 | PN16 | CL150 | PN10 | PN16 | CL150 | PN10 | PN16 | CL150 | ||||||||||

| DN350 | 368 | ∅460 | ø470 | ∅476.2 | 4-∅23 | 4-∅28 | 4-ø28.4 | 11.25° | 11.25° | 22.5° | 76.5 | ∅140 | ø102 | 4-ø12 | 22 | 45 | 174 | 460 |

| DN400 | 400 | ø515 | ø525 | ø539.7 | 4-ø28 | 4-ø31 | 4-ø28.4 | 11.25° | 11.25° | 11.25° | 85.7 | ø175 | ∅140 | 4-ø18 | 27 | 50 | 195 | 460 |

| DN450 | 422 | ø565 | ø585 | ø577.8 | 4-ø28 | 4-ø31 | 4-∅31.8 | 9° | 9° | 11.25° | 104.6 | ø175 | ø140 | 4-ø18 | 27 | 50 | 195 | 550 |

| DN500 | 480 | ø620 | ∅650 | ø635 | 4-∅28 | 4-ø34 | 4-ø31.8 | 9° | 9° | 9° | 130.28 | ø175 | ø140 | 4-ø18 | 32 | 55 | 195 | 600 |

| DN600 | 562 | ø725 | ø770 | ø749.3 | 4-∅31 | 4-ø37 | 4-∅35.1 | 9° | 9° | 9° | 151.36 | ∅210 | ø165 | 4-∅23 | 36 | 68 | 240 | 700 |

Manufacture Process of Pin Wafer Butterfly Valve

Certificates of ZFA Valve

WRAS

CE

ISO 9001

EAC Russia