In many industries, butterfly valves are the staple for efficient flow control. Their simple designs facilitate precise fluid movement through pipelines, making them efficient and helping to save time. This makes them a common option for many industries in their applications. Butterfly valves come in different types. The most common are double and triple-offset butterfly valves. These two valves share many similarities, but their differences set them apart. What are the differences between the double offset vs triple offset butterfly valve? We will provide you with the answers you need through this post.

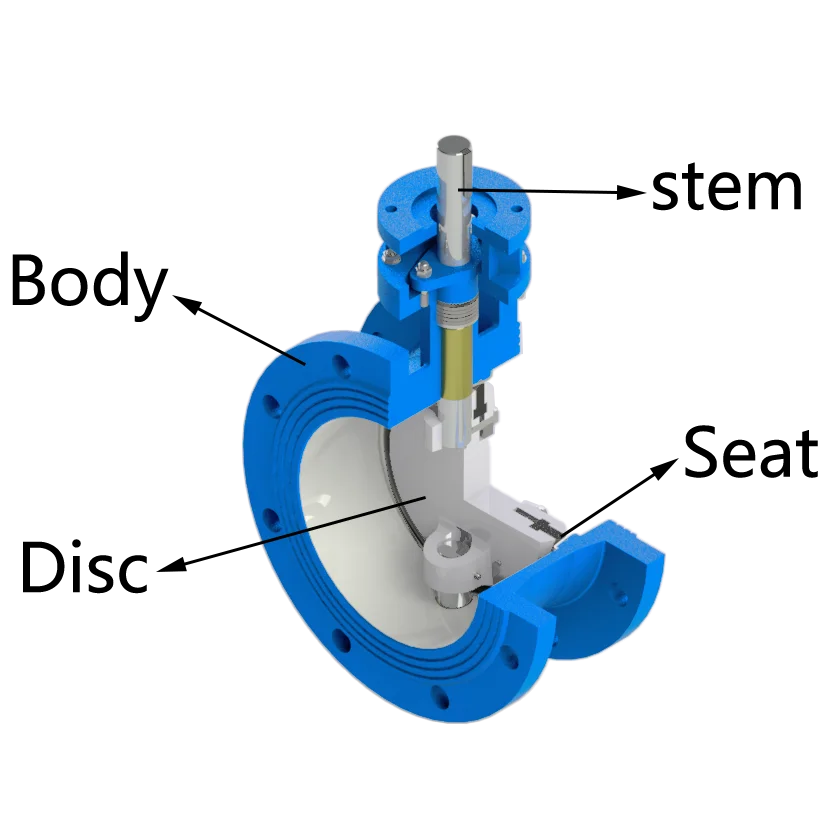

The standard design of a butterfly valve has a round disc that moves around a central shaft. This disc aligns perfectly with the centre of the pipe. However, in offset valves, there are intentional errors in place to improve performance.

In a double offset butterfly valve, there are two offsets. The first one places the rod or shaft angled to the back slightly, away from the sealing area. While the second offset pushes the axis of the rod away from the centre of the pipeline.

Alterations like these encourage a cam-like action that reduces friction between the disc and seat. To understand this, imagine the rod bent in the valve like a slanted ramp. When you turn the handle, the disc will slide up this ramp and push the rod against the seal when closed.

The interesting part is the ramp limits rubbing between the disc and seal until the valve is shut. The main advantage of this is the reduction of wear and tear in the valve. As a result, the valve will last longer and maintain its performance. Hence, why double-offset butterfly valves are called “high-performance butterfly valves.”

A double-offset butterfly valve can handle various temperatures and pressures, making it suitable for use in many industries.

- Oil and gas

- Water treatment

- Power generation

- Chemical processing plants

However, double-offset butterfly valves have their cons. For one, their complexity makes them pricier than standard butterfly valves, making them unsuitable for industries with limited operational budgets.

What is a Triple Offset Butterfly Valve?

If you thought double offsets were game-changers in the valve world, sit tight. Triple offsets take things to another level.

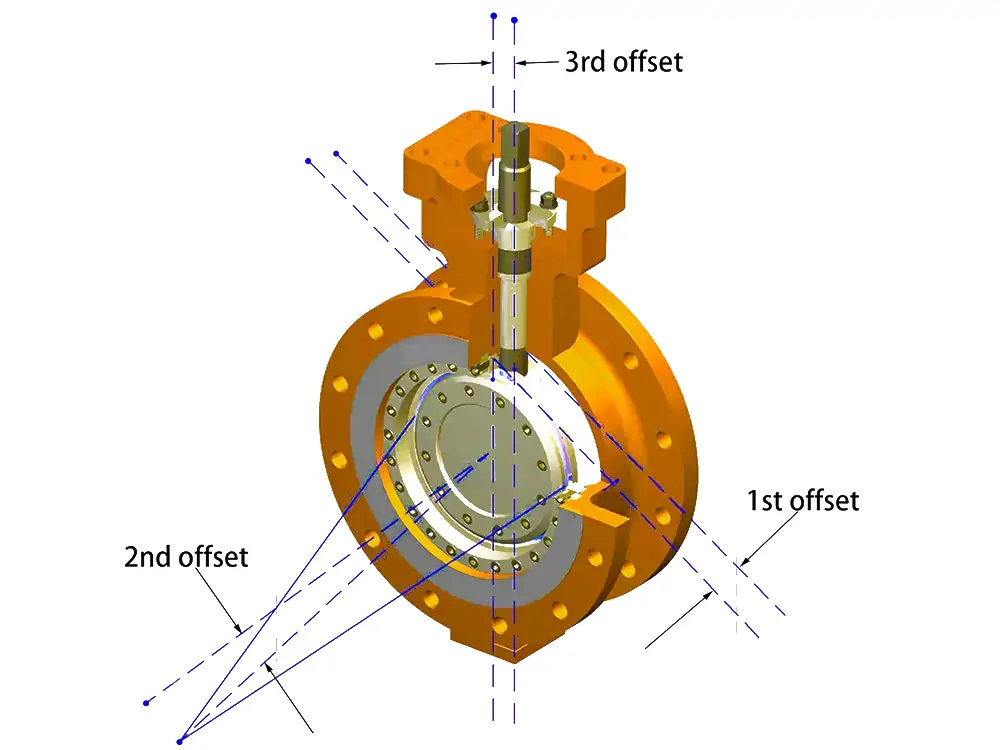

Unlike its counterpart, a triple-offset butterfly valve has three offsets. The first two are what we see in a double-offset valve, while the third offset is the most critical.

In these valves, the seating surface takes a conical shape. This modification allows the disc to create a metal-to-metal seal that prevents wear. These clever features make triple-offset valves great tools for reliable fluid control.

Due to the close contact between the disc and the seat, a triple offset butterfly valve has a very tight seal. This makes it perfect for intense industrial conditions that other valves cannot handle, such as high temperatures, pressures, and harsh chemicals.

The cons of these devices relate to their cost and their specific uses. This is due to their complex designs and their appliance to few applications. Nevertheless, the plus sides of a triple-offset butterfly valve make it a valuable tool. These include;

- Zero leakage during use

- High durability

- Reduced wear and tear, which extends the valve’s lifespan

- Resistance to harsh industrial environments

- Low maintenance

A triple offset butterfly valve is ideal for industries that need high quality, efficiency, and sealing integrity. Oil and gas, paper, and power generation are common industries that use them.

Double Offset VS Triple Offset Butterfly Valve

Knowing what separates a double-offset from a triple-offset butterfly valve is crucial. These two types of butterfly valves have their pros and cons. They each have qualities that set them apart and make them perfect for specific uses.

This section will highlight the key features that set both valves apart. This comparison will simplify your selection process, so read on for more.

1. Cost

A double-offset valve is less expensive than a triple-offset valve. This applies to both the initial cost and maintenance expenses over time. Double-offset valves have less complex designs and thus use cheaper manufacturing materials, making them a cost-effective solution for many applications.

However, although expensive, triple-offset valves provide users with long-term financial benefits. A triple-offset butterfly valve is designed to be durable. Due to its advanced structures, it causes less wear and increases the valve’s life expectancy. This means it is cheaper to maintain, making it a wise investment in the long run.

2. Sealing performance

Triple offsets create a bubble-tight seal that prevents leakage in the pipeline. This high-sealing performance is due to their unique three-flanged design. Their unique design ensures that the valve closes more securely and precisely. Hence, triple offset butterfly valves are the “it choice” for situations where preventing leaks is vital. Double offset valves also provide good sealing, but not to the same extent as triple offsets.

3. Performance under extreme conditions

Triple-offset valves are the best options for intense industrial conditions like high temperatures and pressures. Their design allows them to operate in tough situations without a drop in efficiency. They can handle the most demanding situations without compromising quality and lifespan. Double-offset valves function in more delicate scenarios, but this makes them more versatile in their applications, unlike triple-offset valves. This takes us to our final comparison.

4. Versatility

Double-offset valves are versatile and can function in many industrial settings. Their design allows them to handle moderate pressures and temperatures. This makes them suitable for simple processes like power generation and water treatment. On the other hand, triple-offset valves function in demanding environments. These valves excel where maximum sealing and performance are important. A triple-offset design creates a tight, leak-proof seal that prevents fluid leakage. Double-offset valves are more adaptable, making them ideal for many industrial uses.

Therefore, your choice depends on your specific needs. Double offsets will suffice if you need a budget-friendly valve that prevents leakage and wear. But, if you require a powerful valve to keep up with intensity, choose triple offsets.