What is Pneumatic Butterfly Valve?

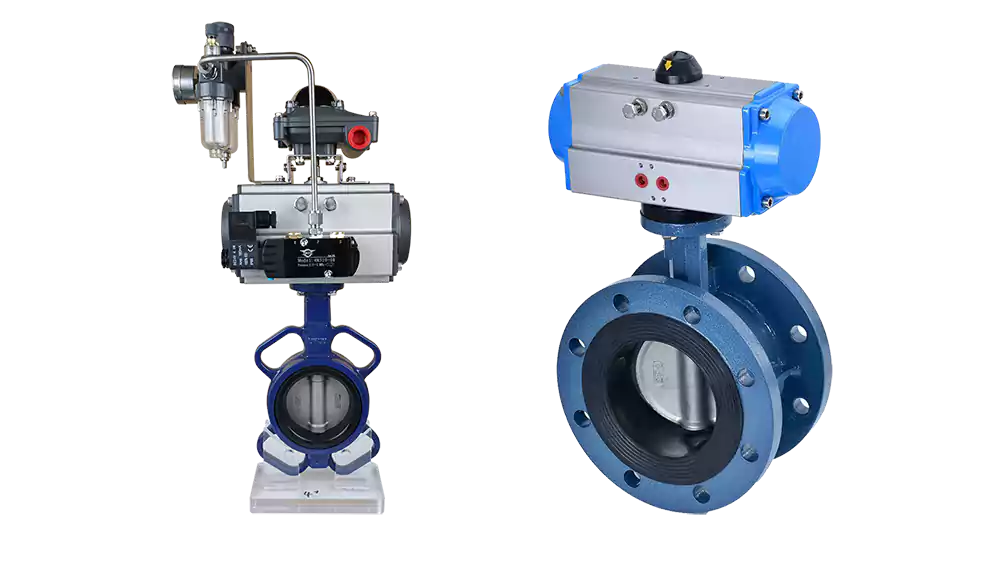

Pneumatic butterfly valve consists of two parts: pneumatic actuator and butterfly valve.

A butterfly valve is a valve used to control the medium(liquids or gases), The main characteristics of butterfly valves are simple structure, small size, light weight, and rapid opening and closing movements. They are commonly used in piping systems for controlling fluids in different industrial and commercial applications.

Pneumatic actuators are a commonly used industrial automation equipment used to control and operate mechanical devices such as valves. It is an actuator device that uses air source to pressure drive opening and closing or regulating valves. Compared with electric actuators, pneumatic actuators execute very quickly, up to 0.05 seconds per time! According to the supply method of compressed air or gas, pneumatic actuators can be divided into two types: single-acting and double-acting. There are some important differences between them, and this article will discuss the differences between single-acting and double-acting actuators in detail.

single action pneumatic actuator

double action pneumatic actuator

1. Working principle of single-acting actuator and double-acting actuator.

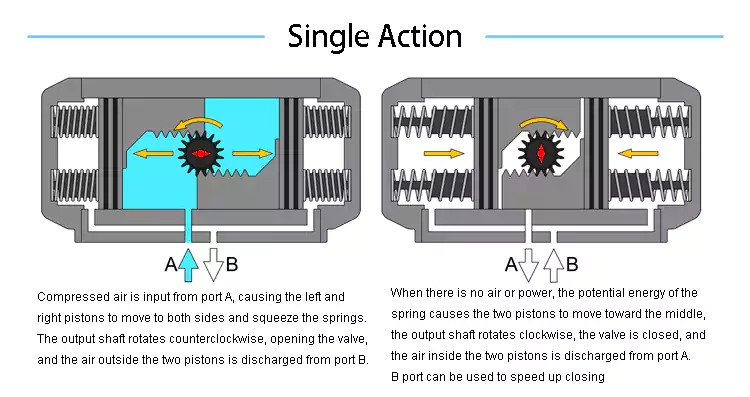

The single-acting actuator applies pressure to its interior through the air, thereby generating a unidirectional force to rotate the valve plate to open the valve. When the air applies pressure, the actuator moves in one direction. When the air releases pressure, the actuator returns to its original position by spring or gravity.

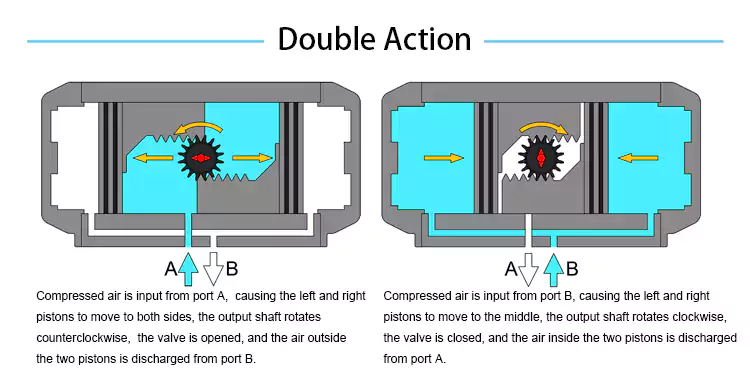

The double-acting actuator is an air-opening and air-closing type, which requires the air whether it is opening or closing. The valve is open when the aire is used. and the valve woule be closed when the air is used on the other side. In other words, the cylinder and valve are reset by the air. When the air source is lost, it can only maintain the current state. The actuator can continue to work after the air source is reconnected.

2. Classification

Single acting pneumatic actuator: normally open type and normally closed type. .

The normally open type: close by air, and open by air cut off: cylinder is opened, while it will automatically reset to the initial closed state when the air source is lost.

The normally closed type: open by air, and close by air cut off: cylinder is closed, while it will automatically reset to the initial open state when the air source is lost.

The switching actions of the double-acting cylinder are all driven by the air source; cylinder is open when air is on; cylinder is remain in place when the air is cut off, so there is no secondary classification.

3. The amount of air source required is different.

Single-acting cylinders are more air-efficient than double-acting cylinders, but the torque or thrust of single-acting cylinders is smaller than that of double-acting cylinders. Double-acting cylinders require an air source to provide power to open or close valves, while single-acting cylinders only require an air source to open or close.

4. The usage conditions are different.

The choice of single-acting cylinder and double-acting pneumatic is based on on-site working conditions. Single-acting pneumatic actuators are often used in dangerous working conditions. They can quickly close the valve when the air source is lost then a sudden failure occurs. Or open. For example, in some pipelines, if the air source fails, the valve must be open or closed. In this case, you need to choose a single-acting cylinder.

Double-acting pneumatic actuators are generally used in working conditions where leakage requirements are not high.

The single-acting cylinder has a spring inside. For example, when the valve is not ventilated, the valve is closed, which is often called an air-opening type. At this time, the ventilation source of the cylinder will compress the spring inside. When the air source is interrupted, the spring will The reset drives the valve stem to close the valve. If you need the valve to open when it loses the air source, you only need to set the initial position of the valve to open during assembly.

5. Different costs

In terms of price, single-acting pneumatic actuators have one more set of springs than double-acting actuators, so the price will be higher.

ZFA Pneumatic Butterfly Valves

ZFA Valve factory is a professional manufacturer of butterfly valve, we have a pneumatic actuator manufacturer with many years of cooperation. Of course, your designated pneumatic actuator manufacturer is acceptable.

Pneumatic wafer butterfly valve, Pneumatic flange butterfly valve, Pneumatic lug butterfly valve is available in Zfa valve factory. Both single action pneumatic butterfly valve and double action pneumatic butterfly valve are optional.