This article discusses the concept of a triple offset butterfly valve, its working principle, their advantages and disadvantages associated with its use. It also provides information on the differences between concentric and triple eccentric butterfly valves, as well as drawings of triple eccentric butterfly valves.

-

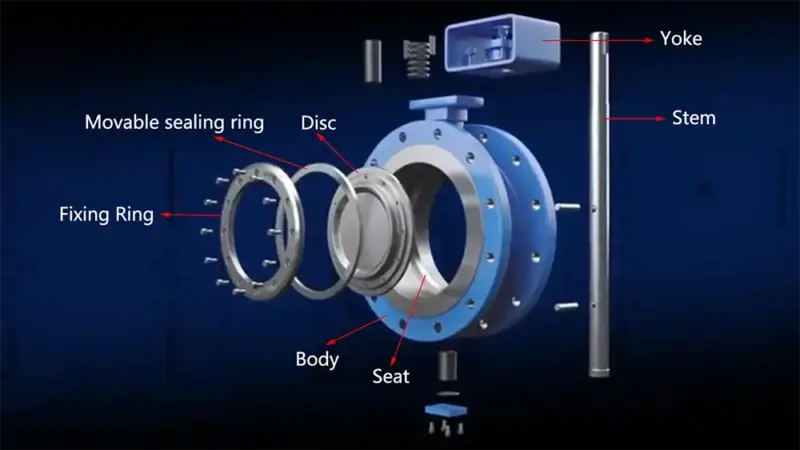

What is a Triple Offset Butterfly Valve

The triple eccentric butterfly valve is a hard-sealed butterfly valve with three eccentric structures. It has three eccentric designs: eccentric shaft, eccentric cone and eccentric seat. Therefore, the triple eccentric butterfly valve can withstand higher temperatures and greater pressures and achieve better sealing performance.

-

How does the triple offset butterfly valve work?

- Closed state: When the valve is closed, the valve stem drives the valve plate to rotate, so that the three eccentricities of the valve plate are in contact with the sealing surface of the valve seat without friction, and the valve shaft is not in contact with the sealing surface. These designs reduce wear, thereby extending the service life of the butterfly valve.

- Open state: When the valve needs to be opened, the valve disc begins to rotate along the valve axis and gradually separates from the valve seat sealing surface, thus reducing the friction between the valve plate and the valve seat. The valve torque is reduced and wear is reduced.

-

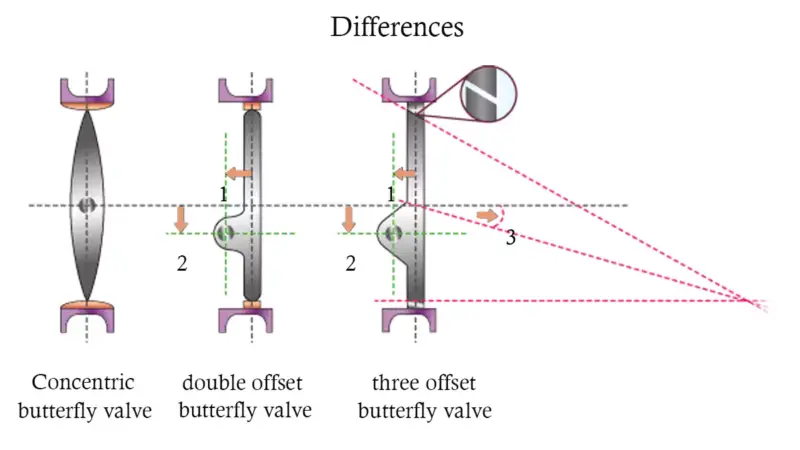

The difference between concentric butterfly valve and triple eccentric butterfly valve

-

Concentric Butterfly Valve

Concentric butterfly valve is a simple and common type of butterfly valve. Its design is relatively simple and simple: the valve disc of the concentric butterfly valve is designed to be circular, rotating around the center of the valve shaft, and forming a concentric structure with the valve seat.

- Sealing principle: The valve plate is squeezed in an elastic valve seat (rubber, PTFE, etc.) to achieve sealing and prevent fluid from passing through the pipeline.

- Easy to operate: The actuator (handle, electric or pneumatic) controls the rotation of the valve stem, thereby driving the valve plate away from the valve seat to allow the medium to pass.

- Applicable temperature and pressure: Concentric butterfly valves are suitable for fluid control applications with temperatures ranging from -10 to 120 degrees and pressures PN6-PN25, such as water supply, drainage and general industrial fluids.

-

Triple eccentric Butterfly Valve

The triple eccentric butterfly valve adopts a different design principle from the concentric butterfly valve to cope with more severe working conditions.

- Sealing principle: Unlike the concentric butterfly valve, the valve disc of the triple eccentric butterfly valve does not form a concentric structure with the valve seat when closed, ensuring more reliable sealing performance.

- High temperature and high pressure applications: Due to its metal to metal seal, triple offset butterfly valve is usually used in demanding high temperature and high pressure working conditions –temperature -196 to 650℃, pressure PN10-PN160 (ANSI CL 150~CL900), such as chemical industry, petroleum and the natural gas industry.

-

Advantages of triple eccentric valve

- High temperature and high pressure resistance: Compared with concentric butterfly valves, single-eccentric butterfly valves and double-eccentric butterfly valves, triple-eccentric butterfly valves can withstand high temperatures and high pressures.

- Reduced Friction: Triple-eccentric butterfly valves reduce friction during valve operation, resulting in smoother performance and enhanced durability.

- Wide range of applications: Triple eccentric butterfly valves can withstand harsh environments and are suitable for a wide range of applications in oil and gas, petrochemical, power generation and water treatment industries.

-

Disadvantages of triple eccentric valve

- High cost: Compared with traditional butterfly valves, the structure of triple eccentric butterfly valves is relatively complex, so it will resulty higher manufacturing costs.

- Complex maintenance: The complex design of the triple offset butterfly valve leads to increased maintenance costs.

6.triple offset butterfly valve manufacturer

Zfa Valve is a professional tri eccentric butterfly valve facoty with almost 20 years of producing and exporting experience, so we are always here to help any customer who wants to know the details.