1. Valves and Water Flow Control Valves are devices that regulate, start, or stop the flow of liquids, like water, in pipelines. They work by opening, closing, or partially blocking the flow path. What is the Best Valve to Control Water Flow? The “best” valve depends on several factors: Application: Is the valve for home,…

Butterfly valves are crucial in many industries. They are used in water treatment, oil and gas, chemical processing, plumbing systems, and more. Their primary function is to regulate the flow of fluids through pipelines. Because they work in a challenging environment, they should be properly taken care of. If you do not maintain them, they…

Dear Valued Partner, We are delighted to invite you to visit us at the ECWATECH 2025 exhibition, the premier water industry event in Russia and Eastern Europe, held at the Crocus Expo International Exhibition Centre in Krasnogorsk, Moscow. • Event: ECWATECH 2025 • Dates: September 9–11, 2025 • Booth: 8C8.6 • Location: Crocus Expo International…

Founded in 2006, ZFA Valves is a leading OEM/ODM manufacturer of industrial valves, specializing in butterfly valves, gate valves, and check valves. ZFA valves’ OEM/ODM services are available to customers in industries such as water treatment, HVAC, chemicals, and food and beverage. ZFA Valves is certified by ISO, CE, and WRAS, ensuring strict quality control…

The valves are used in pipelines to stop or allow the flow of the fluid or gases. Right? The valve seat is a primary component of the valve. And its durability significantly enhances the overall performance of the valve. Two key materials used in the manufacture of valves are EPDM and PTFE. These two materials…

The price of butterfly valves varies due to a variety of factors. Understanding the key factors affecting butterfly valve prices not only helps with purchasing decisions, but also optimizes project budgets.This article will delve into the 8 main factors that affect butterfly valve prices, combining industry trends and actual cases to provide practical insights. 1….

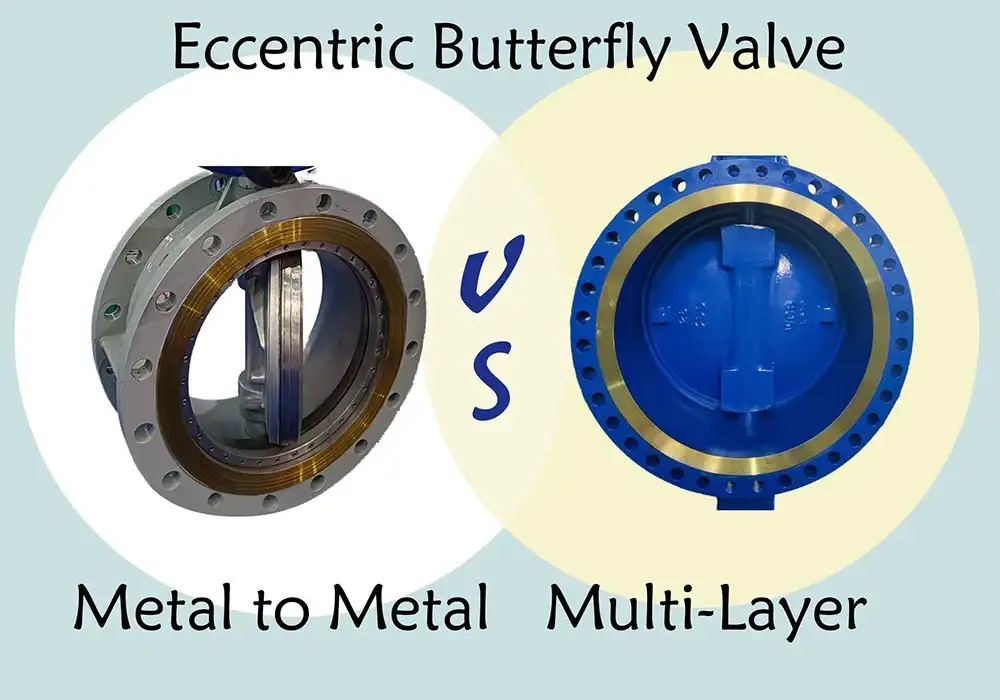

When customers purchase triple eccentric butterfly valves, they typically choose between two types: metal-to-metal seat butterfly valves vs multi-layer sealing butterfly valves. Let’s explore their similarities and differences to guide you in selecting the right valve. 1. Features of Multi-Layer Triple Eccentric Butterfly Valves Multi-layer butterfly valves have a complex sealing structure. The sealing ring consists…

Choosing the right industrial valves can feel like a big decision, but it doesn’t have to be overwhelming. For managing a sprawling chemical plant or a compact HVAC setup, picking the perfect valve involves navigating a maze of factors, from material compatibility to pressure ratings and industry standards. It is not just about finding a…

Single Flange Butterfly Valve Overview Many butterfly valve types exist. One design stands out, though less known. The single flange butterfly valve plays a key role. This article covers its design, function, applications, advantages, and limitations in detail. 1. Definition of Single Flange Butterfly Valve. What is a single flange butterfly valve? It differs from…