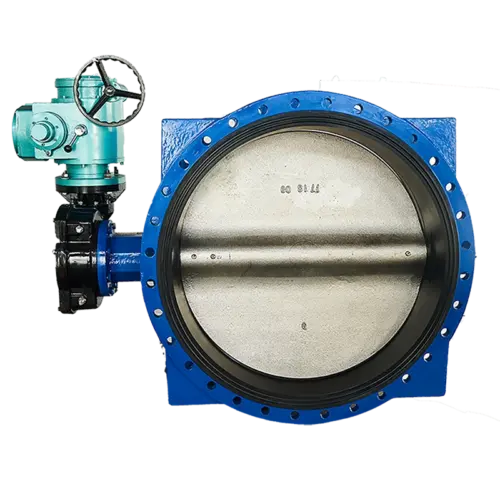

DN400 PN10 Gear OP EPDM Seat Two Shaft Lug Butterfly Valve

Basic Info of Lug EPDM Seat Two Shaft Lug Butterfly Valve

- Two Shaft Lug Butterfly Valve can be used for dead end service.

- Dovetail replaceable soft back seat lug butterfly valve refers to the fully lug wafer butterfly valve with the EPDM soft seat which can be replaced, it can reduce the cost when the seat is brocken.

- Excellent sealing and chemical resistance: EPDM valve seat has high elasticity and resilience, so it can effectively seal the valve and prevent leakage and leakage. besides,It has excellent chemical stability, can resist corrosion and erosion from a variety of chemicals, and is suitable for various media.

- Temperature adaptability: EPDM valve seats can work normally in a wide temperature range, with good heat resistance and cold resistance from minus 20 to 80 degrees Celsius.

- Lug design: Lug butterfly valve has a lug design, which can reduce the erosion of the valve seat and sealing ring by the medium, and improve the service life and reliability.

- Centerline design: This lug butterfly valve adopts a centerline design, which makes the valve action more stable and accurate, reduces the opening and closing torque, and improves operating performance and ease of use.

- The precision-machined Stainless Steel 316 disc features a two-piece stem construction that enhances the valve’s flow capabilities and reduces turbulence.

- A two shaft lug butterfly valve features two stems, one for the disc operation and another for additional stability. This ensure enhanced durability and performance of the lug butterfly valve.

Material Options of EPDM Seat Two Shaft Lug Butterfly Valve

| Parts | Ductile Iron type | WCB type | Stainless Steel Type | Duplex Stainless Steel Type |

|---|---|---|---|---|

| Body | Cast Iron(GG25) Ductile Iron(GGG40/50) |

A216 A217 A105(forged) |

SS304/ CF8 SS316/CF8M SS304L/CF3 SS316L/CF3M |

2205 2507 1.4529 |

| Disc | Ductile Iron with Ni coated Ductile Iron with nylon coated Ductile Iron with PTFE/EPDM lined Stainless Steel Duplex Stainless Steel Bronze |

SS304/ CF8 SS316/CF8M SS304L/CF3 SS316L/CF3M 2205 2507 1.4529 |

2205 2507 1.4529 |

|

| Seat | NBR, EPDM, PTFE, Viton, Hypalon, Silicon, PFA | |||

| Stem | SS416, SS431, SS304, SS316, Duplex Stainless Steel, Monel | Duplex Stainless Steel, Monel | ||

| Actuator | Hand Lever, Worm Gear, Electric, Pneumatic | |||

Lug style Butterfly Valve Standards

| ITEM | Standard |

| Design | EN593 | API609 |

| Face to Face | EN558 | ISO5752 | API608 | BS5155-4 |

| Top Flange | ISO5211 |

| Flange Drilling | PN6 | PN10 | PN16 | ASME B16.5 CL150 | JIS 10K |

| Pressure Rating | PN6 | PN10 | PN16 | PN25 | CL150 | JIS 10K |

| Tightness Test | ISO5208 | API598 | EN12266-1 |

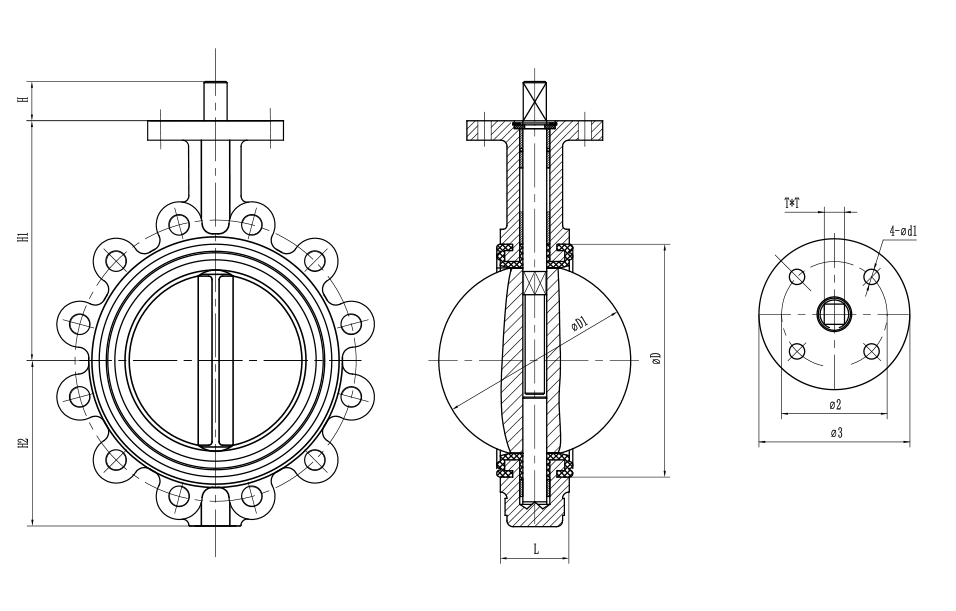

Paraments of Two Shaft Lug Butterfly Valve

| SIZE | øD | øD1 | L | L1 | H | H1 | H2 | ∅2 | ø3 | 4-ødl | T*T |

|---|---|---|---|---|---|---|---|---|---|---|---|

| DN50 | 76.3 | 52.8 | 43 | 46 | 30 | 140 | 60 | 70 | 90 | 10 | 11*11 |

| DN65 | 89 | 64.6 | 45.6 | 49 | 30 | 150 | 67 | 70 | 90 | 10 | 11*11 |

| DN80 | 103.9 | 79.1 | 45.6 | 48 | 30 | 160 | 87 | 70 | 90 | 10 | 11*11 |

| DN100 | 135 | 104.4 | 52.0 | 56 | 30 | 180 | 105 | 70 | 90 | 10 | 11*11 |

| DN125 | 159 | 123.3 | 56.0 | 60 | 30 | 190 | 118 | 70 | 90 | 10 | 14*14 |

| DN150 | 188.4 | 155.6 | 56.0 | 60 | 30 | 210 | 130 | 70 | 90 | 10 | 14*14 |

| DN200 | 238.2 | 202.5 | 60.0 | 64 | 35 | 235 | 166 | 102 | 125 | 12 | 17*17 |

| DN250 | 292.4 | 250.5 | 68.0 | 72 | 35 | 270 | 197 | 102 | 125 | 12 | 22*22 |

| DN300 | 344.2 | 301.6 | 78.0 | 83 | 35 | 305 | 231 | 102 | 125 | 12 | 22*22 |

| DN350 | 375.2 | 333.4 | 78.0 | 83 | 35 | 360 | 255 | 125 | 150 | 14 | 22*22 |

| DN400 | 439.5 | 389.6 | 102.0 | 106 | 50 | 381 | 293 | 140 | 175 | 18 | 27*27 |

| DN450 | 490.5 | 440.5 | 114.0 | 118 | 50 | 425 | 325 | 140 | 175 | 18 | 27*27 |

| DN500 | 535.4 | 491.6 | 127.0 | 132 | 50 | 470 | 363 | 140 | 175 | 18 | 36*36 |

| DN600 | 653.7 | 592.5 | 153 | 159 | 60 | 565 | 425 | 165 | 210 | 22 | 36*36 |

Manufacture Process of Lug Butterfly Valve

Certificates of ZFA Valve

WRAS

CE

ISO 9001

EAC Russia