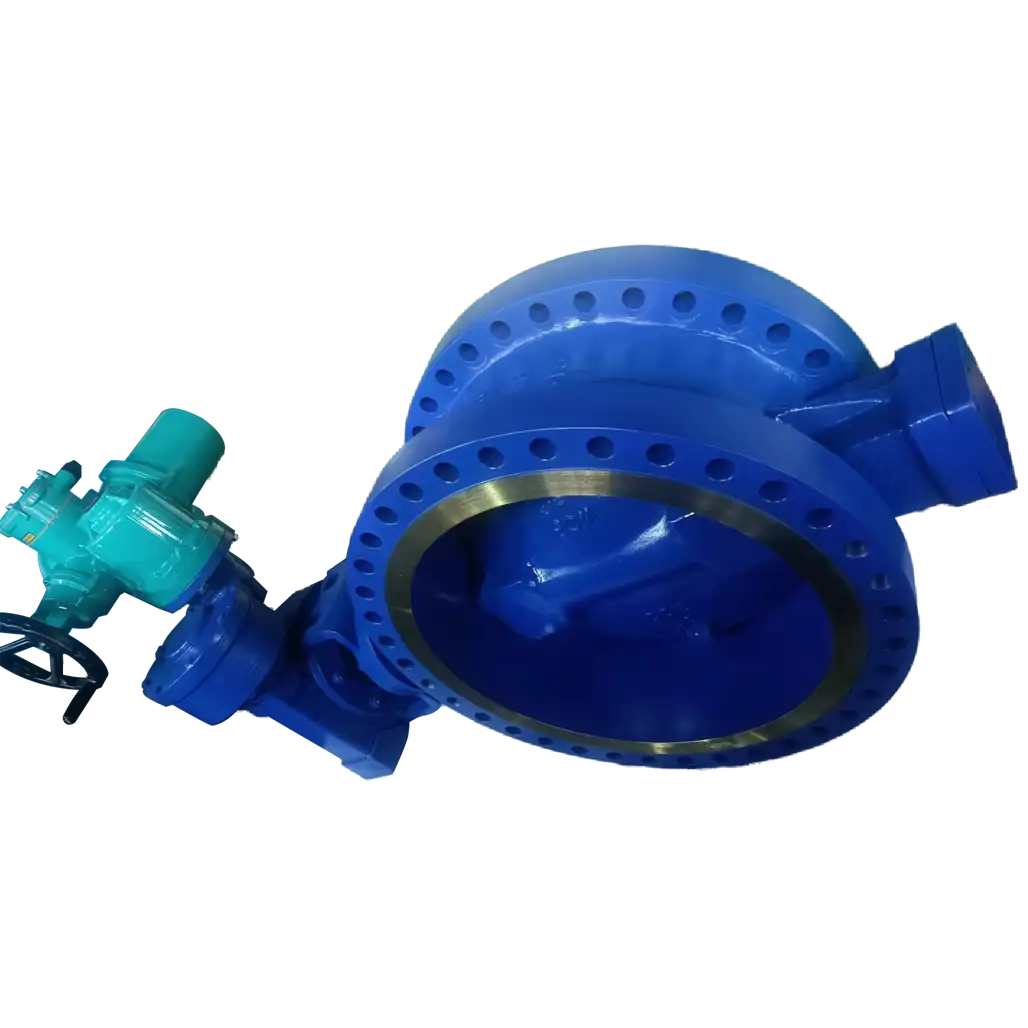

Electric Triple Eccentric Butterfly Valve

Basic Info

Detailes of Electric Triple Eccentric Butterfly Valve.

- Triple eccentric structural design: The triple eccentric shaft butterfly valve adopts a triple eccentric design to reduce friction during the opening and closing process of the valve and extend its service life.

- High-quality sealing: The triple-eccentric butterfly valve adopts high-quality sealing materials and unique sealing structure to ensure the sealing performance of the butterfly valve under various working conditions. The material is generally all metal or metal and graphite superimposed. Its sealing structure is generally integral or multi-layered, including the valve seat, valve plate sealing surface and compensation mechanism, which can effectively prevent medium leakage and ensure system safety.

- Small flow resistance: The three-eccentric shaft butterfly valve has small flow resistance, so it can reduce energy consumption and reduce fluid transportation resistance when transporting fluid. In addition, the valve’s opening adjustment range is large, which can meet flow requirements under different working conditions.

- Electric triple-eccentric butterfly valve: It can be controlled remotely, opens and closes quickly, and is highly safe for pipeline systems and materials.

Standard of Electric Triple Eccentric Butterfly Valve

| ITEM | Standard |

| Design | EN593 | API609 |

| Face to Face | EN558 | ISO5752 | API608 | BS5155-4 |

| Top Flange | ISO5211 |

| Flange Drilling | PN6 | PN10 | PN16 | ASME B16.5 CL150 | JIS 10K |

| Pressure Rating | PN6 | PN10 | PN16 | PN25 | CL150 | JIS 10K |

| Tightness Test | ISO5208 | API598 | EN12266-1 |

Material of Electric Triple Eccentric Butterfly Valve

| Part Name | Material/Method |

| Body | Ductile Iron, Casting Iron, WCB, LCB/LCC, Stainless Steel, Duplex Stainless Steel, Aluminium Bronze |

| Disc | Ductile Iron(Coated/Lined), WCB, LCB/LCC, Stainless Steel, Duplex Stainless Steel, Aluminium Bronze |

| Seat | Metal+Flexible Graphite |

| Stem | 304, 316, 420(2Cr13), 431, 1.4462, 17-4PH, Monel |

| Actuator | Worm Gear, Electric, Pneumatic |

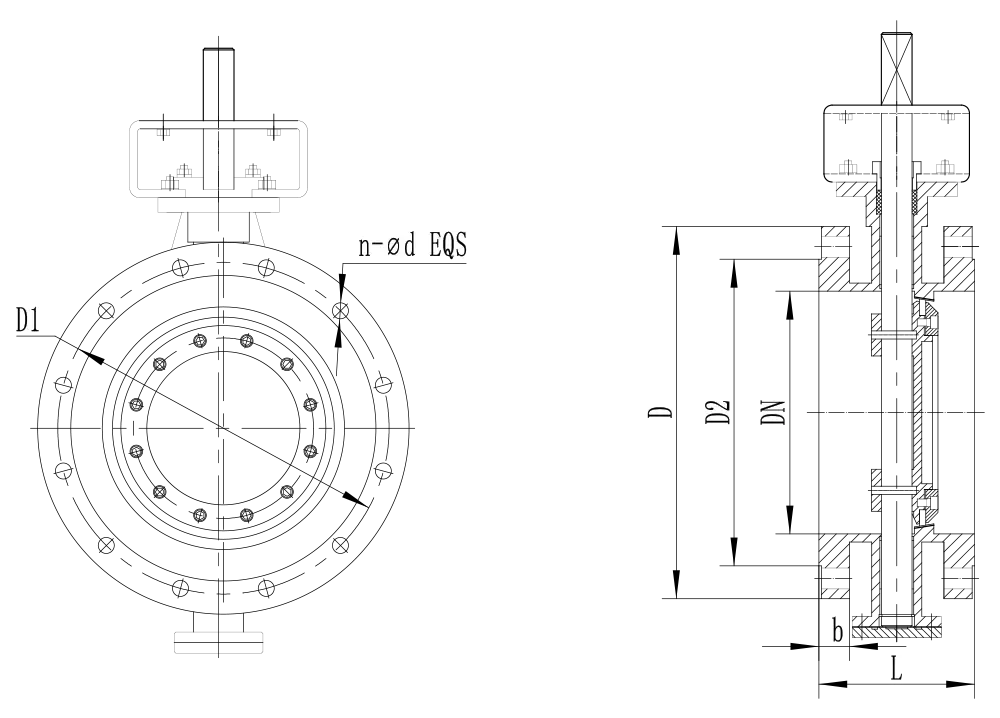

Paraments

| SIZE | PN16 | 150LB | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| D | D1 | D2 | b | n-ød | L | D | D1 | D2 | b | n-ød | L | |

| DN100 | 220 | 180 | 158 | 20 | 8-ø18 | 127±2 | 230 | 191 | 157 | 24 | 8-ø19 | 127±3.3 |

| DN125 | 250 | 210 | 188 | 22 | 8-ø18 | 140±2 | 255 | 216 | 186 | 24 | 8-ø22 | 140±3.3 |

| DN150 | 285 | 240 | 212 | 22 | 8-ø22 | 140±2 | 280 | 241 | 216 | 26 | 8-ø22 | 140±3.3 |

| DN200 | 340 | 295 | 268 | 24 | 12-ø22 | 152±2 | 345 | 299 | 270 | 29 | 8-ø22 | 152±3.3 |

| DN250 | 405 | 355 | 320 | 26 | 12-ø26 | 165±2 | 405 | 362 | 324 | 31 | 12-ø26 | 165±3.3 |

| DN300 | 460 | 410 | 378 | 28 | 12-ø26 | 178±2 | 485 | 432 | 381 | 32 | 12-ø26 | 178±3.3 |

| DN350 | 520 | 470 | 438 | 30 | 16-ø26 | 190±2 | 535 | 476 | 413 | 35 | 12-ø29 | 190±3.3 |

| DN400 | 580 | 525 | 490 | 32 | 16-ø30 | 216±2 | 595 | 540 | 470 | 37 | 16-ø29 | 216±3.3 |

| DN450 | 640 | 585 | 550 | 40 | 20-ø30 | 222±2 | 635 | 578 | 533 | 40 | 16-ø32 | 222±3.3 |

| DN500 | 715 | 650 | 610 | 44 | 20-ø33 | 229±2 | 700 | 635 | 584 | 43 | 20-ø32 | 229±3.3 |

| DN600 | 840 | 770 | 725 | 54 | 20-ø36 | 267±3 | 815 | 749 | 692 | 48 | 20-ø35 | 267±3.3 |

Manufacture Process

Certificates

WRAS

CE

ISO 9001

EAC Russia