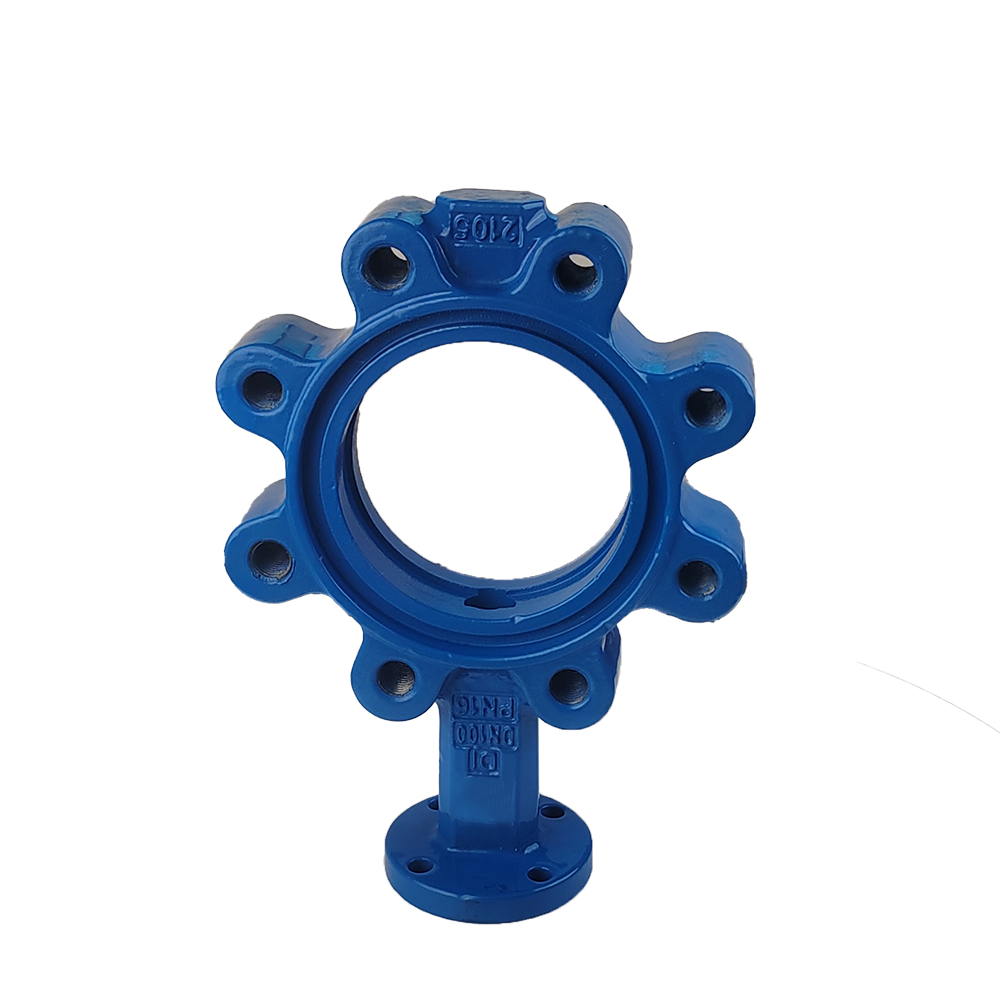

Ducitle Iron Fully Lug Butterfly Valve Body

Basic Info

- Lug center thread form: Fully Lug butterfly valve adopts lug center thread form, that is, by installing the butterfly valve on the pipe flange, it can effectively maintain the position of the valve and avoid instability of the valve caused by working pressure.

- Centerline design: This lug butterfly valve adopts a centerline design, which makes the valve action more stable and accurate, reduces the opening and closing torque, and improves operating performance and ease of use.

-

Body: Made of ductile iron for excellent strength, toughness and corrosion resistance.

-

Full Lug Design: Easy to install and remove, can be installed between flanges without additional support.

-

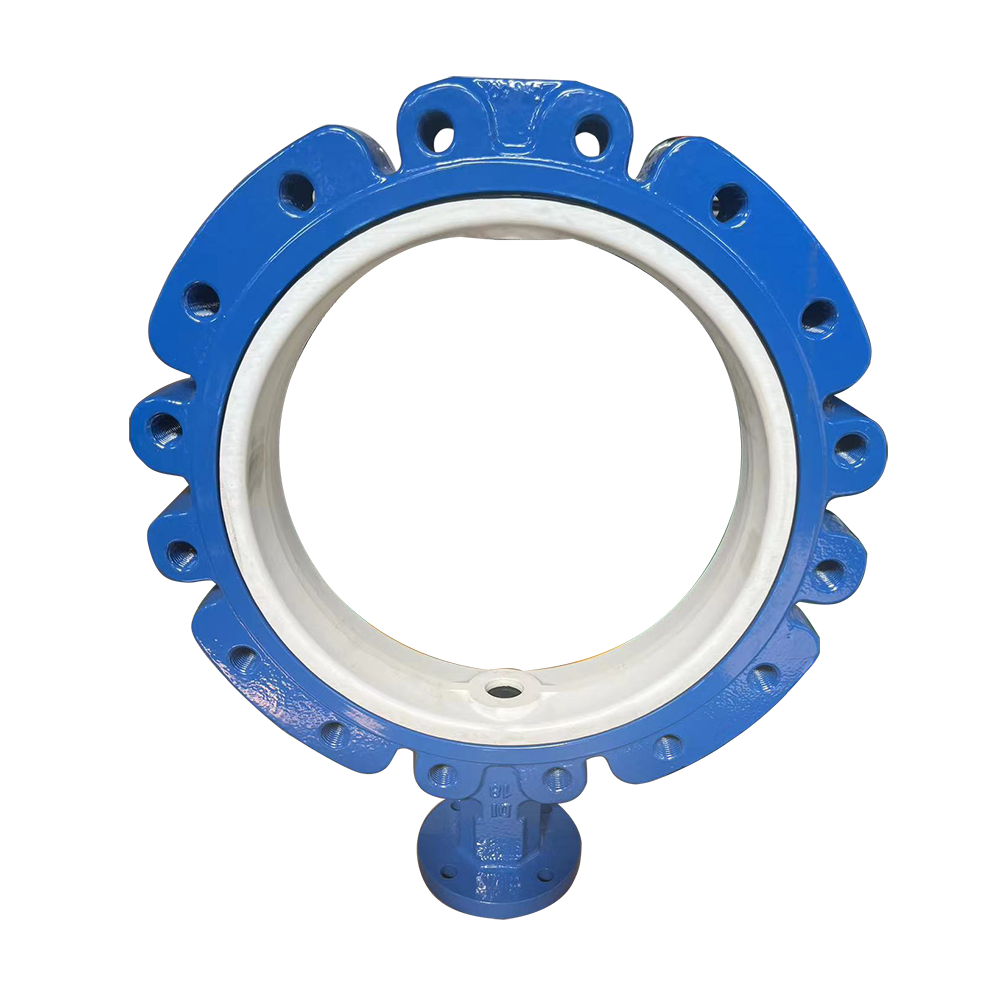

Soft Seat: Excellent sealing performance to minimize leakage and ensure tight shutoff.

-

Bidirectional Flow: The valve can effectively control flow in both directions, enhancing its versatility in system design.

Paraments

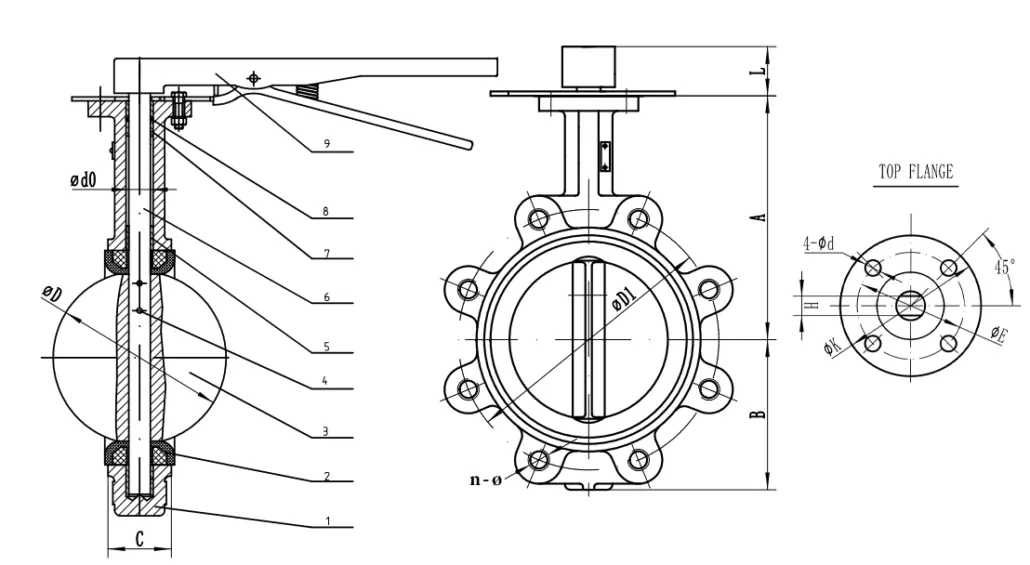

| DN | A | B | C | D | L | D1 | n-ø | K | E | 4-ød | d0 | |

| mm | inch | |||||||||||

| 50 | 2″ | 161 | 80 | 42 | 52.9 | 32 | 120 | 4-ø23 | 77 | 57.15 | 4-ø6.7 | 12.6 |

| 65 | 2.5″ | 175 | 89 | 44.7 | 64.5 | 32 | 136.2 | 4-ø26.5 | 77 | 57.15 | 4-ø6.7 | 12.6 |

| 80 | 3″ | 181 | 95 | 45.2 | 78.8 | 32 | 160 | 8-ø18 | 77 | 57.15 | 4-ø6.7 | 12.6 |

| 100 | 4″ | 200 | 114 | 52.1 | 104 | 32 | 185 | 4-ø24.5 | 92 | 69.85 | 4-ø10.3 | 15.77 |

| 125 | 5″ | 213 | 127 | 54.4 | 123.3 | 32 | 215 | 4-ø23 | 92 | 69.85 | 4-ø10.3 | 18.92 |

| 150 | 6″ | 226 | 139 | 55.8 | 155.6 | 32 | 238 | 4-ø25 | 92 | 69.85 | 4-ø10.3 | 18.92 |

| 200 | 8″ | 260 | 175 | 60.6 | 202.5 | 45 | 295 | 4-ø25 | 115 | 88.9 | 4-ø14.3 | 22.1 |

| /4-ø23 | ||||||||||||

| 250 | 10″ | 292 | 203 | 65.6 | 250.5 | 45 | 357 | 4-ø29 | 115 | 88.9 | 4-ø14.3 | 28.45 |

| 300 | 12″ | 337 | 242 | 76.9 | 301.6 | 45 | 407 | 4-ø29 | 140 | 107.95 | 4-ø14.3 | 31.6 |

| 350 | 14″ | 368 | 267 | 76.5 | 333.3 | 467 | 4-ø30 | 140 | 107.95 | 4-ø14.3 | 31.6 | |

| 400 | 16″ | 400 | 309 | 86.5 | 389.6 | 51.2 | 515 | 4-ø26 | 197 | 158.75 | 4-ø20.6 | 33.15 |

| /72 | /525 | /4-ø30 | ||||||||||

| 450 | 18″ | 422 | 328 | 105.6 | 440.51 | 51.2 | 565 | 4-ø26 | 197 | 158.75 | 4-ø20.6 | 38 |

| /72 | /585 | /4-ø30 | ||||||||||

| 500 | 20″ | 480 | 361 | 131.8 | 491.6 | 64.2 | 620 | 4-ø26 | 197 | 158.75 | 4-ø20.6 | 41.15 |

| /82 | /650 | /4-ø33 | ||||||||||

| 600 | 24″ | 562 | 459 | 152 | 592.5 | 70.2 | 725 | 20-ø30 | 276 | 215.9 | 4-ø22.2 | 50.65 |

| /82 | /770 | /20-ø36 | ||||||||||

| 700 | 28″ | 624 | 520 | 163 | 695 | 66 | 840 | 24-ø30 | 300 | 254 | 8-ø18 | 55/63.35 |

| /82 | /20-ø36 | |||||||||||

| 800 | 32″ | 672 | 591 | 188 | 794.7 | 66 | 950 | 24-ø33 | 300 | 254 | 8-ø18 | 55/63.35 |

| /82 | /24-ø39 | |||||||||||

| 900 | 36″ | 720 | 656 | 203 | 864.7 | 118 | 1050 | 24-ø33 | 300 | 254 | 8-ø18 | 75 |

| 1000 | 40″ | 800 | 721 | 216 | 965 | 142 | 1160 | 24-ø36 | 300 | 254 | 8-ø18 | 85 |

Manufacture Process

Certificates

WRAS

CE

ISO 9001

EAC Russia