Pneumatic Wafer Butterfly Valve PN10/16/CL150

Features of Pneumatic Butterfly Valve

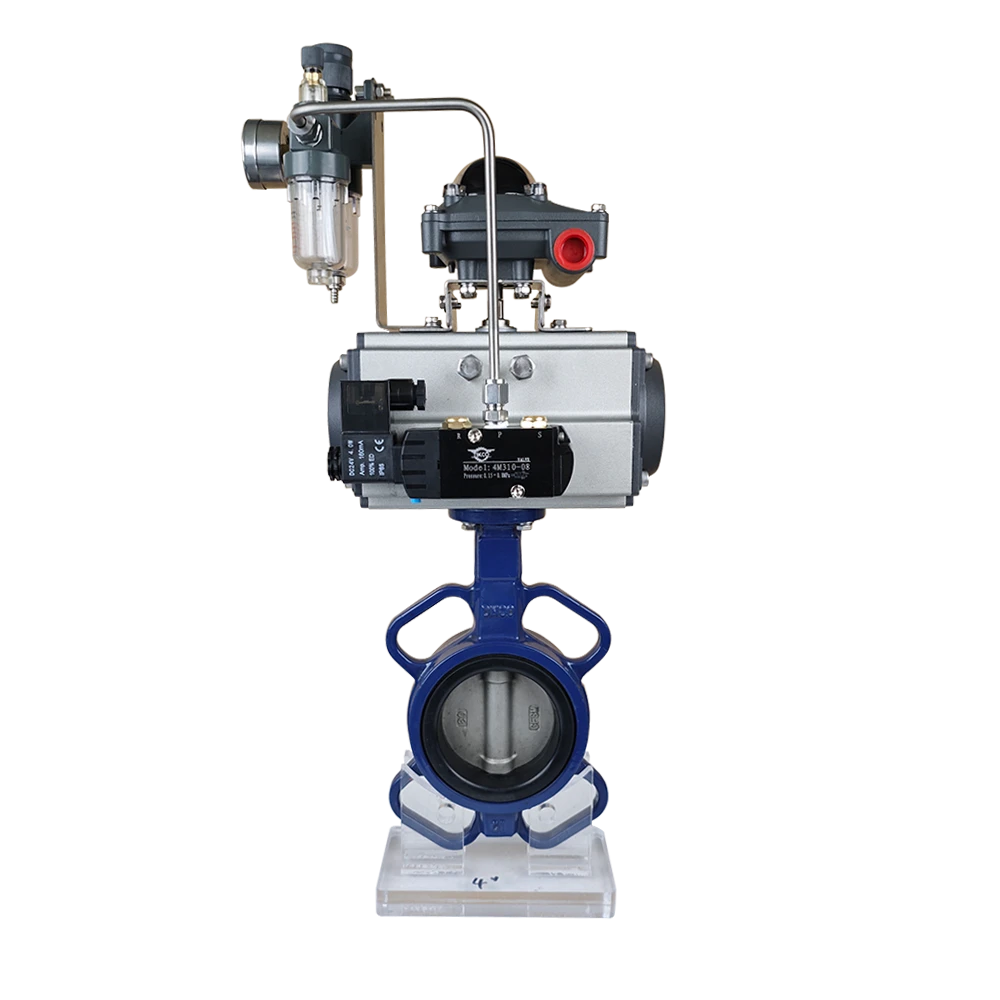

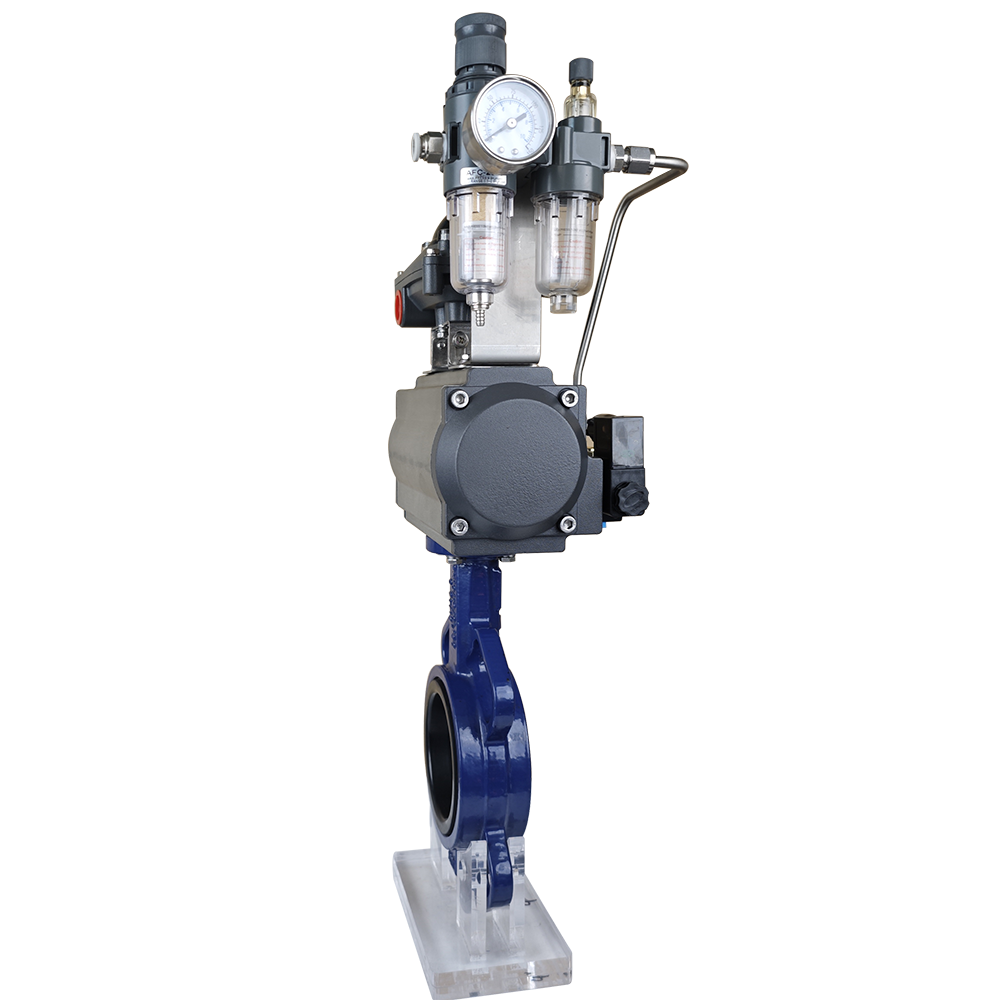

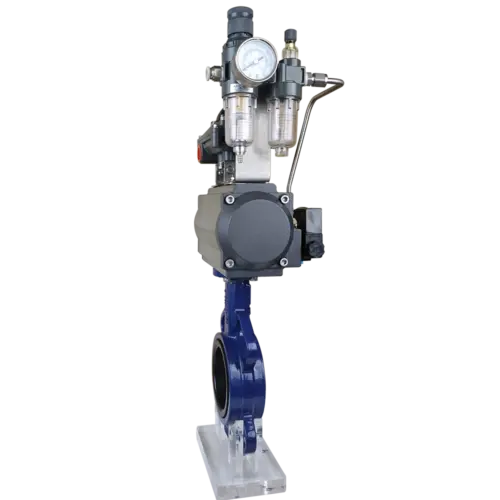

Composition and function of the triplex pneumatic butterfly valve

Filter

Pressure Regulating Valve

Lubricator

When choose a pneumatic actuator, there are several important issues to consider:

- Match: Make sure the pneumatic actuator selected matches the required valve size and type to ensure the system will function properly.

- Control mode: According to the process requirements and control needs, select the appropriate pneumatic actuator control mode, such as double-acting or single-acting actuator.

- Environmental conditions: Consider the environmental conditions of the installation location, including temperature, humidity, corrosion, etc., and select pneumatic actuator materials and protection levels that meet the requirements.

- Control signals: Determine the control signal types and interface standards required so that the pneumatic actuator is compatible with the control system.

Basic Info of Pneumatic Butterfly Valve

Material

| Part Name | Material/Method |

| Body | Ductile Iron, Casting Iron, WCB, LCB/LCC, Stainless Steel, Duplex Stainless Steel, Aluminium Bronze |

| Disc | Ductile Iron(Coated/Lined), WCB, LCB/LCC, Stainless Steel, Duplex Stainless Steel, Aluminium Bronze |

| Seat | Rubber(EPDM/NBR/VITON), Nature Rubber, Silicon Rubber, PU, HNBR, Hypalon |

| Stem | 304, 316, 420(2Cr13), 431, 1.4462, 17-4PH, Monel |

| Actuator | Pneumatic, Handlever, Worm Gear, Electric |

Technical Parameters

| ITEM | Standard |

| Design | EN593 | API609 |

| Face to Face | EN558 | ISO5752 | API608 | BS5155-4 |

| Top Flange | ISO5211 |

| Flange Drilling | PN6 | PN10 | PN16 | ASME B16.5 CL150 | JIS 10K |

| Pressure Rating | PN6 | PN10 | PN16 | PN25 | CL150 | JIS 10K |

| Tightness Test | ISO5208 | API598 | EN12266-1 |

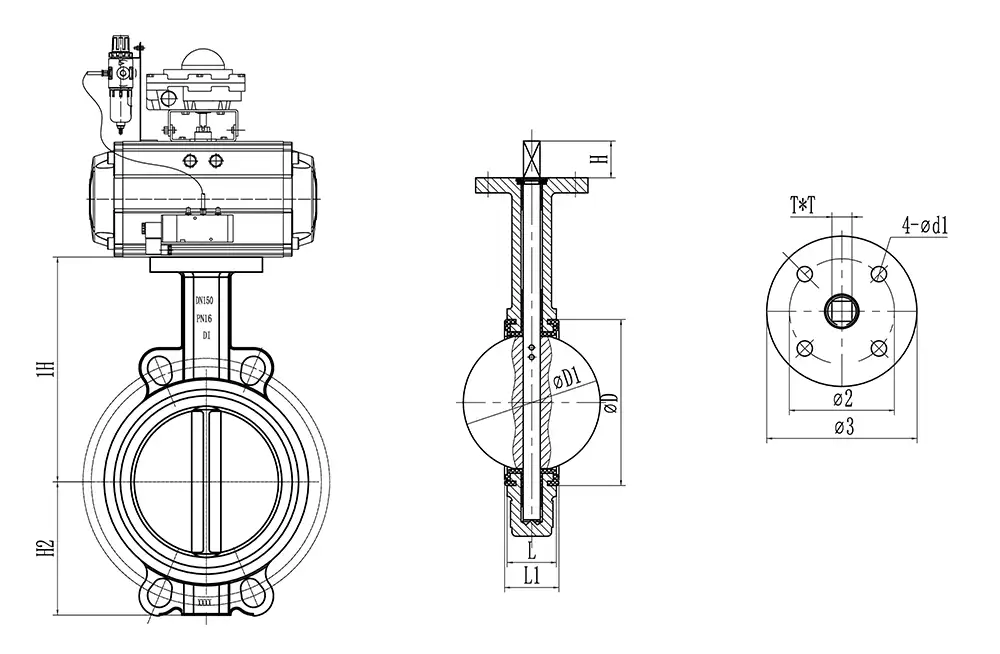

Dimensions of Pneumatic Wafer Butterfly Valve

| SIZE | øD | øD1 | L | H | H1 | H2 | ø2 | ø3 | 4-ød1 | T*T |

| DN40 | 72 | 43 | 33 | 25 | 121 | 61 | 50 | 65 | 7 | 9 |

| DN50 | 76.3 | 52.8 | 42 | 25 | 131 | 66 | 50 | 65 | 7 | 9 |

| DN65 | 89 | 64.6 | 44.7 | 25 | 142 | 71 | 50 | 65 | 7 | 9 |

| DN80 | 103.9 | 79.1 | 45 | 25 | 150 | 83 | 50 | 65 | 7 | 9 |

| DN100 | 135 | 104.4 | 51.2 | 25 | 170 | 102 | 70 | 90 | 10 | 11 |

| DN125 | 159 | 123.3 | 54.4 | 25 | 184 | 117 | 70 | 90 | 10 | 14 |

| DN150 | 188.4 | 155.6 | 55 | 25 | 200 | 130 | 70 | 90 | 10 | 14 |

| DN200 | 238.2 | 202.5 | 58.8 | 35 | 240 | 162 | 70 | 90 | 10 | 17 |

| DN250 | 292.4 | 250.5 | 65.7 | 35 | 270 | 196 | 102 | 125 | 12 | 22 |

| DN300 | 344.2 | 301.6 | 76 | 35 | 310 | 216 | 102 | 125 | 12 | 22 |

| DN350 | 375.2 | 333.4 | 76.5 | 45 | 368 | 260 | 102 | 140 | 12 | 22 |

| DN400 | 439.5 | 389.6 | 85.7 | 50 | 400 | 315 | 140 | 175 | 18 | 27 |

| DN450 | 490.5 | 440.5 | 104.6 | 50 | 422 | 340 | 140 | 175 | 18 | 27 |

| DN500 | 535.4 | 491.6 | 130.2 | 55 | 480 | 379 | 140 | 175 | 18 | 32 |

| DN600 | 654.3 | 592.5 | 151.3 | 68 | 562 | 438 | 165 | 210 | 23 | 36 |

Application of Pneumatic Wafer Butterfly Valve

1. Water treatment facilities: For water treatment projects, pneumatic butterfly valves help regulate the inflow of raw water, the flow rate of treated water, and the outflow of wastewater.

2. Petrochemical industry: The petrochemical industry requires precise control of fluid flow and pressure. This makes pneumatic wafer butterfly valves ideal for regulating fluid flow in refineries, chemical tanks, gas processing units, and other facilities. Its rugged design can withstand the high temperatures and pressures common in this industry.

3. Power generation: During the power generation process, steam turbines need to precisely regulate inlet and outlet flows. Pneumatic butterfly valves minimize energy losses by regulating steam pressure.

4. Chemical industry: In chemical plants, pneumatic wafer butterfly valves can be used in processes such as mixing, separation, reaction, filtration, transportation, and storage of chemicals. Their function is to seal and control the flow of corrosive, toxic, or hazardous substances.

5. Food processing industry: Pneumatic butterfly valves are suitable for conveying, filling, batching, and metering operations in factories that produce beverages, dairy products, canned foods, and baked goods.

6. HVAC system: Butterfly valves regulate cold and hot water in HVAC systems. Automated operation improves efficiency and reduces manual intervention.

Manufacture Process of Butterfly Valve

Certificates

WRAS

CE

ISO 9001

EAC Russia