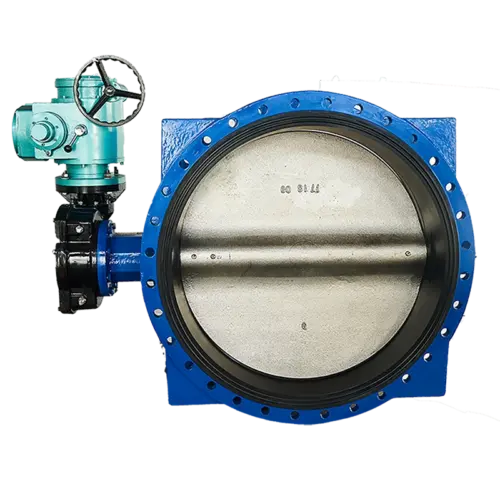

Wholesale Wafer PTFE Fully Lined Multi-Standard Butterfly Valve DN200 PN16

Features of Multi-Standard Butterfly Valve

- The wafer-style valve body is engineered to fit between flanges of various standards. ?The body of Multi-Standard Butterfly Valve has a universal face-to-face dimension (e.g., per API 609 or EN 558) and bolt hole alignment to accommodate these standards without modification.

-

-

- PN10/PN16 (European standard, EN 1092-1): Common in water and wastewater systems, rated for 10 or 16 bar.

- ANSI/ASME B16.5 Class 150: North American standard, widely used in chemical and industrial applications.

- DIN 2501: German standard, often overlapping with PN10/PN16.

- BS 4504: British standard, compatible with PN10/PN16.

- JIS B2220 (5K/10K): Japanese standard, used in Asian markets.

-

2. Corrosion resistance: PTFE fully lined butterfly valve has excellent corrosion resistance to various corrosive liquids, including strong acids, strong alkalis, etc.

3. Temperature Range: PTFE fully lined Multi-Standard Butterfly Valve can withstand higher temperatures than EPDM,while It has a temperature range of approximately -250°C to +260°C (-418°F to +500°F).

4. Versatility: PTFE is also called “Plastic King” in China, so it is suitable for different types of media, whether it is corrosive or non-corrosive fluid.

5. Low Friction: PTFE has a low coefficient of friction, reducing wear on valve components, as a result, it can increases service life and reduces maintenance.

Basic Info of PTFE Fully Lined Butterfly Valve

Material

| Part Name | Material/Method |

| Body | Ductile Iron, Casting Iron, WCB, LCB/LCC, Stainless Steel, Duplex Stainless Steel, Aluminium Bronze |

| Disc | PTFE Fully Lined Ductile Iron, WCB, LCB/LCC, Stainless Steel, Duplex Stainless Steel, Aluminium Bronze |

| Seat | Rubber(EPDM/NBR/VITON), Nature Rubber, Silicon Rubber, PU, HNBR, Hypalon |

| Stem | 304, 316, 420(2Cr13), 431, 1.4462, 17-4PH, Monel |

| Actuator | Handlever, Worm Gear, Electric, Pneumatic |

Technical Parameters

| ITEM | Standard |

| Design | EN593 | API609 |

| Face to Face | EN558 | ISO5752 | API608 | BS5155-4 |

| Top Flange | ISO5211 |

| Flange Drilling | PN6 | PN10 | PN16 | ASME B16.5 CL150 | JIS 10K |

| Pressure Rating | PN6 | PN10 | PN16 | PN25 | CL150 | JIS 10K |

| Tightness Test | ISO5208 | API598 | EN12266-1 |

Paraments of PTFE Fully Lined Butterfly Valve

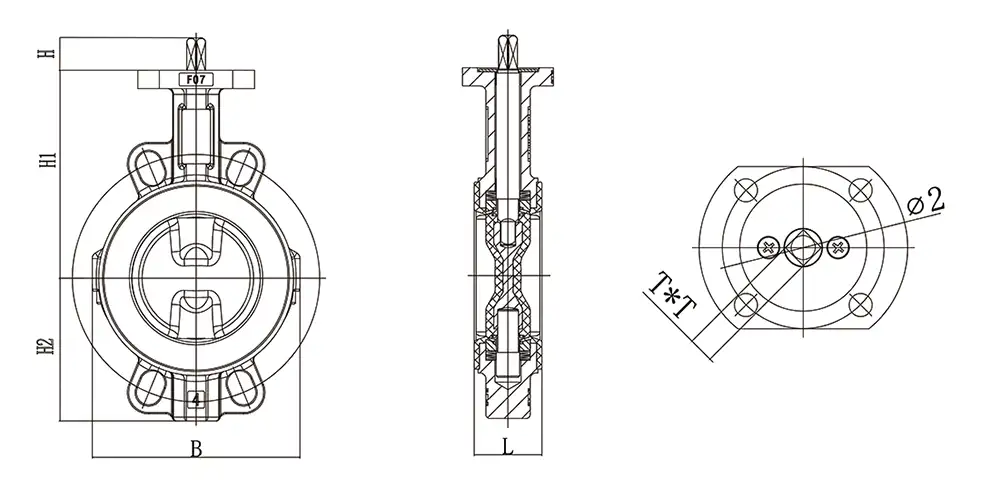

| SIZE | L | H1 | H2 | B | ø2 | T*T | H |

| DN50 | 43 | 134 | 68 | 100 | F05 | 9*9 | 25 |

| DN65 | 46 | 145 | 78 | 120 | F05 | 9*9 | 25 |

| DN80 | 46 | 150 | 80 | 140 | F05 | 9*9 | 25 |

| DN100 | 52 | 160 | 110 | 160 | F07 | 11*11 | 25 |

| DN125 | 56 | 178 | 130 | 190 | F07 | 14*14 | 25 |

| DN150 | 56 | 197 | 140 | 220 | F07 | 14*14 | 25 |

| DN200 | 60 | 239 | 175 | 277 | F10 | 17*17 | 30 |

| DN250 | 68 | 278 | 215 | 330 | F10 | 22*22 | 30 |

| DN300 | 78 | 315 | 250 | 380 | F12 | 22*22 | 30 |

| DN350 | 78 | 355 | 255 | 440 | F12 | 22*22 | 30 |

Manufacture Process of Butterfly Valve

Certificates

WRAS

CE

ISO 9001

EAC Russia