Iron is undoubtedly one of the most used materials worldwide. Ductile iron and cast iron are two of the most common types. They have many applications in different industries. We are going to discuss ductile iron VS cast iron. What are the advantages and disadvantages of both of these? From finding the difference between cast iron and…

Introduction to butterfly valve leakage rate Butterfly valves are ubiquitous in various industries, providing effective flow control in pipelines. An important aspect of their performance is their leakage rate, which determines how well they prevent fluid leakage when closed. This article takes an in-depth look at the complexity of butterfly valve leakage rates, exploring the…

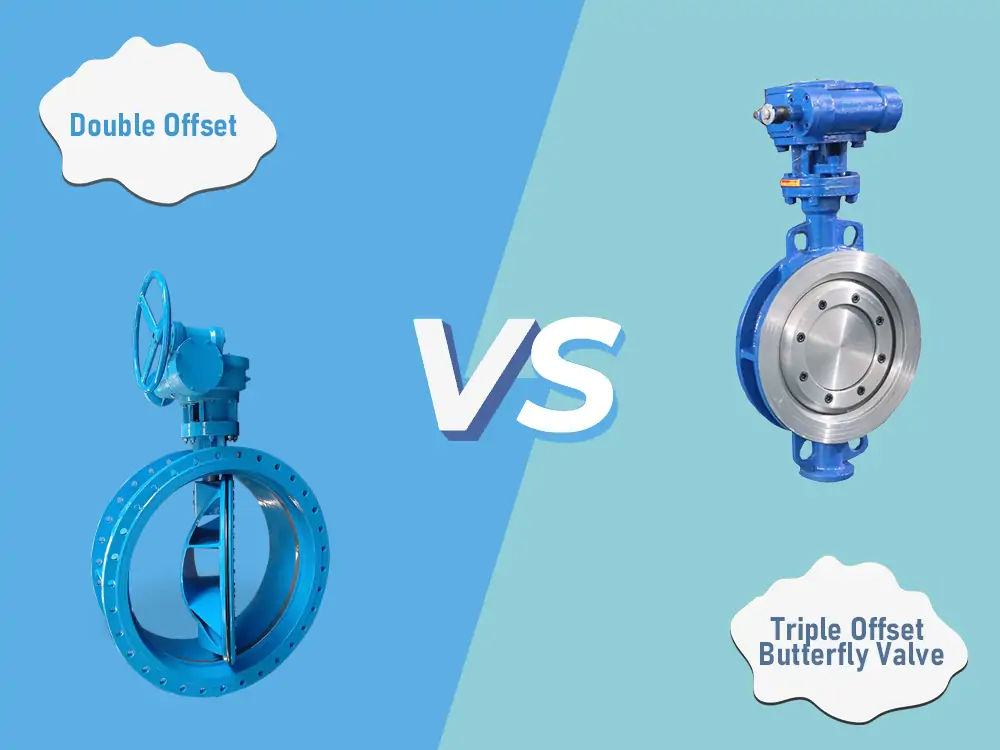

In many industries, butterfly valves are the staple for efficient flow control. Their simple designs facilitate precise fluid movement through pipelines, making them efficient and helping to save time. This makes them a common option for many industries in their applications. Butterfly valves come in different types. The most common are double and triple-offset butterfly valves. These two valves…

Butterfly valves are indispensable components in various industries. They serve critical roles in regulating fluid flow. Their versatility, cost-effectiveness, and ease of operation make them popular choices. Selecting the appropriate butterfly valve entails considering several factors. This is to ensure optimal performance and longevity. This guide explores the intricacies of choosing the suitable butterfly valve. It covers essential considerations, types,…

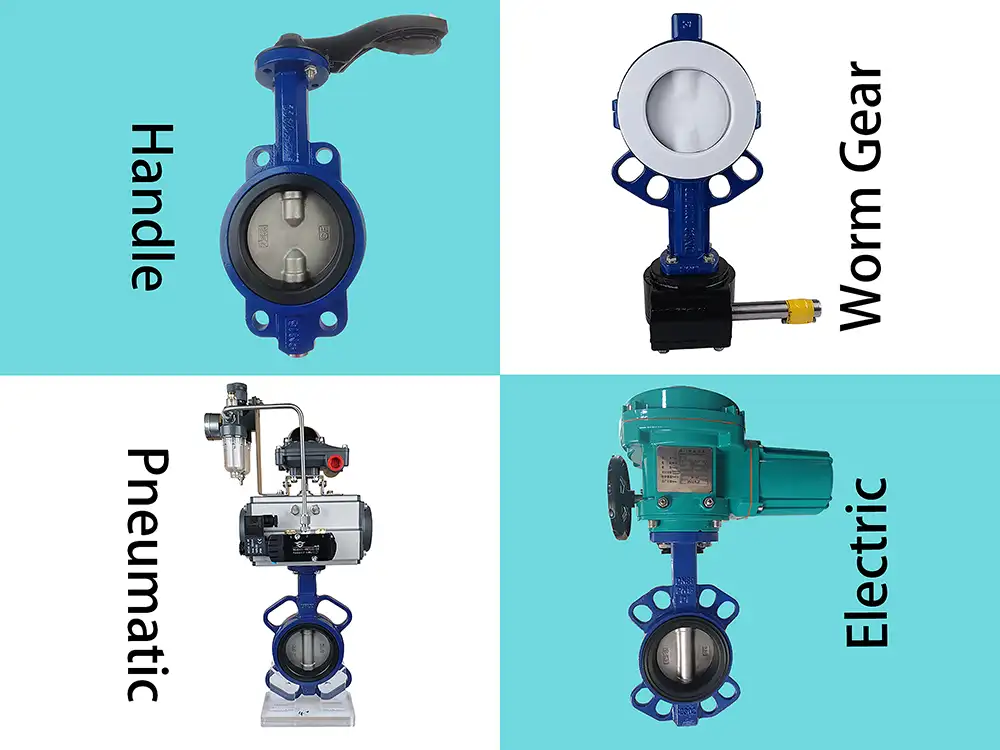

The opening and closing of the butterfly valve requires a power, and the device that provides this power is called an actuator. The actuator controls the opening and closing of the butterfly valve by providing a position signal to realize the circulation and stage functions of the pipeline system. Therefore, the actuator is an indispensable…

Brief introduction Butterfly valve is an important valve type for fluid control. In the selection process, the correct selection of valve size is crucial because it directly affects the performance, safety and economy of the system. Let us discuss the applicable occasions and the key points of butterfly valve size selection. 1. Key Butterfly Valve…

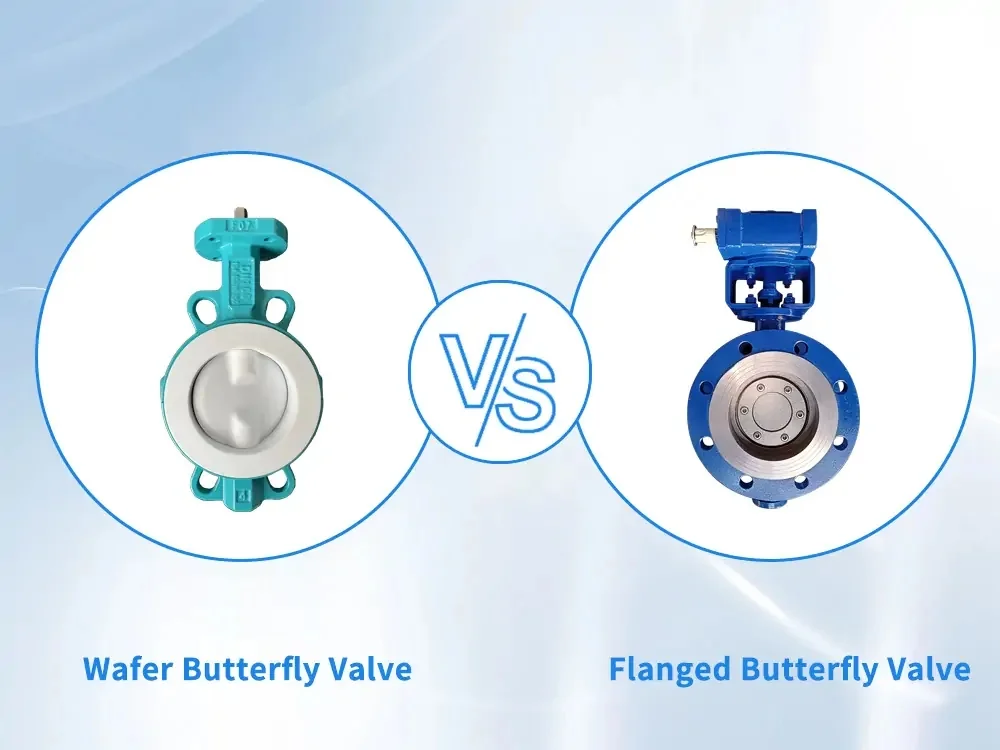

Valves play an important role in fluid control. Butterfly valves are among the most used valves today. When it comes to fluid control systems, these valves are used for better operation. They help enhance performance and keep things in check. Of all the different valve choices, wafer and flanged valves are popular. The purpose of…

The AWWA C504 butterfly valve is a special type of valve used in water distribution systems. It is designed to meet the standards set by the American Water Works Association (AWWA) and is commonly used in municipal water treatment plants, distribution systems and other industries for water treatment, plumbing, industrial fluids, etc. The valve is…

Introduction: A check valve is critical in any residential or commercial space and is used in many systems. But do you know what a check valve is? A check valve is present in pipelines, pump outlets, and more. The main purpose is to prevent the backflow of fluid. Thus, this prevention helps the equipment remain…

The PTFE Butterfly Valves seat adopts one-time molding technology, and the back lining is closely combined with high elastic rubber and PTFE, which reduces the deformation of the valve seat and ensures zero leakage of the valve under rated pressure. At the same time, the f4 valve seat adopts the most popular wide flange form, which…